Produit similaire à:

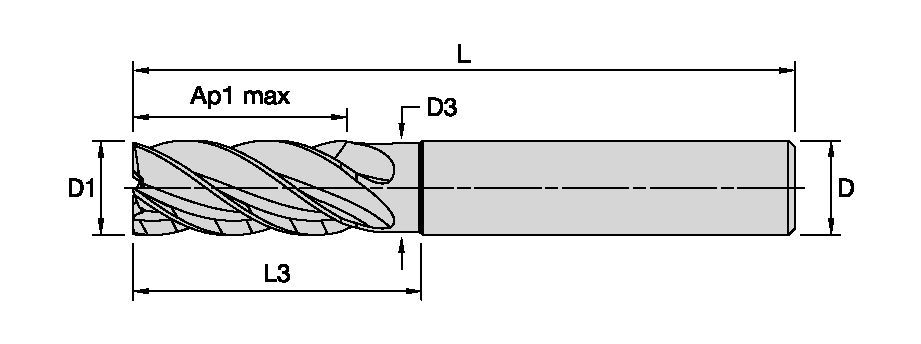

HARVI™ II TE • Square End • 5 Flutes • Necked • Plain Shank • Metric

HARVI™ II TE Five Flute End Mill for Increased MRR Covering the Broadest Range of Applications and Materials;

Roughing and Finishing with One Tool

Numéro de matériel7156179

Ref. ISO CatalogueH2TE5SE1000N022HAMRef. ANSI CatalogueH2TE5SE1000N022HAM

- P Acier

- M Acier inoxydable

- K Fonte

- N Non ferreux

- S Alliages hautes températures

- H Matériaux trempés

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 7156179 |

| Ref. ISO Catalogue | H2TE5SE1000N022HAM |

| Ref. ANSI Catalogue | H2TE5SE1000N022HAM |

| Nuance | KCPM15A |

| Style adaptateur du côté machine | Straight-Cylindrical |

| [D1] Diamètre effectif de coupe | 10 mm |

| [D1] Diamètre effectif de coupe | 0.3937 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 10 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | 0.3937 in |

| [D3] Diamètre de la partie cylindrique du corps | 9.4 mm |

| [D3] Diamètre de la partie cylindrique du corps | 0.3701 in |

| [AP1MAX] 1re profondeur de coupe maximale | 22 mm |

| [AP1MAX] 1re profondeur de coupe maximale | 0.8661 in |

| [L3] Longueur exploitable | 30 mm |

| [L3] Longueur exploitable | 1.1811 in |

| [L] Longueur totale | 72 mm |

| [L] Longueur totale | 2.8346 in |

| [Z] Nombre de goujures | 5 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Non ferreux

- Alliages hautes températures

- Matériaux trempés

Features and benefits

- Versatile solid carbide endmill for steels, stainless steel, high temperature alloys, and cast iron.

- Proprietary core and flute designs with optimum flute spacing for perfect chip formation and highest tool rigidity.

- Unique End Face Design for agressive ramping and plunging operations.

- Unequally spaced flutes and differential helix allow for the broadest range of applications.

- Chip gashes in the flutes ensure optimum chip removal.

- Eccentric relief provides edge stability in a broad range of materials.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Vitesses & Avances

| Table for Feed and Speed Calculation with Adjustment Factor • INCH | |||||||||||||||||||||

|  | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||||||

| Fraisage en bout (A) | KCPM15 | Diamètre | |||||||||||||||||||

| A | B | Vitesse de coupe | frac. | 1/8 | 5/32 | 3/16 | 7/32 | 1/4 | 9/32 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||

| Groupe Matières | ap | ae | ap | Mini | Départ | Maxi | dec. | .1250 | .1563 | .1875 | .2188 | .2500 | .2813 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | |

| P | P0 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | 575 | 660 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 |

| P1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | 575 | 660 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 | |

| P2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 460 | 540 | 620 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 | |

| P3 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 390 | 455 | 520 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 | |

| P4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | 395 | 490 | IPT | 0.0007 | 0.0009 | 0.0011 | 0.0013 | 0.0015 | 0.0017 | 0.0019 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0042 | 0.0044 | |

| P5 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | 265 | 330 | IPT | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0017 | 0.0020 | 0.0025 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | |

| P6 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | 205 | 250 | IPT | 0.0006 | 0.0007 | 0.0008 | 0.0010 | 0.0011 | 0.0013 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0027 | 0.0031 | 0.0032 | |

| M | M1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | 340 | 380 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 |

| M2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | 230 | 260 | IPT | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0017 | 0.0020 | 0.0025 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | |

| M | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 200 | 215 | 230 | IPT | 0.0006 | 0.0007 | 0.0008 | 0.0010 | 0.0011 | 0.0013 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0027 | 0.0031 | 0.0032 | |

| K | K1 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 390 | 440 | 490 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 |

| K2 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | 410 | 460 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 | |

| K3 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | 395 | 430 | IPT | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0017 | 0.0020 | 0.0025 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | |

| S | S1 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | 230 | 300 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 |

| S2 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 80 | 120 | 160 | IPT | 0.0004 | 0.0005 | 0.0007 | 0.0008 | 0.0009 | 0.0010 | 0.0011 | 0.0013 | 0.0017 | 0.0020 | 0.0023 | 0.0027 | 0.0029 | |

| S3 | 1.5 x D1 | 0.5 x D1 | 0.75 x D1 | 80 | 105 | 130 | IPT | 0.0004 | 0.0005 | 0.0007 | 0.0008 | 0.0009 | 0.0010 | 0.0011 | 0.0013 | 0.0017 | 0.0020 | 0.0023 | 0.0027 | 0.0029 | |

