Produkt ähnlich wie:

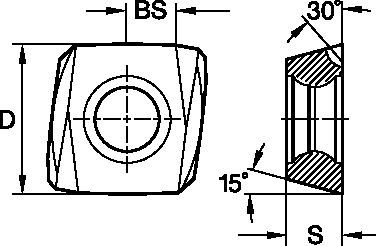

Fix-Perfect™ Cast Iron Finisher • Wiper Carbide Insert • MDHX-ZDER-GD4W • Semi-Finishing

Face milling insert with four cutting edges, precision ground.

Material Nummer1956732

ISO Katalog NummerMDHX1004ZDERGD4WASI Katalog NummerMDHX1004ZDERGD4W

- K Gusseisen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 1956732 |

| ISO Katalog Nummer | MDHX1004ZDERGD4W |

| ASI Katalog Nummer | MDHX1004ZDERGD4W |

| Sorte | KC520M |

Werkstoffe

- Gusseisen

Grades

KC520M

TiAlN-beschichtetes Hartmetall (PVD) KC520M ist eine Hartmetallsorte, die speziell für die allgemeine Bearbeitung von Kugelgraphitguss entwickelt wurde. Diese Sorte kann mit oder ohne Kühlmittel verwendet werden.

Features and benefits

- High-precision ground insert for superior surface finish and flatness.

- Milling insert for cast iron and compacted graphite iron (CGI) machining.

- Honed wiper cutting edge.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

Empfohlene Startwerte für Vorschübe [mm]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..GD4W | 0,23 | 0,84 | 1,41 | 0,17 | 0,60 | 1,01 | 0,13 | 0,45 | 0,75 | 0,11 | 0,39 | 0,66 | 0,10 | 0,36 | 0,60 | .F..GD4W |

| .E..GD4W | 0,26 | 0,93 | 1,67 | 0,19 | 0,67 | 1,19 | 0,14 | 0,50 | 0,88 | 0,12 | 0,44 | 0,77 | 0,11 | 0,40 | 0,70 | .E..GD4W |

| .E..GD | 0,26 | 1,03 | 1,90 | 0,19 | 0,74 | 1,35 | 0,14 | 0,55 | 1,00 | 0,12 | 0,48 | 0,87 | 0,11 | 0,44 | 0,80 | .E..GD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..GD4W | 0,23 | 0,84 | 1,41 | 0,17 | 0,60 | 1,01 | 0,13 | 0,45 | 0,75 | 0,11 | 0,39 | 0,66 | 0,10 | 0,36 | 0,60 | .F..GD4W |

| .E..GD4W | 0,26 | 0,93 | 1,67 | 0,19 | 0,67 | 1,19 | 0,14 | 0,50 | 0,88 | 0,12 | 0,44 | 0,77 | 0,11 | 0,40 | 0,70 | .E..GD4W |

| .E..GD | 0,26 | 1,03 | 1,90 | 0,19 | 0,74 | 1,35 | 0,14 | 0,55 | 1,00 | 0,12 | 0,48 | 0,87 | 0,11 | 0,44 | 0,80 | .E..GD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Recommended Starting Feeds [I.P.T.]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..GD4W | .004 | .005 | .007 | .003 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | .F..GD4W |

| .E..GD4W | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD4W |

| .E..GD | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..GD4W | .004 | .005 | .007 | .003 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | .F..GD4W |

| .E..GD4W | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD4W |

| .E..GD | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Speeds

Empfohlene Startwerte für Schnittgeschwindigkeit [m/Min]

| Werkstoffgruppe | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 155 | 145 | 135 | 325 | 295 | 260 | 275 | 235 | 195 |

| 2 | 135 | 130 | 120 | 255 | 225 | 215 | 220 | 180 | 160 | |

| 3 | 120 | 105 | 95 | 215 | 190 | 170 | 185 | 150 | 130 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Werkstoffgruppe | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 155 | 145 | 135 | 325 | 295 | 260 | 275 | 235 | 195 |

| 2 | 135 | 130 | 120 | 255 | 225 | 215 | 220 | 180 | 160 | |

| 3 | 120 | 105 | 95 | 215 | 190 | 170 | 185 | 150 | 130 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 910 | 770 | 640 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 720 | 590 | 520 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 600 | 500 | 420 | |

| N | 1–2 | 1980 | 1860 | 1770 | – | – | – | – | – | – |

| 3 | 1620 | 1440 | 1260 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Werkstoffgruppe | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 910 | 770 | 640 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 720 | 590 | 520 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 600 | 500 | 420 | |

| N | 1–2 | 1980 | 1860 | 1770 | – | – | – | – | – | – |

| 3 | 1620 | 1440 | 1260 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Insert Selection

Auswahlhilfe für Wendeschneidplatten

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | ||||

| Verschleiß- festigkeit |  | Zähigkeit | ||||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| K3 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| (Leicht schneidende Geometrie) | (Stabile Geometrie) | |||||

| Verschleiß- festigkeit |  | Zähigkeit | ||||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| K3 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data