Produkt ähnlich wie:

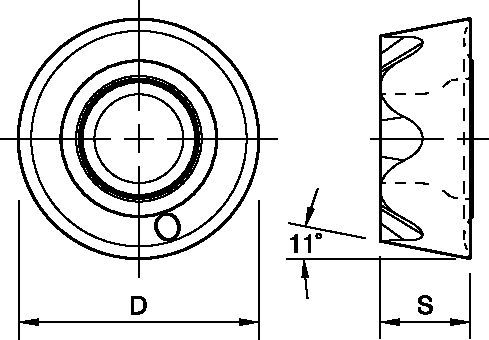

Round Inserts for KSRM • IC 1/2" • RPPT-EGE

Indexable Inserts

Material Nummer5172841

ISO Katalog NummerRPPT43EGEANSI Katalog NummerRPPT43EGE

- P Stahl

- M Rostfreier Stahl

- S Hochwarmfeste Legierungen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 5172841 |

| ISO Katalog Nummer | RPPT43EGE |

| ANSI Katalog Nummer | RPPT43EGE |

| Sorte | KC725M |

| [D] Wendeschneidplatten-Größe (Inkreis) | 12.7 mm |

| [D] Wendeschneidplatten-Größe (Inkreis) | 0.5 in |

| [S] Dicke der Wendeschneidplatte | 4.76 mm |

| [S] Dicke der Wendeschneidplatte | 0.188 in |

| Mittlere Spandicke [HM] | 0.064 mm |

| Mittlere Spandicke [HM] | 0.0025 in |

| Wendeschneidplatte Anzahl der Schneidkanten | 6 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Hochwarmfeste Legierungen

Grades

KC725M

Eine Hochleistungs-Hartmetallsorte mit PVD-TiAlN Beschichtung zur Fräsbearbeitung von Stahl, rostfreiem Stahl und Kugelgraphitguss. Durch die ausgezeichnete Wärmewechselbeständigkeit des Substrats ist dieser Schneidstoff sowohl für Nass- als auch für Trockenbearbeitung ideal geeignet. KC725M wird primär für allgemeine Fräsbearbeitungen und zum Schruppen eingesetzt.

Features and benefits

- -EGE is the first choice for titanium machining.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | .E..LEJ |

| .E..GE | .006 | .010 | .015 | .004 | .008 | .011 | .004 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .009 | .E..GE |

| .S..GEJ | .007 | .017 | .023 | .005 | .013 | .017 | .004 | .011 | .015 | .004 | .010 | .014 | .004 | .010 | .014 | .S..GEJ |

| .S..GE | .007 | .017 | .023 | .005 | .013 | .017 | .004 | .011 | .015 | .004 | .010 | .014 | .004 | .010 | .014 | .S..GE |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .004 | .006 | .008 | .003 | .004 | .006 | .003 | .004 | .005 | .002 | .003 | .005 | .002 | .003 | .005 | .E..LEJ |

| .E..GE | .007 | .012 | .017 | .005 | .009 | .013 | .004 | .008 | .011 | .004 | .007 | .010 | .004 | .007 | .010 | .E..GE |

| .S..GEJ | .008 | .020 | .027 | .006 | .015 | .020 | .005 | .013 | .017 | .005 | .012 | .016 | .005 | .012 | .016 | .S..GEJ |

| .S..GE | .008 | .020 | .027 | .006 | .015 | .020 | .005 | .013 | .017 | .005 | .012 | .016 | .005 | .012 | .016 | .S..GE |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .007 | .010 | .015 | .005 | .007 | .011 | .005 | .006 | .009 | .004 | .006 | .009 | .004 | .006 | .009 | .E..LEJ |

| .E..GE | .012 | .021 | .031 | .009 | .016 | .023 | .008 | .014 | .020 | .007 | .013 | .018 | .007 | .012 | .018 | .E..GE |

| .S..GEJ | .014 | .036 | .049 | .010 | .026 | .035 | .009 | .023 | .031 | .008 | .021 | .028 | .008 | .021 | .028 | .S..GEJ |

| .S..GE | .014 | .036 | .049 | .010 | .026 | .035 | .009 | .023 | .031 | .008 | .021 | .028 | .008 | .021 | .028 | .S..GE |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .005 | .007 | .011 | .004 | .005 | .008 | .003 | .005 | .007 | .003 | .004 | .006 | .003 | .004 | .006 | .E..LEJ |

| .E..GE | .009 | .015 | .023 | .007 | .011 | .017 | .006 | .010 | .014 | .005 | .009 | .014 | .005 | .009 | .013 | .E..GE |

| .S..GEJ | .010 | .026 | .035 | .008 | .019 | .026 | .007 | .017 | .022 | .006 | .015 | .021 | .006 | .015 | .020 | .S..GEJ |

| .S..GE | .010 | .026 | .035 | .008 | .019 | .026 | .007 | .017 | .022 | .006 | .015 | .021 | .006 | .015 | .020 | .S..GE |

