Product Similar To :

NG-K • Groove and Turn • Chip Control

Top Notch™ Groove and Turn Inserts

Material Number5968045

ISO Catalog IDNG3M150LKANSI Catalog IDNG3M150LK

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5968045 |

| ISO Catalog ID | NG3M150LK |

| ANSI Catalog ID | NG3M150LK |

| Grade | KCP25B |

| Insert Size | 3 |

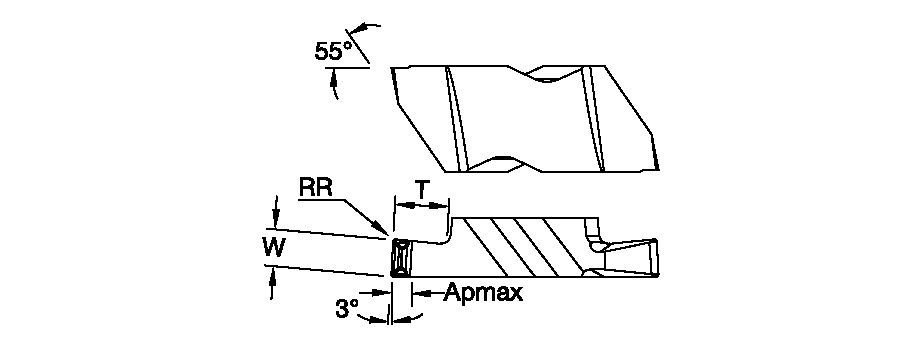

| [W] Cutting Width | 1.5 mm |

| [W] Cutting Width | 0.0591 in |

| [APMAX] Profile AP Maximum | 1.016 mm |

| [APMAX] Profile AP Maximum | 0.04 in |

| [RR] Corner Radius | 0.2 mm |

| [RR] Corner Radius | 0.008 in |

| [T] Cuttg Depth | 2.388 mm |

| [T] Cutting Depth | 0.094 in |

Workpiece Materials

- Steel

- Cast Iron

Grades

KCP25B

Composition: A tough cobalt-enriched carbide grade with a newly designed multilayer MTCVD-TiCN-Al2O3-TiOCN coating with superior interlayer adhesion.

Application: Best general-purpose turning grade for most steels and ferritic and martensitic stainless steels. The substrate design ensures adequate deformation resistance with excellent insert edge strength. Coating layers offer good wear resistance over a wide range of machining conditions and the post-coat treatment minimises microchipping and improves coating adhesion to substrate leading to long tool life and improved workpiece finishes.

Features and benefits

- KENGold™ PVD, multilayer coating for easy wear-detection

- A positive chipbreaker that delivers very low cutting forces for excellent chip control

- Precision-ground inserts for accurate indexing, resulting in reliability and repeatability

- Improved cutting conditions for tool life, stability and rigidity

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use