Produkt ähnlich wie:

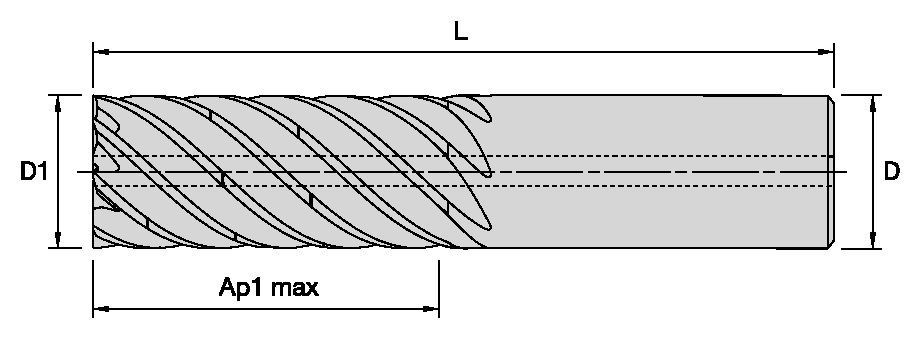

HARVI™ IV • Square End • 8 Flutes • Internal Coolant • Chipbreaker • Plain Shank • Inch

HARVI™ IV Eight Flute End Mill for Roughing and Finishing

Covering the Broadest Range of Applications and Materials

Material Nummer7102839

ISO Katalog NummerHA4R8SE0375R100HADANSI Katalog NummerHA4R8SE0375R100HAD

- P Stahl

- M Rostfreier Stahl

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

Trochoidal Milling

100665610

107038547

Spiralförmiges Interpolieren

Schräg-Eintauchfräsen Ins Volle

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Auskammern

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 7102839 |

| ISO Katalog Nummer | HA4R8SE0375R100HAD |

| ANSI Katalog Nummer | HA4R8SE0375R100HAD |

| Sorte | KCSM15A |

| Aufnahmeart Maschinenseite | Straight-Cylindrical |

| [D1] Effektiver Schneidendurchmesser | 9.525 mm |

| [D1] Effektiver Schneidendurchmesser | 0.375 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 9.525 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.375 in |

| [AP1MAX] 1. maximale Schnitttiefe | 25.4 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 1 in |

| [L3] Nutzbare Länge | 29.718 mm |

| [L3] Nutzbare Länge | 1.17 in |

| [L] Gesamtlänge | 76.2 mm |

| [L] Gesamtlänge | 3 in |

| [Z] Anzahl der Spannuten | 8 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

Uses and application

Trochoidal Milling

100665610

107038547

Spiralförmiges Interpolieren

Schräg-Eintauchfräsen Ins Volle

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Auskammern

Features and benefits

- Single tool for roughing and finishing to reduce tool setups.

- Proprietary core and flute design with optimum flute spacing for perfect chip formation and highest tool rigidity.

- Developed for highest productivity in titanium, high-temperature alloys, and stainless steels.

- With chip breakers for optimized chip evacuation.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Anwendungsdaten

| Adjustment factors for speed (Vc) and feed (Fz) • METRIC | |||||||

| Maximum cutting width (Ae) for given cutting depth (Ap) | |||||||

| Ap | ≤.125 x D1 | >.125xD1 ≤ .5xD1 | >.5xD1 ≤ 1xD1 | >1xD1 ≤ 2xD1 | >2xD1 ≤ 3xD1 | >3xD1 ≤ 4xD1 | >4 x D1 |

| Max Ae | 100% x D1 | 50% x D1 x KAp | 40% x D1 x KAp | 30% x D1 x KAp | 20% x D1 x KAp | 15% x D1 x KAp | 10% x D1 x KAp |

| Note: KAp value is given on the Speed and Feed table, according to the type of workpiece material selected. | |||||||

| Adjustment factors for speed (Vc) and feed (Fz) • METRIC | ||||||||||

| Ae/D1 | ≤2% | >2% ≤ 5% | >5 ≤ 7.5% | >7.5% ≤ 10% | >10% ≤ 15% | >15% ≤ 20% | >20% ≤ 30% | >30% ≤ 40% | >40% ≤ 50% | >50% ≤ 100% |

