Produit similaire à:

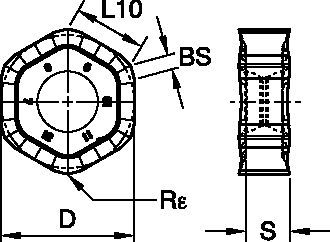

Dodeka MAX™ 45° • Plaquette HNPJ-HD • Usinage ébauche lourde

Plaquette de surfaçage à 12 arêtes de coupe

Numéro de matériel4135436

Ref. ISO CatalogueHNPJ1307ANSNHDRef. ANSI CatalogueHNPJ75ANSNHD

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 4135436 |

| Ref. ISO Catalogue | HNPJ1307ANSNHD |

| Ref. ANSI Catalogue | HNPJ75ANSNHD |

| Nuance | KC520M |

| [D] Taille de plaquette CI | 22.225 mm |

| [D] Taille de plaquette CI | 0.875 in |

| [BS] Longueur de facette d’angle | 1.88 mm |

| [BS] Longueur de facette d’angle | 0.074 in |

| [L10] Longueur d’arête de coupe de la plaquette | 12.832 mm |

| [L10] Longueur d’arête de coupe de la plaquette | 0.5052 in |

| [Rε] Rayon de bec | 1.2 mm |

| [Rε] Rayon de bec | 0.047 in |

| [S] Épaisseur de la plaquette | 7.34 mm |

| [S] Épaisseur de la plaquette | 0.289 in |

| Épaisseur moyenne du copeau [HM] | 0.254 mm |

| Épaisseur moyenne du copeau [HM] | 0.01 in |

| Arêtes de coupe par plaquette | 12 |

Grades

KC520M

Nuance de carbure avec revêtement TiAlN (PVD). Le KC520M est une nuance de carbure revêtu TiAlN-PVD développée spécialement pour les applications générales sur la fonte ductile. Il s'utilise avec ou sans arrosage.

Features and benefits

- Brute de frittage, pour un coût à l’arête de coupe le plus bas possible

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Feeds

Avances de départ recommandées [mm]

| Avance à la dent (Fz) en relation avec le % d'engagement radial (ae) | ||||||

| 30% | 40–100% | |||||

| Géométrie de plaquette | L | M | H | L | M | H |

| .E..GD | 0.11 | 0.31 | 0.54 | 0.10 | 0.28 | 0.49 |

| .S..GD | 0.16 | 0.35 | 0.59 | 0.14 | 0.32 | 0.54 |

| .S..HD | 0.16 | 0.39 | 0.63 | 0.14 | 0.36 | 0.57 |

| L = usinage léger | ||||||

Recommended Starting Feeds [IPT]

| Avance à la dent (Fz) en relation avec le % d'engagement radial (ae) | ||||||

| 30% | 40–100% | |||||

| Géométrie de plaquette | L | M | H | L | M | H |

| .E..GD | 0.004 | 0.012 | 0.022 | 0.004 | 0.011 | 0.020 |

| .S..GD | 0.006 | 0.014 | 0.023 | 0.006 | 0.013 | 0.021 |

| .S..HD | 0.006 | 0.015 | 0.025 | 0.006 | 0.014 | 0.023 |

| L = Light Machining | ||||||

Speeds

Vitesses de départ recommandées [m/mn]

| nuance | K313 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM30 | KCSM40 | KTPK20 | KY3500 | |||||||||||||||||||||||||||

| Chip Thickness hex Inch | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | ||||||||||||||

| Groupe Matières | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | |

| P | 1 | – | – | – | – | – | – | 395 | 345 | 325 | 310 | 275 | 260 | – | – | – | 545 | 475 | 445 | 370 | 340 | 310 | – | – | – | 355 | 310 | 295 | 440 | 380 | 350 | 420 | 375 | 345 | 430 | 360 | 300 | – | – | – |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 265 | 230 | 190 | – | – | – | 335 | 305 | 275 | 350 | 315 | 280 | – | – | – | 300 | 260 | 215 | 365 | 320 | 260 | 360 | 320 | 255 | 315 | 260 | 240 | – | – | – | |

| 3 | – | – | – | – | – | – | 305 | 260 | 210 | 240 | 205 | 170 | – | – | – | 305 | 275 | 245 | 330 | 280 | 245 | – | – | – | 275 | 235 | 190 | 340 | 285 | 234 | 335 | 275 | 230 | 290 | 240 | 215 | – | – | – | |

| 4 | – | – | – | – | – | – | 270 | 220 | 180 | 215 | 180 | 145 | – | – | – | 270 | 220 | 190 | 280 | 245 | 190 | – | – | – | 245 | 205 | 160 | 300 | 245 | 195 | 285 | 240 | 190 | 250 | 215 | 190 | – | – | – | |

