Produkt ähnlich wie:

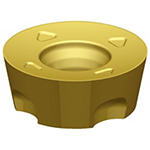

RPPT12-432-X4 • Präzisionsgepresst • 4 Schneidkanten • Für die Bearbeitung von Edelstahl und warmfesten Legierungen

Wendeschneidplatten

Material Nummer6201910

ISO Katalog NummerRPPT1204M0E432X4ANSI Katalog NummerRPPT1204M0E432X4

- P Stahl

- M Rostfreier Stahl

- S Hochwarmfeste Legierungen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 6201910 |

| ISO Katalog Nummer | RPPT1204M0E432X4 |

| ANSI Katalog Nummer | RPPT1204M0E432X4 |

| Sorte | KCSM40 |

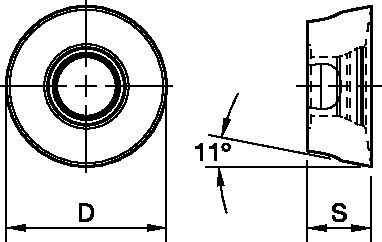

| [D] Wendeschneidplatten-Größe (Inkreis) | 12 mm |

| [D] Wendeschneidplatten-Größe (Inkreis) | 0.472 in |

| [S] Dicke der Wendeschneidplatte | 4.763 mm |

| [S] Dicke der Wendeschneidplatte | 0.1875 in |

| Mittlere Spandicke [HM] | 0.04 mm |

| Mittlere Spandicke [HM] | 0.0016 in |

| Wendeschneidplatte Anzahl der Schneidkanten | 4 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Hochwarmfeste Legierungen

Grades

KCSM40

Hartmetallschneidstoff mit neuartiger PVD-TiAlN/TiN-Beschichtung. Premium-Substrat mit neu entwickelter Binderzusammensetzung. KCSM40 ist eine Hochleistungssorte für Titan, Superlegierungen und nicht rostenden Stahl. Durch die hohe Wärmewechselbeständigkeit des Substrats ist dieser Schneidstoff ideal für die Nassbearbeitung geeignet. Erste Wahl für das Schruppen und bei schwierigen Schnittbedingungen.

Features and benefits

- First choice for roughing stainless steel and heat-resistant alloys

- Precision-pressed insert

- Four indexation positions: — Ap max: 6mm — Ap recommended: ≤3,5mm

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

Bei einer axialen Schnitttiefe von 6,00 (ap)

| Schneidkörper– Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,12 | 0,16 | 0,22 | 0,08 | 0,12 | 0,16 | 0,06 | 0,09 | 0,12 | 0,05 | 0,08 | 0,10 | 0,05 | 0,07 | 0,10 | 701–X4 |

| 432–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,23 | 0,41 | 0,66 | 0,17 | 0,30 | 0,47 | 0,13 | 0,22 | 0,35 | 0,11 | 0,19 | 0,31 | 0,10 | 0,18 | 0,28 | 442–X4 |

| GD–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,23 | 0,41 | 0,66 | 0,17 | 0,30 | 0,47 | 0,13 | 0,22 | 0,35 | 0,11 | 0,19 | 0,31 | 0,10 | 0,18 | 0,28 | T–X4 |

Bei einer axialen Schnitttiefe von 3,00 (ap)

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Bei einer axialen Schnitttiefe von 2,50 (ap)

| Schneidkörper– Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,13 | 0,19 | 0,25 | 0,10 | 0,14 | 0,18 | 0,07 | 0,10 | 0,14 | 0,06 | 0,09 | 0,12 | 0,06 | 0,08 | 0,11 | 701–X4 |

| 432–X5 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,16 | 0,49 | 0,93 | 0,12 | 0,35 | 0,66 | 0,09 | 0,26 | 0,49 | 0,08 | 0,23 | 0,43 | 0,07 | 0,21 | 0,39 | 442–X4 |

| GD–X5 | 0,16 | 0,54 | 0,99 | 0,12 | 0,39 | 0,70 | 0,09 | 0,29 | 0,52 | 0,08 | 0,25 | 0,45 | 0,07 | 0,23 | 0,42 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,27 | 0,68 | 1,10 | 0,19 | 0,49 | 0,78 | 0,14 | 0,36 | 0,58 | 0,13 | 0,32 | 0,50 | 0,12 | 0,29 | 0,46 | T–X4 |

