Produkt ähnlich wie:

KIPR - RP • Screw-On End Mills • Inch

Screw-On End Mills

Material Nummer3760369

ISO Katalog NummerKIPR100RP32M1203ANSI Katalog NummerKIPR100RP32M1203

- P Stahl

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

- .caption

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Kugelkopf / Vollradius

Umfangfräsen/Schulterfräsen: Kugelkopf / Vollradius

3D-Profilfräsen/Kopierfräsen

Schaft – Aufschraubbar

Auskammern

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

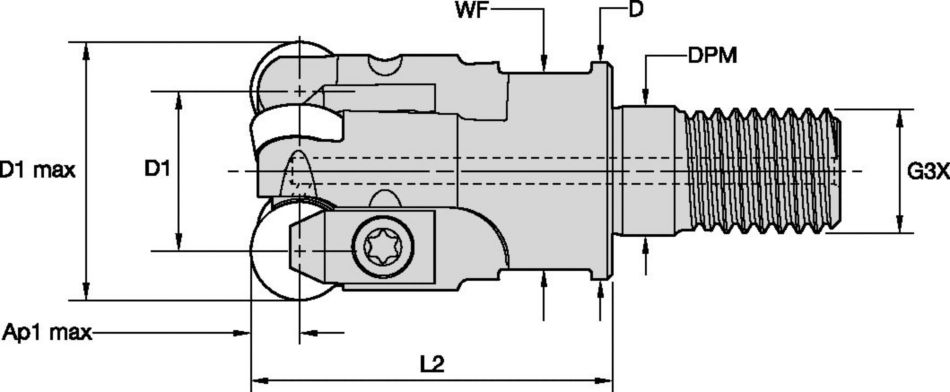

| Material Nummer | 3760369 |

| ISO Katalog Nummer | KIPR100RP32M1203 |

| ANSI Katalog Nummer | KIPR100RP32M1203 |

| [D1MAX] Schnittdurchmesser max. | 25.4 mm |

| [D1MAX] Schnittdurchmesser max. | 1 in |

| [D1] Effektiver Schneidendurchmesser | 15.9 mm |

| [D1] Effektiver Schneidendurchmesser | 0.625 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 21 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.8268 in |

| [DPM] Führungsdurchmesser Maschinenseite | 12.5 mm |

| [DPM] Führungsdurchmesser Maschinenseite | 0.4921 in |

| [G3X] Verbindungsgewinde Größe extern | M12 |

| [L2] Kopflänge | 31.75 mm |

| [L2] Kopflänge | 1.25 in |

| [WF] Flächenbreite | 18 mm |

| [WF] Flächenbreite | 0.709 in |

| [AP1MAX] 1. maximale Schnitttiefe | 4.76 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.1875 in |

| Anzahl der Schneidkörper | 3 |

| Maximaler Eintauchwinkel | 8 |

| Max. Drehzahl | 20450 |

| Gewicht Pfund | 0.17 |

| Wendeschneidplatten-Größe | RP_32_ |

Werkstoffe

- Stahl

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

- .caption

Uses and application

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Kugelkopf / Vollradius

Umfangfräsen/Schulterfräsen: Kugelkopf / Vollradius

3D-Profilfräsen/Kopierfräsen

Schaft – Aufschraubbar

Auskammern

Features and benefits

- For machining high-temp alloys, PH stainless, stainless steels, and hardened materials.

- Excellent productivity through massive reduction of machining time.

- Face milling, pocketing, and ramping capabilities.