| Kv | 3 | 2.5 | 1.9 | 1.4 | 1.35 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| KFz | 3.28 | 2.3 | 1.95 | 1.7 | 1.5 | 1.25 | 1.09 | 1.02 | 1 | 1 |

| Note: Identify the radial engagement per percentage of the tool diameter (Ae/D1). That column will give you the factor to multiply the Base SMF and Base IPT on the Speed and Feed original table Kv = Factor to multiply the Speed by KFz = Factor to multiply the Feed by | ||||||||||

| To calculate application specific cutting data, please use KAp, Kv, and Kfz from tables above for adaption of cutting speeds and feeds respectively: Maximum Ae=(Ap1Max/D1) * KAp * D1 Vc new = Vc * Kv IPT new = IPT * KFz | Sample Calculation Material: S4 D1: 25 mm Ap: 2xD1 Max Ae: 30% x KAp x D1 --- 30% * 0.7 * D1 = 21%xD1 SFM: Base x Kv --- 45 * 1.2 = 54 IPT: Base x KFz --- 0.081 * 1.09 = 0.088 | Final cutting data recommendation: Max Ae = 0.3 * 0.7 * 25 = 5.25 mm Vc new = 45 * 1.2 = 54 m/min IPT new = 0.081 * 1.09 = 0.088 mm/th | ||||||||

| Table for Feed and Speed Calculation with Adjustment Factor • METRIC | ||||||||

| Schulterfräsen (A) | KCSM15A | Empfohlener Vorschub pro Zahn (fz = mm/Zahn) zum Eckfräaen mit ae/D=10% | |||||

| Werkstoffgruppe | Max Ae Factor (KAp) | Schnittgeschwindigkeit | 10 | 12 | 16 | 20 | 25 | |

| P | 3 | 1 | 130 | 0.049 | 0.055 | 0.067 | 0.080 | 0.095 |

| 4 | 1 | 100 | 0.044 | 0.049 | 0.059 | 0.069 | 0.081 | |

| 5 | 0.8 | 65 | 0.038 | 0.043 | 0.053 | 0.063 | 0.076 | |

| 6 | 0.7 | 50 | 0.032 | 0.036 | 0.043 | 0.050 | 0.060 | |

| M | 1 | 1 | 80 | 0.049 | 0.055 | 0.067 | 0.080 | 0.095 |

| 2 | 0.8 | 60 | 0.038 | 0.043 | 0.053 | 0.063 | 0.076 | |

| 3 | 0.8 | 60 | 0.032 | 0.036 | 0.043 | 0.050 | 0.060 | |

| S | 1 | 0.5 | 50 | 0.049 | 0.055 | 0.067 | 0.080 | 0.095 |

| 2 | 0.5 | 30 | 0.038 | 0.043 | 0.053 | 0.063 | 0.076 | |

| 3 | 0.5 | 25 | 0.026 | 0.030 | 0.036 | 0.043 | 0.051 | |

| 4 | 0.7 | 45 | 0.041 | 0.051 | 0.061 | 0.069 | 0.081 | |

| H | 1 | 0.8 | 80 | 0.044 | 0.049 | 0.059 | 0.069 | 0.081 |

| 2 | 0.5 | 70 | 0.037 | 0.041 | 0.050 | 0.059 | 0.070 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on | ||||||||

| Adjustment factors for speed (Vc) and feed (Fz) • INCH | ||||||||||

| Ae/D1 | ≤2% | >2% ≤ 5% | >5 ≤ 7.5% | >7.5% ≤ 10% | >10% ≤ 15% | >15% ≤ 20% | >20% ≤ 30% | >30% ≤ 40% | >40% ≤ 50% | >50% ≤ 100% |

| Kv | 3 | 2.5 | 1.9 | 1.4 | 1.35 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| KFz | 3.28 | 2.3 | 1.95 | 1.7 | 1.5 | 1.25 | 1.09 | 1.02 | 1 | 1 |