Bei einer axialen Schnitttiefe von 1,50 (ap)

| Schneidkörper– Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,17 | 0,24 | 0,33 | 0,13 | 0,18 | 0,24 | 0,09 | 0,13 | 0,18 | 0,08 | 0,12 | 0,16 | 0,08 | 0,11 | 0,14 | 701–X4 |

| 432–X5 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 432–X5 |

| 432–X8 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 432–X8 |

| 442–X5 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X5 |

| 442–X8 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X8 |

| 442–X4 | 0,21 | 0,64 | 1,23 | 0,15 | 0,46 | 0,87 | 0,11 | 0,34 | 0,65 | 0,10 | 0,30 | 0,56 | 0,09 | 0,27 | 0,51 | 442–X4 |

| GD–X5 | 0,21 | 0,71 | 1,31 | 0,15 | 0,51 | 0,93 | 0,11 | 0,38 | 0,68 | 0,10 | 0,33 | 0,60 | 0,09 | 0,30 | 0,54 | GD–X5 |

| GD–X8 | 0,21 | 0,71 | 1,31 | 0,15 | 0,51 | 0,93 | 0,11 | 0,38 | 0,68 | 0,10 | 0,33 | 0,60 | 0,09 | 0,30 | 0,54 | GD–X8 |

| T–X4 | 0,35 | 0,90 | 1,47 | 0,25 | 0,64 | 1,03 | 0,19 | 0,47 | 0,76 | 0,17 | 0,41 | 0,66 | 0,15 | 0,38 | 0,60 | T–X4 |

| Schneidkörper– Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | 0,14 | 0,20 | 0,27 | 0,10 | 0,14 | 0,20 | 0,08 | 0,11 | 0,15 | 0,07 | 0,09 | 0,13 | 0,06 | 0,09 | 0,12 | 701–X4 |

| 432–X5 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | 0,17 | 0,52 | 1,00 | 0,12 | 0,37 | 0,71 | 0,09 | 0,28 | 0,53 | 0,08 | 0,24 | 0,46 | 0,07 | 0,22 | 0,42 | 442–X4 |

| GD–X5 | 0,17 | 0,58 | 1,06 | 0,12 | 0,41 | 0,75 | 0,09 | 0,31 | 0,56 | 0,08 | 0,27 | 0,48 | 0,07 | 0,25 | 0,44 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | 0,29 | 0,73 | 1,18 | 0,21 | 0,52 | 0,84 | 0,15 | 0,39 | 0,62 | 0,13 | 0,34 | 0,54 | 0,12 | 0,31 | 0,49 | T–X4 |

At .236 Axial Depth of Cut (ap)

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

At .118 Axial Depth of Cut (ap)

| Schneidkörper– Geometrie | Programmierter Vorschub pro Zahn (fz) als % der radialen Schnitttiefe (ae) | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .005 | .008 | .011 | .003 | .006 | .008 | .002 | .004 | .006 | .002 | .004 | .005 | .002 | .004 | .005 | 701–X4 |

| 432–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .007 | .021 | .037 | .005 | .015 | .027 | .004 | .011 | .020 | .003 | .010 | .017 | .003 | .009 | .016 | 442–X4 |

| GD–X5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .012 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | T–X4 |

At .098 Axial Depth of Cut (ap)

| Schneidkörper– Geometrie | Programmierter Vorschub pro Zahn (fz) als % der radialen Schnitttiefe (ae) | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .005 | .009 | .013 | .004 | .007 | .009 | .003 | .005 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | 701–X4 |

| 432–X5 | .006 | .019 | .037 | .005 | .014 | .027 | .003 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | .006 | .019 | .037 | .005 | .014 | .027 | .003 | .010 | .020 | .003 | .009 | .017 | .003 | .008 | .016 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .008 | .024 | .043 | .006 | .017 | .031 | .004 | .013 | .023 | .004 | .011 | .020 | .003 | .010 | .018 | 442–X4 |

| GD–X5 | .006 | .022 | .040 | .005 | .016 | .028 | .003 | .012 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .012 | .020 | .005 | .011 | .018 | T–X4 |

At .059 Axial Depth of Cut (ap)

| Schneidkörper– Geometrie | Programmierter Vorschub pro Zahn (fz) als % der radialen Schnitttiefe (ae) | Schneidkörper– Geometrie | ||||||||||||||

| – | 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| 701–X4 | .007 | .012 | .017 | .005 | .009 | .012 | .004 | .007 | .009 | .003 | .006 | .008 | .003 | .005 | .007 | 701–X4 |

| 432–X5 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 432–X5 |

| 432–X8 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 432–X8 |

| 442–X5 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 442–X5 |

| 442–X8 | .008 | .026 | .049 | .006 | .018 | .035 | .005 | .014 | .026 | .004 | .012 | .022 | .004 | .011 | .021 | 442–X8 |

| 442–X4 | .011 | .032 | .058 | .008 | .023 | .041 | .006 | .017 | .030 | .005 | .015 | .026 | .005 | .014 | .024 | 442–X4 |

| GD–X5 | .008 | .028 | .053 | .006 | .020 | .037 | .005 | .015 | .027 | .004 | .013 | .024 | .004 | .012 | .022 | GD–X5 |