| 5 | – | – | – | – | – | – | 220 | 205 | 180 | 180 | 160 | 145 | – | – | – | 225 | 200 | 180 | 250 | 190 | 150 | – | – | – | 205 | 185 | 160 | 245 | 220 | 190 | 240 | 210 | 180 | 220 | 200 | 180 | – | – | – | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 155 | 120 | 95 | – | – | – | 190 | 160 | 130 | 190 | 150 | 130 | – | – | – | 180 | 140 | 110 | 215 | 165 | 130 | 210 | 155 | 120 | 190 | 155 | 120 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | 205 | 180 | 160 | – | – | – | 245 | 220 | 185 | – | – | – | – | – | – | 235 | 205 | 185 | 255 | 210 | 190 | 290 | 230 | 200 | 260 | 210 | 180 | – | – | – |

| 2 | – | – | – | – | – | – | 220 | 190 | 180 | 185 | 155 | 130 | – | – | – | 220 | 190 | 170 | – | – | – | – | – | – | 210 | 180 | 150 | 230 | 190 | 150 | 260 | 205 | 170 | 235 | 200 | 165 | – | – | – | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | 140 | 120 | 95 | – | – | – | 175 | 155 | 140 | – | – | – | – | – | – | 155 | 140 | 110 | 170 | 145 | 115 | 190 | 160 | 125 | 175 | 145 | 120 | – | – | – | |

| K | 1 | 190 | 165 | 140 | – | – | – | 275 | 245 | 220 | – | – | – | 505 | 460 | 410 | 355 | 320 | 290 | 490 | 390 | 280 | 430 | 340 | 280 | – | – | – | – | – | – | – | – | – | 275 | 235 | 190 | 965 | 875 | 780 |

| 2 | – | – | – | – | – | – | 215 | 190 | 180 | – | – | – | 400 | 355 | 330 | 280 | 250 | 230 | 335 | 290 | 225 | 330 | 270 | 220 | – | – | – | – | – | – | – | – | – | 220 | 180 | 155 | 760 | 685 | 635 | |

| 3 | – | – | – | – | – | – | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 235 | 210 | 190 | 280 | 230 | 190 | 250 | 210 | 165 | – | – | – | – | – | – | – | – | – | 180 | 155 | 125 | – | – | – | |

| N | 1 | 875 | 765 | 660 | 1335 | 1185 | 1090 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 1185 | 1090 | 950 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 1185 | 1090 | 950 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 45 | 40 | 35 | 50 | 45 | 35 | 60 | 45 | 30 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 45 | 40 | 35 | 50 | 45 | 35 | 65 | 45 | 30 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 45 | 35 | 65 | 50 | 35 | 75 | 50 | 35 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 35 | – | – | – | 60 | 50 | 40 | – | – | – | – | – | – | 65 | 60 | 40 | 70 | 65 | 45 | 90 | 70 | 45 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 120 | 90 | – | – | – | – | – | – | – | – | – |

| Recommended starting speeds are in bold type. As the average chip thickness increases, speed should be decreased. Material groups P, M, K, and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||

| nuance | K313 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM30 | KCSM40 | KTPK20 | KY3500 | |||||||||||||||||||||||||||

| Chip Thickness hex Inch | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | Mini | Maxi | ||||||||||||||

| Groupe Matières | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | Maxi | Départ | Mini | |

| P | 1 | – | – | – | – | – | – | 1295 | 1115 | 1065 | 1015 | 900 | 855 | – | – | – | 1790 | 1560 | 1460 | 1215 | 1115 | 1015 | – | – | – | 1165 | 1015 | 970 | 1445 | 1245 | 1150 | 1380 | 1230 | 1130 | 1410 | 1180 | 985 | – | – | – |

| 2 | – | – | – | – | – | – | 1085 | 950 | 785 | 870 | 755 | 625 | – | – | – | 1100 | 1000 | 900 | 1150 | 1035 | 920 | – | – | – | 985 | 855 | 705 | 1200 | 1050 | 855 | 1180 | 1050 | 835 | 1035 | 855 | 785 | – | – | – | |

| 3 | – | – | – | – | – | – | 1000 | 855 | 690 | 785 | 675 | 560 | – | – | – | 1000 | 900 | 805 | 1085 | 920 | 805 | – | – | – | 900 | 770 | 625 | 1115 | 935 | 770 | 1100 | 900 | 755 | 950 | 785 | 705 | – | – | – | |

