Product Similar To :

KBDM Series • PCD-Mini-Tipped Carbide Insert • KSDR-E0 • Highspeed Machining

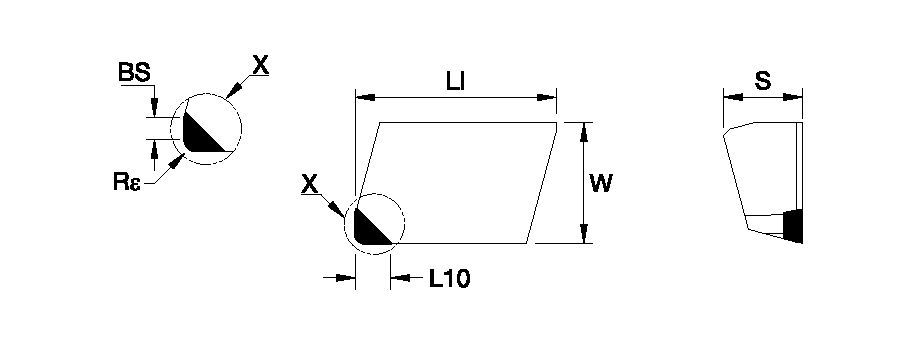

Face milling insert with one cutting edge, precision ground.

Material Number6042983

ISO Catalog IDKSDR100031E0W4SANSI Catalog IDKSDR100031E0W4S

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6042983 |

| ISO Catalog ID | KSDR100031E0W4S |

| ANSI Catalog ID | KSDR100031E0W4S |

| Grade | KD1425 |

| [W] Insert Width | 9.52 mm |

| [W] Insert Width | 0.375 in |

| [BS] Corner Facet Length | 1.52 mm |

| [BS] Corner Facet Length | 0.06 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

Workpiece Materials

- Non-Ferrous

Grades

KD1425

Composition: A multimodal PCD grade with a range of grain sizes brazed onto a carbide substrate.

Application: Engineered for extreme abrasion resistance, combined with good edge strength for demanding applications. An ideal choice for high-silicon aluminium alloys, bi-metallic (AL/GCI) materials, MMC, carbon-fibre reinforced plastics, and other abrasive non-metallic materials.

Features and benefits

- Precision ground insert for best run-out and surface finish.

- Milling insert for aluminum and non-ferrous materials machining.

- Patented locking mechanism guarantees secure insert seating at high RPM's.

- Embedded wiper facet for increased surface finish quality.

- Up to Ap1=2.5mm/.098"

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| Material Group | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 910 | 1980 | 4880 | 910 | 1980 | 4880 |

| 3 | 460 | 610 | 760 | 460 | 610 | 760 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

| Material Group | KD1400 | KD1425 | |||||

| P | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | 3000 | 6500 | 16000 | 3000 | 6500 | 16000 |

| 3 | 1500 | 2000 | 2500 | 1500 | 2000 | 2500 | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Insert Selection

Insert Selection Guide • KBDM

| Material Group | Light | General | Heavy | |||

| (Light geometry) | (Strong geometry) | |||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Material Group | Light | General | Heavy | |||

| (Light geometry) | (Strong geometry) | |||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .KSDR….. | KD1400 | .KSDR….. | KD1400 | .KSDR….. | KD1400 |

| N3 | .KSDR….. | KD1400 | .KSDR….. | KD1425 | .KSDR….. | KD1425 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use