| S4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | 180 | 200 | IPT | 0.0005 | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0016 | 0.0019 | 0.0023 | 0.0028 | 0.0031 | 0.0036 | 0.0039 | |

| H | H1 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 260 | 360 | 460 | IPT | 0.0007 | 0.0009 | 0.0011 | 0.0013 | 0.0015 | 0.0017 | 0.0019 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0042 | 0.0044 |

| H2 | 1.5 x D1 | 0.2 x D1 | 1.0 x D1 | 230 | 310 | 390 | IPT | 0.0006 | 0.0007 | 0.0008 | 0.0010 | 0.0011 | 0.0013 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0027 | 0.0031 | 0.0032 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on | |||||||||||||||||||||

| Table for Feed and Speed Calculation with Adjustment Factor • METRIC | |||||||||||||||||||||

|  | Avance par dent recommandée (fz = mm/dent) pour le fraisage en bout (A). Pour le rainurage (B), réduire fz de 20 %. | |||||||||||||||||||

| Fraisage en bout (A) | KCPM15 | Diamètre | |||||||||||||||||||

| A | B | Vitesse de coupe | |||||||||||||||||||

| Groupe Matières | ap | ae | ap | Mini | Départ | Maxi | mm | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 25.0 | |

| P | P0 | 1.5 x D | 0.5 x D | 1.25 x D | 150 | 175 | 200 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 |

| P1 | 1.5 x D | 0.5 x D | 1.25 x D | 150 | 175 | 200 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 | |

| P2 | 1.5 x D | 0.5 x D | 1.25 x D | 140 | 165 | 190 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 | |

| P3 | 1.5 x D | 0.5 x D | 1.25 x D | 120 | 140 | 160 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 | |

| P4 | 1.5 x D | 0.5 x D | 1.25 x D | 90 | 120 | 150 | Fz | 0.024 | 0.030 | 0.036 | 0.043 | 0.049 | 0.054 | 0.059 | 0.069 | 0.077 | 0.084 | 0.091 | 0.097 | 0.107 | |

| P5 | 1.5 x D | 0.5 x D | 1.25 x D | 60 | 80 | 100 | Fz | 0.021 | 0.027 | 0.032 | 0.038 | 0.044 | 0.049 | 0.053 | 0.062 | 0.070 | 0.077 | 0.083 | 0.089 | 0.100 | |

| P6 | 1.5 x D | 0.5 x D | 1.25 x D | 50 | 63 | 75 | Fz | 0.018 | 0.022 | 0.027 | 0.032 | 0.037 | 0.041 | 0.044 | 0.051 | 0.057 | 0.063 | 0.067 | 0.071 | 0.078 | |

| M | M1 | 1.5 x D | 0.5 x D | 1.25 x D | 90 | 103 | 115 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 |

| M2 | 1.5 x D | 0.5 x D | 1.25 x D | 60 | 70 | 80 | Fz | 0.021 | 0.027 | 0.032 | 0.038 | 0.044 | 0.049 | 0.053 | 0.062 | 0.070 | 0.077 | 0.083 | 0.089 | 0.100 | |

| M3 | 1.5 x D | 0.5 x D | 1.0 x D | 60 | 65 | 70 | Fz | 0.018 | 0.022 | 0.027 | 0.032 | 0.037 | 0.041 | 0.044 | 0.051 | 0.057 | 0.063 | 0.067 | 0.071 | 0.078 | |

| K | K1 | 1.5 x D | 0.5 x D | 1.0 x D | 120 | 135 | 150 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 |

| K2 | 1.5 x D | 0.5 x D | 1.0 x D | 110 | 125 | 140 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 | |

| K3 | 1.5 x D | 0.5 x D | 1.0 x D | 110 | 120 | 130 | Fz | 0.021 | 0.027 | 0.032 | 0.038 | 0.044 | 0.049 | 0.053 | 0.062 | 0.070 | 0.077 | 0.083 | 0.089 | 0.100 | |

| S | S1 | 1.5 x D | 0.3 x D | 0.75 x D | 50 | 70 | 90 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 |

| S2 | 1.5 x D | 0.3 x D | 0.75 x D | 25 | 38 | 50 | Fz | 0.014 | 0.018 | 0.021 | 0.025 | 0.029 | 0.032 | 0.035 | 0.041 | 0.046 | 0.051 | 0.055 | 0.059 | 0.067 | |

| S3 | 1.5 x D | 0.5 x D | 0.75 x D | 25 | 33 | 40 | Fz | 0.014 | 0.018 | 0.021 | 0.025 | 0.029 | 0.032 | 0.035 | 0.041 | 0.046 | 0.051 | 0.055 | 0.059 | 0.067 | |

| S4 | 1.5 x D | 0.5 x D | 1.25 x D | 50 | 55 | 60 | Fz | 0.017 | 0.023 | 0.028 | 0.034 | 0.040 | 0.045 | 0.049 | 0.057 | 0.064 | 0.071 | 0.076 | 0.082 | 0.092 | |

| H | H1 | 1.5 x D | 0.5 x D | 1.0 x D | 80 | 110 | 140 | Fz | 0.024 | 0.030 | 0.036 | 0.043 | 0.049 | 0.054 | 0.059 | 0.069 | 0.077 | 0.084 | 0.091 | 0.097 | 0.107 |

| H2 | 1.5 x D | 0.2 x D | 1.0 x D | 70 | 95 | 120 | Fz | 0.018 | 0.022 | 0.027 | 0.032 | 0.037 | 0.041 | 0.044 | 0.051 | 0.057 | 0.063 | 0.067 | 0.071 | 0.078 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on | |||||||||||||||||||||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data