| 4 | – | – | – | – | – | – | 885 | 720 | 590 | 705 | 590 | 475 | – | – | – | 885 | 720 | 625 | 920 | 805 | 625 | – | – | – | 805 | 675 | 525 | 985 | 805 | 640 | 935 | 785 | 625 | 820 | 705 | 625 | – | – | – | |

| 5 | – | – | – | – | – | – | 720 | 675 | 590 | 590 | 525 | 475 | – | – | – | 740 | 655 | 590 | 820 | 625 | 490 | – | – | – | 675 | 605 | 525 | 805 | 720 | 625 | 785 | 690 | 590 | 720 | 655 | 590 | – | – | – | |

| 6 | – | – | – | – | – | – | 655 | 490 | 395 | 510 | 395 | 310 | – | – | – | 625 | 525 | 425 | 625 | 490 | 425 | – | – | – | 590 | 460 | 360 | 705 | 540 | 425 | 690 | 510 | 395 | 625 | 510 | 395 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 805 | 705 | 655 | 675 | 590 | 525 | – | – | – | 805 | 720 | 605 | – | – | – | – | – | – | 770 | 675 | 605 | 835 | 690 | 625 | 950 | 755 | 655 | 855 | 690 | 590 | – | – | – |

| 2 | – | – | – | – | – | – | 720 | 625 | 590 | 605 | 510 | 425 | – | – | – | 720 | 625 | 560 | – | – | – | – | – | – | 690 | 590 | 490 | 755 | 625 | 490 | 855 | 675 | 560 | 770 | 655 | 540 | – | – | – | |

| 3 | – | – | – | – | – | – | 590 | 525 | 475 | 460 | 395 | 310 | – | – | – | 575 | 510 | 460 | – | – | – | – | – | – | 510 | 460 | 360 | 560 | 475 | 375 | 625 | 525 | 410 | 575 | 475 | 395 | – | – | – | |

| K | 1 | 625 | 540 | 460 | – | – | – | 900 | 805 | 720 | – | – | – | 1655 | 1510 | 1345 | 1165 | 1050 | 950 | 1610 | 1280 | 920 | 1410 | 1115 | 920 | – | – | – | – | – | – | – | – | – | 900 | 770 | 625 | 3165 | 2870 | 2560 |

| 2 | – | – | – | – | – | – | 705 | 625 | 590 | – | – | – | 1310 | 1165 | 1085 | 920 | 820 | 755 | 1100 | 950 | 740 | 1085 | 885 | 720 | – | – | – | – | – | – | – | – | – | 720 | 590 | 510 | 2495 | 2245 | 2085 | |

| 3 | – | – | – | – | – | – | 590 | 525 | 475 | – | – | – | 1100 | 985 | 900 | 700 | 690 | 625 | 920 | 755 | 625 | 820 | 690 | 540 | – | – | – | – | – | – | – | – | – | 590 | 510 | 410 | – | – | – | |

| N | 1 | 2870 | 2510 | 2165 | 4380 | 3890 | 3575 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3890 | 3575 | 3115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3890 | 3575 | 3115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 130 | 115 | 165 | 150 | 115 | 195 | 150 | 100 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 130 | 115 | 165 | 150 | 115 | 215 | 150 | 100 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 150 | 115 | 215 | 165 | 115 | 245 | 165 | 115 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 115 | – | – | – | 195 | 165 | 130 | – | – | – | – | – | – | 215 | 195 | 130 | 230 | 215 | 150 | 295 | 230 | 150 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 475 | 360 | 280 | – | – | – | – | – | – | – | – | – | 525 | 395 | 310 | – | – | – | – | – | – | 525 | 395 | 295 | – | – | – | – | – | – | – | – | – |

| Recommended starting speeds are in bold type. As the average chip thickness increases, speed should be decreased. Material groups P, M, K, and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||

| Groupe Matières | Travaux légers | Usinage | Travaux lourds | |||

| P1–P2 | .E..GD | KCPM40 | .S..GD | KCPK30 | .S..HD | KC725M |

| P3–P4 | .E..GD | KCPK30 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..GD | KC725M | .S..GD | KC725M | .S..HD | KCPM40 |

| M1–M2 | .E..GD | KC725M | .S..GD | KC725M | .S..HD | KCSM40 |

| M3 | .E..GD | KCPM40 | .S..GD | KC725M | .S..HD | KCPM40 |

| K1–K2 | .S..GD | KCK15 | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .S..GD | KCK15 | .S..GD | KCK15 | .S..HD | KCPK30 |

| S1–S2 | .E..GD | KC725M | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..GD | KCPM40 | .S..GD | KC725M | .S..HD | KCSM40 |

| S4 | .E..GD | KC725M | .S..GD | KC725M | .S..HD | KCSM40 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data