Speeds

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KC422M | KC522M | KC725M | KCPK30 | |||||||||

| P | 1 | – | – | – | 1300 | 1130 | 1060 | 1030 | 900 | 840 | 1780 | 1560 | 1450 |

| 2 | – | – | – | 1080 | 950 | 790 | 860 | 760 | 640 | 1100 | 1000 | 900 | |

| 3 | – | – | – | 1000 | 840 | 700 | 790 | 670 | 550 | 1000 | 900 | 820 | |

| 4 | – | – | – | 890 | 730 | 590 | 710 | 590 | 470 | 740 | 690 | 620 | |

| 5 | – | – | – | 730 | 660 | 590 | 590 | 530 | 470 | 1020 | 910 | 830 | |

| 6 | – | – | – | 650 | 490 | 400 | 520 | 400 | 310 | 620 | 540 | – | |

| M | 1 | – | – | – | 800 | 710 | 650 | 670 | 590 | 540 | 820 | 720 | 620 |

| 2 | – | – | – | 730 | 620 | 520 | 610 | 520 | 430 | 730 | 640 | 550 | |

| 3 | – | – | – | 550 | 480 | 370 | 460 | 400 | 310 | 570 | 520 | 460 | |

| K | 1 | – | – | – | 900 | 820 | 720 | – | – | – | 1160 | 1050 | 940 |

| 2 | – | – | – | 710 | 640 | 590 | – | – | – | 920 | 830 | 760 | |

| 3 | – | – | – | 590 | 530 | 480 | – | – | – | 770 | 690 | 640 | |

| N | 1–2 | 4220 | 3720 | 3440 | – | – | – | – | – | – | – | – | – |

| 3 | 3720 | 3440 | 3000 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – |

| 2 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | |

| 3 | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | – | – | – | |

| 4 | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | – | – | – | |

| H | 1 | – | – | – | 470 | 360 | 280 | – | – | – | – | – | – |

Anwendungsdaten

Maximum Linear Ramping and Helical Interpolation from Solid

| Katalognummer | Maximum Ramp Angle (ra) when hx = .01" and ae | Maximum Ramp Depth (ap) per pass when ae | Maximum Ramp Depth (ap) per pass when hx = .01" and ae ae1 | ae1 | Maximum Plunge Depth (ap) when hx = .01" and ae | ae2 | min. Bohrungs- durchmesser (DH min) | max. Flachbohrungs- durchmesser (DH1 max) | Maximum Hole Diameter (No Flat Bottom) |

| KSRM125R4303C125L600 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302C125L600 | 5.95° | 0.061 | 0.250 | 0.413 | 0.250 | 0.500 | 1.674 | 2.001 | 2.500 |

| KSRM125R4303C125L1000 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302C125L1000 | 5.95° | 0.061 | 0.250 | 0.413 | 0.250 | 0.500 | 1.674 | 2.001 | 2.500 |

| KSRM150R4304C125L600 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303C125L600 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM150R4304C125L1000 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303C125L1000 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM125R4303M16L150 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302M16L150 | 6.43° | 0.065 | 0.250 | 0.418 | 0.250 | 0.500 | 1.665 | 2.001 | 2.500 |

| KSRM150R4304M16L150 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303M16L150 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM200R4305S075L197 | 11.43° | 0.250 | 0.250 | 0.499 | 0.250 | 0.500 | 3.001 | 3.501 | 4.000 |

| KSRM200R4303S075L197 | 11.45° | 0.250 | 0.250 | 0.499 | 0.250 | 0.500 | 3.001 | 3.501 | 4.000 |

| KSRM250R4306S075L197 | 8.16° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 4.001 | 4.500 | 5.000 |

| KSRM250R4304S075L197 | 8.16° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 4.001 | 4.500 | 5.000 |

| KSRM300R4307S100L197 | 6.35° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 5.001 | 5.500 | 6.000 |

| KSRM300R4305S100L197 | 6.35° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 5.001 | 5.500 | 6.000 |

Insert Selection

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | .E..LEJ | KC725M | .E..GE | KC725M | .S..GE | KCPK30 |

| P3–P4 | .E..LEJ | KC725M | .S..GE | KCPK30 | – | – |

| P5–P6 | .E..GE | KCPK30 | .S..GE | KCPK30 | – | – |

| M1–M2 | .E..LEJ | KC725M | .E..LEJ | KC725M | .S..GE | KC725M |

| M3 | .S..GEJ | KC725M | .E..GE | KC725M | .S..GE | KCPK30 |

| K1–K2 | – | – | .S..GE | KCPK30 | – | – |

| K3 | – | – | .S..GE | KCPK30 | – | – |

| N1–N2 | .E..LEJ | KC422M | .E..LEJ | KC422M | .E..LEJ | KC422M |

| N3 | .E..LEJ | KC422M | .E..LEJ | KC422M | .E..LEJ | KC422M |

| S1–S2 | .E..LEJ | KC725M | .S..GEJ | KC725M | .S..GE | KC725M |

| S3 | .E..LEJ | KC725M | .S..GEJ | KC725M | .S..GE | KC725M |

| S4 | .E..LEJ | KC725M | .E..GE | KC725M | .S..GE | KC725M |

| H1 | – | – | .S..GE | KC522M | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data