| Note: Identify the radial engagement per percentage of the tool diameter (Ae/D1). That column will give you the factor to multiply the Base SMF and Base IPT on the Speed and Feed original table Kv = Factor to multiply the Speed by KFz = Factor to multiply the Feed by | ||||||||||

| To calculate application specific cutting data, please use KAp, Kv, and Kfz from tables above for adaption of cutting speeds and feeds respectively: Maximum Ae=(Ap1Max/D1) * KAp * D1 Vc new = Vc * Kv IPT new = IPT * KFz | Sample Calculation Material: S4 D1: 25 mm Ap: 2xD1 Max Ae: 30% x KAp x D1 --- 30% * 0.7 * D1 = 21%xD1 SFM: Base x Kv --- 45 * 1.2 = 54 IPT: Base x KFz --- 0.081 * 1.09 = 0.088 | Final cutting data recommendation: Max Ae = 0.3 * 0.7 * 25 = 5.25 mm Vc new = 45 * 1.2 = 54 m/min IPT new = 0.081 * 1.09 = 0.088 mm/th | ||||||||

| Table for Feed and Speed Calculation with Adjustment Factor • INCH | |||||||||

| Schulterfräsen (A) | KCSM15A | Recommended feed per tooth (fz=IPT) for side milling | ||||||

| frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||

| Werkstoffgruppe | Max Ae Factor (KAp) | Schnittgeschwindigkeit | dec. | 0.375 | 0.500 | 0.625 | 0.750 | 1 | |

| P | 3 | 1 | 420 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.003 | 0.0037 |

| 4 | 1 | 320 | IPT | 0.0016 | 0.0021 | 0.0024 | 0.0026 | 0.0031 | |

| 5 | 0.8 | 210 | IPT | 0.0014 | 0.0018 | 0.0022 | 0.0024 | 0.0029 | |

| 6 | 0.7 | 160 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0019 | 0.0022 | |

| M | 1 | 1 | 275 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.003 | 0.0037 |

| 2 | 0.8 | 200 | IPT | 0.0014 | 0.0018 | 0.0022 | 0.0024 | 0.0029 | |

| 3 | 0.8 | 200 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0019 | 0.0022 | |

| S | 1 | 0.5 | 160 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.003 | 0.0037 |

| 2 | 0.5 | 100 | IPT | 0.0014 | 0.0018 | 0.0022 | 0.0024 | 0.0029 | |

| 3 | 0.5 | 80 | IPT | 0.001 | 0.0013 | 0.0014 | 0.0016 | 0.002 | |

| 4 | 0.7 | 160 | IPT | 0.0016 | 0.002 | 0.0024 | 0.0027 | 0.0032 | |

| H | 1 | 0.8 | 260 | IPT | 0.0016 | 0.0021 | 0.0024 | 0.0026 | 0.0031 |

| 2 | 0.5 | 230 | IPT | 0.0014 | 0.0018 | 0.002 | 0.0022 | 0.0026 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on | |||||||||

| Adjustment factors for speed (Vc) and feed (Fz) • INCH | |||||||

| Maximum cutting width (Ae) for given cutting depth (Ap) | |||||||

| Ap | ≤.125 x D1 | >.125xD1 ≤ .5xD1 | >.5xD1 ≤ 1xD1 | >1xD1 ≤ 2xD1 | >2xD1 ≤ 3xD1 | >3xD1 ≤ 4xD1 | >4 x D1 |

| Max Ae | 100% x D1 | 50% x D1 x KAp | 40% x D1 x KAp | 30% x D1 x KAp | 20% x D1 x KAp | 15% x D1 x KAp | 10% x D1 x KAp |

| Note: KAp value is given on the Speed and Feed table, according to the type of workpiece material selected. | |||||||

TechnicalInfo

| Angle of engagement (phi°) relative to cutting width (Ae) |  | |||||||||

| ae | 2% | 5% | 7.50% | 10% | 15% | 20% | 30% | 40% | 50% | 100% |

| phi - angle of engagement | 16.26 | 25.84 | 31.79 | 36.87 | 45.57 | 53.13 | 66.42 | 78.46 | 90 | 180 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data