Product Similar To :

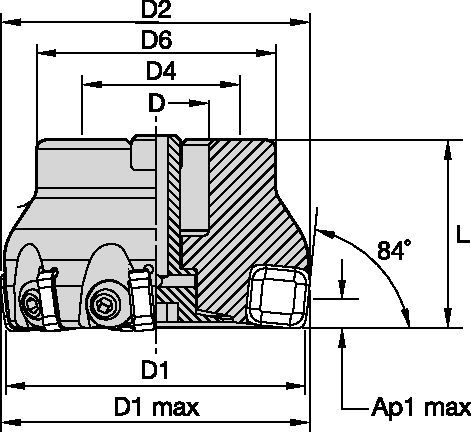

KSSR™ 84° • Shell Mill • Fine Pitch • Metric

Face Mill • Cast Iron Machining

Material Number2443937

ISO Catalog ID80A12RF84SN12BANSI Catalog ID80A12RF84SN12B

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Face Milling

Milling - Through Coolant

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 2443937 |

| ISO Catalog ID | 80A12RF84SN12B |

| ANSI Catalog ID | 80A12RF84SN12B |

| [D1] Effective Cutting Diameter | 80 mm |

| [D1] Effective Cutting Diameter | 3.1496 in |

| [D1MAX] Maximum Cutting Diameter | 82 mm |

| [D1MAX] Maximum Cutting Diameter | 3.2283 in |

| [D] Adapter / Shank / Bore Diameter | 27 mm |

| [D] Adapter / Shank / Bore Diameter | 1.063 in |

| [D2] Maximum Body Diameter | 80.42 mm |

| [D2] Maximum Body Diameter | 3.1661 in |

| [D6] Hub Diameter | 60 mm |

| [D6] Hub Diameter | 2.3622 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.9685 in |

| [AP1MAX] 1st Maximum Cutting Depth | 5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.1969 in |

| Number of Inserts | 12 |

| Weight Kilograms | 1.25 |

| Max RPM | 6000 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Face Milling

Milling - Through Coolant

Milling - Side and Face

Features and benefits

- Milling cutters for cast iron and compacted graphite iron (CGI) machining.

- Perfect solution for any production with transfer lines.

- KSSR produces excellent surface finishes due to high axial and radial accuracy.

- High feed rate capability.

- Easy indexing through wedge clamping.

- Cutters come with coolant shower plate.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..LD | 0,18 | 0,46 | 0,82 | 0,13 | 0,33 | 0,59 | 0,10 | 0,25 | 0,44 | 0,09 | 0,22 | 0,39 | 0,08 | 0,20 | 0,35 | .E..LD |

| .S..GP | 0,20 | 0,50 | 0,90 | 0,14 | 0,36 | 0,65 | 0,11 | 0,27 | 0,48 | 0,09 | 0,24 | 0,42 | 0,09 | 0,22 | 0,39 | .S..GP |

| .S..HE | 0,18 | 0,51 | 0,95 | 0,13 | 0,37 | 0,69 | 0,10 | 0,28 | 0,51 | 0,09 | 0,24 | 0,45 | 0,08 | 0,22 | 0,41 | .S..HE |

| .A..SN | 0,24 | 0,59 | 0,95 | 0,17 | 0,43 | 0,69 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,45 | 0,10 | 0,26 | 0,41 | .A..SN |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KCK15 | KC514M | KC524M | KC907M | KC914M | KC917M | KY3500 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 505 | 460 | 410 | 480 | 350 | 255 | 450 | 320 | 230 | 490 | 365 | 305 | 420 | 360 | 300 | 360 | 300 | 240 | 965 | 880 | 780 |

| 2 | 400 | 355 | 330 | 420 | 280 | 205 | 390 | 250 | 190 | 385 | 300 | 250 | 360 | 300 | 250 | 300 | 240 | 200 | 765 | 685 | 635 | |

| 3 | 335 | 300 | 275 | 335 | 260 | 200 | 300 | 225 | 160 | 300 | 250 | 200 | 300 | 250 | 200 | 240 | 200 | 160 | 645 | 570 | 525 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | – | (Strong geometry) | ||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1 | – | – | – | – | – | – |

| P3 | – | – | – | – | – | – |

| P5 | – | – | – | – | – | – |

| M1 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1 | .E..LD | KCK15 | .S..GP | KCK15 | .A..SN | KY3500 |

| K3 | .E..LD | KCK20 | .S..GP | KCK20 | .S..HE | KCK20 |

| N1 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use