| GD–X8 | .008 | .028 | .053 | .006 | .020 | .037 | .005 | .015 | .027 | .004 | .013 | .024 | .004 | .012 | .022 | GD–X8 |

| T–X4 | .014 | .035 | .058 | .010 | .025 | .041 | .007 | .019 | .030 | .006 | .016 | .026 | .006 | .015 | .024 | T–X4 |

| Schneidkörper– Geometrie | Programmierter Vorschub pro Zahn (fz) als % der radialen Schnitttiefe (ae) | Schneidkörper– Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| 701–X4 | .006 | .010 | .014 | .004 | .007 | .010 | .003 | .005 | .007 | .003 | .005 | .006 | .002 | .004 | .006 | 701–X4 |

| 432–X5 | .007 | .021 | .040 | .005 | .015 | .028 | .004 | .011 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | 432–X5 |

| 432–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 432–X8 |

| 442–X5 | .007 | .021 | .040 | .005 | .015 | .028 | .004 | .011 | .021 | .003 | .010 | .018 | .003 | .009 | .017 | 442–X5 |

| 442–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 442–X8 |

| 442–X4 | .009 | .026 | .046 | .006 | .019 | .033 | .005 | .014 | .024 | .004 | .012 | .021 | .004 | .011 | .019 | 442–X4 |

| GD–X5 | .007 | .023 | .042 | .005 | .017 | .030 | .004 | .012 | .022 | .003 | .011 | .019 | .003 | .010 | .018 | GD–X5 |

| GD–X8 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | GD–X8 |

| T–X4 | .011 | .029 | .046 | .008 | .020 | .033 | .006 | .015 | .024 | .005 | .013 | .021 | .005 | .012 | .019 | T–X4 |

Speeds

Empfohlene Startwerte für Schnittgeschwindigkeiten [m/min]

| Werkstoffgruppe | GH1 | X700 | KCM40 | SP6519 | X500 | MP91M | SC6525 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 130 | 213 | 295 | 130 | 200 | 270 | 140 | 243 | 345 | 140 | 255 | 370 |

| 2 | – | – | – | – | – | – | – | – | – | 115 | 188 | 260 | 115 | 178 | 240 | 120 | 213 | 305 | 120 | 223 | 325 | |

| 3 | – | – | – | – | – | – | 100 | 170 | 240 | 100 | 165 | 230 | 100 | 155 | 210 | 105 | 188 | 270 | 105 | 198 | 290 | |

| 4 | – | – | – | – | – | – | 75 | 128 | 180 | 75 | 125 | 175 | 75 | 118 | 160 | 80 | 143 | 205 | 80 | 145 | 210 | |

| 5 | – | – | – | 70 | 103 | 135 | – | – | – | 70 | 105 | 140 | 70 | 100 | 130 | – | – | – | 80 | 120 | 160 | |

| 6 | – | – | – | 50 | 83 | 115 | – | – | – | 50 | 85 | 120 | 50 | 80 | 110 | – | – | – | 60 | 100 | 140 | |

| M | 1 | – | – | – | 115 | 188 | 260 | 115 | 188 | 260 | 115 | 193 | 270 | 115 | 183 | 250 | – | – | – | 120 | 205 | 290 |

| 2 | – | – | – | 105 | 168 | 230 | 100 | 165 | 230 | 105 | 170 | 235 | 100 | 160 | 220 | – | – | – | 110 | 185 | 260 | |

| 3 | – | – | – | 85 | 138 | 190 | 50 | 83 | 115 | 85 | 140 | 195 | 80 | 130 | 180 | – | – | – | 90 | 150 | 210 | |

| K | 1 | 135 | 213 | 290 | – | – | – | – | – | – | 140 | 218 | 295 | 120 | 200 | 280 | 145 | 255 | 365 | 145 | 268 | 390 |

| 2 | 120 | 183 | 245 | – | – | – | – | – | – | 110 | 175 | 240 | 105 | 155 | 205 | 115 | 200 | 285 | 115 | 210 | 305 | |

| 3 | 115 | 158 | 200 | – | – | – | – | – | – | 100 | 160 | 220 | 95 | 133 | 170 | 105 | 183 | 260 | – | – | – | |

| N | 1–2 | 400 | 1725 | 3050 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 295 | 1368 | 2440 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 23 | 38 | 52 | 23 | 38 | 52 | 23 | 39 | 55 | 23 | 36 | 48 | – | – | – | – | – | – |

| 2 | – | – | – | 22 | 34 | 46 | 22 | 34 | 46 | 22 | 35 | 48 | 21 | 33 | 44 | – | – | – | – | – | – | |

| 3 | – | – | – | 25 | 39 | 53 | 25 | 39 | 53 | 25 | 40 | 55 | 24 | 38 | 51 | – | – | – | – | – | – | |