- Through-body coolant delivery for internal air supply only.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .005 | .007 | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | ..E |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .010 | .011 | .014 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .008 | .006 | .006 | .008 | ..E |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .006 | .008 | .004 | .004 | .006 | .004 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | ..E |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .007 | .008 | .010 | .005 | .006 | .008 | .005 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..E |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .005 | .007 | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | ..E |

| ..T | .007 | .008 | .010 | .005 | .006 | .008 | .004 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..T |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .006 | .008 | .004 | .004 | .006 | .004 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | ..E |

| ..T | .008 | .009 | .012 | .006 | .007 | .009 | .005 | .006 | .008 | .005 | .006 | .007 | .005 | .006 | .007 | ..T |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .010 | .011 | .014 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .008 | .006 | .006 | .008 | ..E |

| ..T | .014 | .017 | .021 | .010 | .012 | .016 | .009 | .011 | .014 | .008 | .010 | .013 | .008 | .010 | .012 | ..T |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .007 | .008 | .010 | .005 | .006 | .008 | .005 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..E |

| ..T | .010 | .012 | .015 | .008 | .009 | .011 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .009 | ..T |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .005 | .007 | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | ..E |

| ..T | .007 | .010 | .011 | .005 | .008 | .009 | .004 | .007 | .007 | .004 | .006 | .007 | .004 | .006 | .007 | ..T |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .006 | .008 | .004 | .004 | .006 | .004 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | ..E |

| ..T | .008 | .012 | .013 | .006 | .009 | .010 | .005 | .008 | .009 | .005 | .007 | .008 | .005 | .007 | .008 | ..T |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .010 | .011 | .014 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .008 | .006 | .006 | .008 | ..E |

| ..T | .014 | .022 | .024 | .010 | .016 | .018 | .009 | .014 | .015 | .008 | .013 | .014 | .008 | .013 | .014 | ..T |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .007 | .008 | .010 | .005 | .006 | .008 | .005 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..E |

| ..T | .010 | .016 | .017 | .008 | .012 | .013 | .007 | .010 | .011 | .006 | .010 | .010 | .006 | .009 | .010 | ..T |

Speeds

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KYHS10 | KYSM10 | KYSP30 | KYS30 | KY2100 | KY4300 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | 3960 | 3200 | 2380 | 3000 | 2400 | 1800 | 3000 | 2400 | 1800 | 3300 | 2670 | 1980 | – | – | – | |

| 6 | – | – | – | 3960 | 3200 | 2380 | 3000 | 2400 | 1800 | 3000 | 2400 | 1800 | 3300 | 2670 | 1980 | – | – | – | |

| M | 1 | – | – | – | 3960 | 3200 | 2380 | – | – | – | – | – | – | 3300 | 2670 | 1980 | – | – | – |

| 2 | – | – | – | 3740 | 3000 | – | – | – | – | – | – | – | 3120 | 2500 | – | – | – | – | |

| 3 | – | – | – | 2760 | 2400 | – | – | – | – | – | – | – | 2300 | 2000 | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 1680 | 1320 | 960 | 3490 | 2860 | 2220 | 2640 | 2160 | 1680 | 2640 | 2160 | 1680 | 2910 | 2380 | 1850 | – | – | – |

| 2 | 1680 | 1320 | 960 | 3490 | 2860 | 2220 | 2640 | 2160 | 1680 | 2640 | 2160 | 1680 | 2910 | 2380 | 1850 | 1400 | 1100 | 800 | |

| 3 | 2400 | 2040 | 1680 | 5080 | 4130 | 3180 | 3840 | 3120 | 2400 | 3840 | 3120 | 2400 | 4230 | 3440 | 2650 | 2000 | 1700 | 1400 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | 1200 | 1020 | 780 | – | – | – | – | – | – | – | – | – | – | – | – | 1000 | 850 | 650 |

Insert Selection

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ..E | KYSP30 | ..E | KYSP30 | ..E | KYSP30 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S3 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

RPG32… High Temp

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ..E | KYSP30 | ..E | KYSP30 | ..E | KYSP30 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S3 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

RPG43… High Temp

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ..E | KYSP30 | ..E | KYSP30 | ..E | KYSP30 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KYS30 | ..E | KYS30 | ..T | KYS30 |

| S3 | ..E | KYS30 | ..T | KYS30 | ..T | KYS30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data