Product Similar To :

KenFeed™ Mini • End Mill • Cylindrical Shank • Inch

Copy milling cutter for multiple materials.

Material Number3652893

ISO Catalog IDKF063WP0302C063L100ANSI Catalog IDKF063WP0302C063L100

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Shank - Cylindrical Plain

Milling - Through Coolant

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 3652893 |

| ISO Catalog ID | KF063WP0302C063L100 |

| ANSI Catalog ID | KF063WP0302C063L100 |

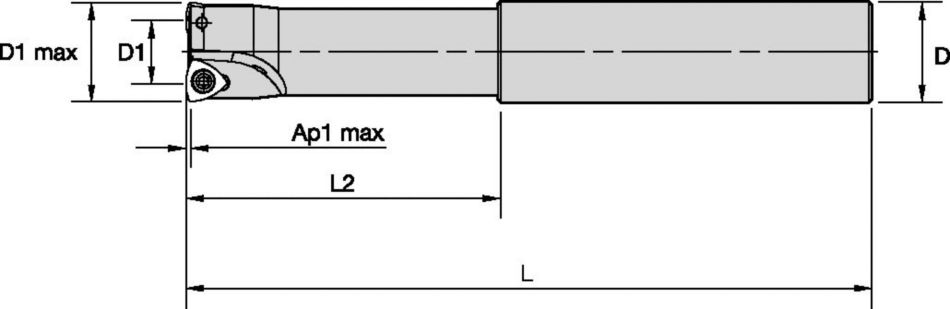

| [D1MAX] Maximum Cutting Diameter | 15.875 mm |

| [D1MAX] Maximum Cutting Diameter | 0.625 in |

| [D1] Effective Cutting Diameter | 9.98 mm |

| [D1] Effective Cutting Diameter | 0.393 in |

| [D] Adapter / Shank / Bore Diameter | 15.875 mm |

| [D] Adapter / Shank / Bore Diameter | 0.625 in |

| [L] Overall Length | 85.4 mm |

| [L] Overall Length | 3.362 in |

| [L2] Head Length | 25.4 mm |

| [L2] Head Length | 1 in |

| [AP1MAX] 1st Maximum Cutting Depth | 0.84 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.033 in |

| Number of Inserts | 2 |

| Maximum Ramping Angle | 8.5 |

| Max RPM | 20050 |

| Gage Insert | WP..0302. |

| Weight Pounds | 0.25 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Shank - Cylindrical Plain

Milling - Through Coolant

Pocketing

Features and benefits

- Engineered to use with small machines and/or components using high-feed milling strategies.

- Fine-pitch cutters boost productivity; able to run up to 0,05 IPT.

- Pocketing, ramping, and helical interpolations.

- First choice above 3 x D applications.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .LD.. | .027 | .070 | .121 | .019 | .049 | .081 | .017 | .042 | .068 | .016 | .040 | .063 | .015 | .039 | .062 | .LD.. |

| .LN.. | .027 | .070 | .121 | .019 | .049 | .081 | .017 | .042 | .068 | .016 | .040 | .063 | .015 | .039 | .062 | .LN.. |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KC510M | KC522M | KC725M | KCPM20 | KCPK30 | |||||||||||

| P | 1 | – | – | – | 1300 | 1130 | 1060 | 1030 | 900 | 840 | 2170 | 1910 | 1760 | 1780 | 1560 | 1450 |

| 2 | – | – | – | 1080 | 950 | 790 | 860 | 760 | 640 | 1340 | 1210 | 1090 | 1100 | 1000 | 900 | |

| 3 | – | – | – | 1000 | 840 | 700 | 790 | 670 | 550 | 1210 | 1090 | 1000 | 1000 | 900 | 820 | |

| 4 | 960 | 780 | 660 | 890 | 730 | 590 | 710 | 590 | 470 | 910 | 840 | 760 | 740 | 690 | 620 | |

| 5 | – | – | – | 730 | 660 | 590 | 590 | 530 | 470 | 1090 | 980 | 900 | 1020 | 910 | 830 | |

| 6 | – | – | – | 650 | 490 | 400 | 520 | 400 | 310 | 760 | 660 | 570 | 620 | 540 | – | |

| M | 1 | – | – | – | 800 | 710 | 650 | 670 | 590 | 540 | 880 | 790 | 680 | 820 | 720 | 620 |

| 2 | – | – | – | 730 | 620 | 520 | 610 | 520 | 430 | 800 | 700 | 620 | 730 | 640 | 550 | |

| 3 | – | – | – | 550 | 480 | 370 | 460 | 400 | 310 | 640 | 570 | 490 | 570 | 520 | 460 | |

| K | 1 | 1150 | 1040 | 940 | 900 | 820 | 720 | – | – | – | 1420 | 1280 | 1150 | 1160 | 1050 | 940 |

| 2 | 910 | 820 | 760 | 710 | 640 | 590 | – | – | – | 1130 | 1010 | 920 | 920 | 830 | 760 | |

| 3 | 770 | 680 | 620 | 590 | 530 | 480 | – | – | – | 950 | 840 | 780 | 770 | 690 | 640 | |

| N | 1 | 2520 | 2240 | 2060 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | – | – | – |

| 2 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | – | – | – | |

| 3 | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | – | – | – | – | – | – | |

| 4 | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | – | – | – | – | – | – | |

| H | 1 | 600 | 500 | 370 | 470 | 360 | 280 | – | – | – | 550 | 460 | 370 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Insert Selection

| Material Group | Light | General | Heavy | |||

| (Light geometry) | (Strong geometry) | |||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .LD.. | KC522M | .LD.. | KCPK30 | .LD.. | KCPK30 |

| P3–P4 | .LD.. | KC522M | .LD.. | KCPK30 | .LD.. | KCPK30 |

| P5–P6 | .LD.. | KCPK30 | .LD.. | KCPM20 | – | – |

| M1–M2 | .LD.. | KC522M | .LD.. | KC725M | – | – |

| M3 | .LD.. | KC522M | .LD.. | KC725M | – | – |

| K1–K2 | .LN.. | KC510M | .LD.. | KCPK30 | – | – |

| K3 | .LN.. | KC510M | .LD.. | KCPK30 | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .LD.. | KC522M | .LD.. | KC725M | – | – |

| S3 | .LD.. | KC725M | .LD.. | KC725M | – | – |

| S4 | .LD.. | KC522M | .LD.. | KC725M | – | – |

| H1 | .LN.. | KC510M | .LN.. | KC510M | – | – |

I have read and accepted the Terms & Conditions of use