| 4 | – | – | – | 36 | 56 | 75 | 36 | 56 | 75 | 36 | 58 | 79 | 35 | 54 | 73 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 78 | 105 | 50 | 80 | 110 |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | GH1 | X700 | KCM40 | SP6519 | X500 | MP91M | SC6525 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 426 | 697 | 459 | 426 | 656 | 886 | 459 | 795 | 1132 | 459 | 836 | 1214 |

| 2 | – | – | – | – | – | – | – | – | – | 377 | 615 | 394 | 377 | 582 | 787 | 394 | 697 | 1000 | 394 | 730 | 1066 | |

| 3 | – | – | – | – | – | – | 328 | 558 | 787 | 328 | 541 | 344 | 328 | 508 | 689 | 344 | 615 | 886 | 344 | 648 | 951 | |

| 4 | – | – | – | – | – | – | 246 | 418 | 590 | 246 | 410 | 262 | 246 | 385 | 525 | 262 | 467 | 672 | 262 | 476 | 689 | |

| 5 | – | – | – | 230 | 338 | 443 | – | – | – | 246 | 410 | 230 | 230 | 328 | 426 | – | – | – | 262 | 394 | 525 | |

| 6 | – | – | – | 164 | 272 | 377 | – | – | – | 230 | 344 | 164 | 164 | 262 | 361 | – | – | – | 197 | 328 | 459 | |

| M | 1 | – | – | – | 377 | 615 | 853 | 377 | 615 | 853 | 377 | 631 | 394 | 377 | 599 | 820 | – | – | – | 394 | 672 | 951 |

| 2 | – | – | – | 344 | 549 | 754 | 328 | 541 | 754 | 344 | 558 | 361 | 328 | 525 | 722 | – | – | – | 361 | 607 | 853 | |

| 3 | – | – | – | 279 | 451 | 623 | 164 | 271 | 377 | 279 | 459 | 295 | 262 | 426 | 590 | – | – | – | 295 | 492 | 689 | |

| K | 1 | 443 | 697 | 951 | – | – | – | – | – | – | 459 | 713 | 476 | 394 | 656 | 918 | 476 | 836 | 1197 | 476 | 877 | 1279 |

| 2 | 394 | 599 | 804 | – | – | – | – | – | – | 361 | 574 | 377 | 344 | 508 | 672 | 377 | 656 | 935 | 377 | 689 | 1000 | |

| 3 | 377 | 517 | 656 | – | – | – | – | – | – | 328 | 525 | 344 | 312 | 435 | 558 | 344 | 599 | 853 | – | – | – | |

| N | 1–2 | 1312 | 5658 | 10004 | – | – | – | – | – | – | – | – | 1312 | – | – | – | – | – | – | – | – | – |

| 3 | 968 | 4485 | 8003 | – | – | – | – | – | – | – | – | 968 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 75 | 123 | 171 | 75 | 123 | 171 | 75 | 128 | 79 | 75 | 116 | 157 | – | – | – | – | – | – |

| 2 | – | – | – | 72 | 112 | 151 | 72 | 112 | 151 | 72 | 115 | 75 | 69 | 107 | 144 | – | – | – | – | – | – | |

| 3 | – | – | – | 82 | 128 | 174 | 82 | 128 | 174 | 82 | 131 | 85 | 79 | 123 | 167 | – | – | – | – | – | – | |

| 4 | – | – | – | 118 | 182 | 246 | 118 | 182 | 246 | 118 | 189 | 121 | 115 | 177 | 239 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | 164 | – | – | – | 164 | 254 | 344 | 164 | 262 | 361 |

Insert Selection

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | 442-X8 | SC6525 | 432-X5 | SC6525 | GD-X5 | KCM40 |

| P3–P4 | 432-X8 | SP6519 | 432-X5 | SP6519 | GD-X5 | KCM40 |

| P5–P6 | 432-X8 | SP6519 | T-X4 | SP6519 | T-X4 | X500 |

| M1–M2 | 442-X8 | SC6525 | 432-X5 | SC6525 | GD-X5 | KCM40 |

| M3 | 432-X8 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| K1–K2 | T-X4 | MP91M | T-X4 | MP91M | T-X4 | MP91M |

| K3 | T-X4 | MP91M | T-X4 | MP91M | T-X4 | MP91M |

| N1–N2 | 701-X4 | GH1 | 701-X4 | GH1 | 701-X4 | GH1 |

| N3 | 701-X4 | GH1 | 701-X4 | GH1 | 701-X4 | GH1 |

| S1–S2 | 442-X5 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| S3 | 442-X5 | SP6519 | GD-X5 | KCM40 | 442-X4 | X500 |

| S4 | 442-X5 | SP6519 | 442-X5 | X500 | 442-X4 | X500 |

| H1 | – | – | T-X4 | MP91M | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data