Produkt ähnlich wie:

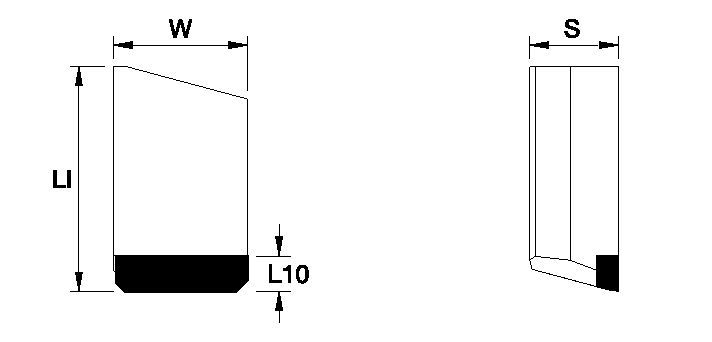

PkD Wendeschneidplatten • KSDR Wiper

Wendeschneidplatten

Material Nummer6042990

ISO Katalog NummerKSDR102SASI Katalog NummerKSDR102S

- N NE-Metalle

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 6042990 |

| ISO Katalog Nummer | KSDR102S |

| ASI Katalog Nummer | KSDR102S |

| Sorte | KD1400 |

| [W] Schneideinsatzbreite | 9.525 mm |

| [W] Schneideinsatzbreite | 0.375 in |

| Mittlere Spandicke [HM] | 0.02 mm |

| Mittlere Spandicke [HM] | 0.0008 in |

Werkstoffe

- NE-Metalle

Grades

KD1400

Auf einem Hartmetallträger aufgelötete PKD-Spitze für die Bearbeitung von NE-Metallen mit hohen Schnittgeschwindigkeiten. KD1400 bietet eine ausgezeichnete Widerstandsfähigkeit gegen Kantenausbrüche mit guten Verschleißeigenschaften. Eine Kühlung wird bevorzugt.

Features and benefits

- Precision ground wiper insert for superior surface finish and flatness.

- Milling insert for aluminum and non-ferrous materials machining.

- Patented locking mechanism guarantees secure insert seating at high RPM's.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Speeds

Empfohlene Startwerte für Schnittgeschwindigkeiten [m/min]

| Werkstoffgruppe | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| Werkstoffgruppe | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| Werkstoffgruppe | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Insert Selection

Auswahlhilfe für PKD-Kassetten • KBDM

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| (Leicht schneidende Geometrie) | (Stabile Geometrie) | |||||

| Verschleiß- festigkeit |  | Zähigkeit | ||||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| (Leicht schneidende Geometrie) | (Stabile Geometrie) | |||||

| Verschleiß- festigkeit |  | Zähigkeit | ||||

| Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data