Produkt ähnlich wie:

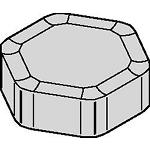

HexaCut 30° • Cast Iron • Shell Mills • Roughing • Right Hand • Inch

Shell Mills • Roughing

Material Nummer2430924

ISO Katalog NummerK500B123RF60HN09CANSI Katalog NummerK500B123RF60HN09C

- P Stahl

- K Gusseisen

- N NE-Metalle

- H Gehärtete Werkstoffe

Planfräsen

Fräsen – Eckfräsen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

| Material Nummer | 2430924 |

| ISO Katalog Nummer | K500B123RF60HN09C |

| ANSI Katalog Nummer | K500B123RF60HN09C |

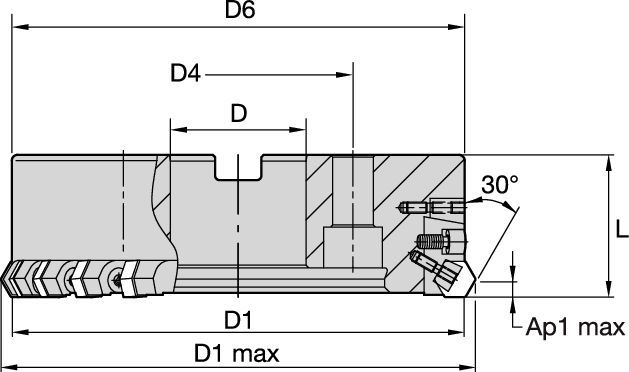

| [D1] Effektiver Schneidendurchmesser | 127 mm |

| [D1] Effektiver Schneidendurchmesser | 5 in |

| [D1MAX] Schnittdurchmesser max. | 135.636 mm |

| [D1MAX] Schnittdurchmesser max. | 5.34 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 38.1 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 1.5 in |

| [D6] Nabendurchmesser | 127 mm |

| [D6] Nabendurchmesser | 5 in |

| [L] Gesamtlänge | 60.452 mm |

| [L] Gesamtlänge | 2.38 in |

| [AP1MAX] 1. maximale Schnitttiefe | 8 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.315 in |

| Anzahl der Schneidkörper | 15 |

| Anzahl einstellbarer Wendeschneidplatten | 3 |

| Gewicht Pfund | 10 |

| Max. Drehzahl | 3000 |

Werkstoffe

- Stahl

- Gusseisen

- NE-Metalle

- Gehärtete Werkstoffe

Uses and application

Planfräsen

Fräsen – Eckfräsen

Features and benefits

- CGI-Fräslösung

- Fräser in Monoblock-Ausführung

- Hervorragende Oberflächengüte

- Hohe Vorschübe

- Zwölf Schneidkanten

Feeds

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| ...MCI | .008 | .021 | .037 | .006 | .015 | .027 | .004 | .011 | .020 | .004 | .010 | .017 | .004 | .009 | .016 | ...MCI |

| .E..LE | .008 | .021 | .037 | .006 | .015 | .027 | .004 | .011 | .020 | .004 | .010 | .017 | .004 | .009 | .016 | .E..LE |

| ...MR | .011 | .023 | .040 | .008 | .016 | .029 | .006 | .012 | .021 | .005 | .011 | .019 | .005 | .010 | .017 | ...MR |

| .S..GE | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .013 | .020 | .005 | .012 | .018 | .S..GE |

| ...SN | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .013 | .020 | .005 | .012 | .018 | ...SN |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Speeds

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KCK15 | KCPK30 | KC514M | KC524M | KC907M | KC914M | KC917M | KC924M | KY3500 | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1660 | 1510 | 1340 | 1160 | 1050 | 940 | 1570 | 1150 | 830 | 1470 | 1050 | 750 | 1600 | 1190 | 1000 | 1370 | 1180 | 980 | 1180 | 980 | 780 | 1150 | 900 | 660 | 3170 | 2880 | 2560 |

| 2 | 1310 | 1170 | 1090 | 920 | 830 | 760 | 1380 | 920 | 680 | 1280 | 820 | 620 | 1260 | 980 | 820 | 1180 | 980 | 820 | 980 | 780 | 660 | 900 | 720 | 580 | 2510 | 2240 | 2090 | |

| 3 | 1100 | 980 | 900 | 770 | 690 | 640 | 1100 | 850 | 660 | 980 | 730 | 520 | 980 | 820 | 660 | 980 | 820 | 660 | 780 | 660 | 520 | 720 | 580 | 460 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | (Stabile Geometrie) | ||||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..LE | KCK15 | ...MR | KCK15 | .S..GE | KCK15 |

| K3 | .E..LE | KCK15 | ...MR | KC524M | .S..GE | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data