Product Similar To :

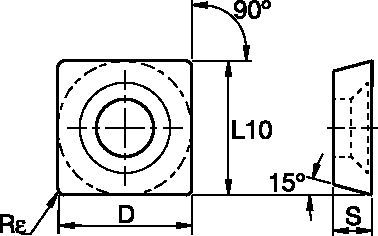

Inserts for Chamfer Mill • SDEB KIPR

Indexable Inserts

Material Number1157518

ISO Catalog IDSDEB080208ANSI Catalog IDSDEB26152

- P Steel

- M Stainless Steel

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1157518 |

| ISO Catalog ID | SDEB080208 |

| ANSI Catalog ID | SDEB26152 |

| Grade | KC735M |

| [D] Insert IC Size | 8.3 mm |

| [D] Insert IC Size | 0.327 in |

| [S] Insert Thickness | 2.381 mm |

| [S] Insert Thickness | 0.0938 in |

| [L10] Insert Cutting Edge Length | 8.306 mm |

| [L10] Insert Cutting Edge Length | 0.327 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.038 mm |

| Average Chip Thickness [HM] | 0.0015 in |

| Cutting Edges per Insert | 4 |

Workpiece Materials

- Steel

- Stainless Steel

Grades

KC735M

PVD/TiN coated carbide grade. This grade offers an unusual combination of high toughness and wear resistance. Even under extreme toughness requirements, it achieves outstanding results in general and heavy-machining applications. Suitable for dry and wet machining.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Chamfer Mills • 30°

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| SDEB | .004 | .015 | .030 | .003 | .011 | .022 | .003 | .009 | .019 | .003 | .009 | .018 | .002 | .009 | .017 | SDEB |

Chamfer Mills • KIPR • 45°

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| SDEB | .005 | .018 | .037 | .004 | .013 | .027 | .003 | .012 | .023 | .003 | .011 | .022 | .003 | .011 | .021 | SDEB |

| Light | General | Heavy |

Chamfer Mills • 45°

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| SEH. | .005 | .018 | .037 | .004 | .013 | .027 | .003 | .012 | .023 | .003 | .011 | .022 | .003 | .011 | .021 | SEH. |

| Light | General | Heavy |

Chamfer Mills • 60°

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| SDEB | .007 | .026 | .053 | .005 | .019 | .038 | .005 | .016 | .033 | .004 | .015 | .031 | .004 | .015 | .030 | SDEB |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KC510M | KC520M | KC725M | KCK15 | KCPK30 | |||||||||||

| P | 1 | – | – | – | – | – | – | 1030 | 900 | 840 | – | – | – | 1780 | 1560 | 1450 |

| 2 | – | – | – | – | – | – | 860 | 760 | 640 | – | – | – | 1100 | 1000 | 900 | |

| 3 | – | – | – | – | – | – | 790 | 670 | 550 | – | – | – | 1000 | 900 | 820 | |

| 4 | – | – | – | – | – | – | 710 | 590 | 470 | – | – | – | 740 | 690 | 620 | |

| 5 | – | – | – | – | – | – | 590 | 530 | 470 | – | – | – | 1020 | 910 | 830 | |

| 6 | – | – | – | – | – | – | 520 | 400 | 310 | – | – | – | 620 | 540 | - | |

| M | 1 | – | – | – | – | – | – | 670 | 590 | 540 | – | – | – | 820 | 720 | 620 |

| 2 | – | – | – | – | – | – | 610 | 520 | 430 | – | – | – | 730 | 640 | 550 | |

| 3 | – | – | – | – | – | – | 460 | 400 | 310 | – | – | – | 570 | 520 | 460 | |

| K | 1 | – | – | – | 1060 | 960 | 850 | – | – | – | 1660 | 1510 | 1340 | 1160 | 1050 | 940 |

| 2 | – | – | – | 830 | 740 | 700 | – | – | – | 1310 | 1170 | 1090 | 920 | 830 | 760 | |

| 3 | – | – | – | 700 | 620 | 560 | – | – | – | 1100 | 980 | 900 | 770 | 690 | 640 | |

| N | 1–2 | 2520 | 2240 | 2060 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 2280 | 2100 | 1920 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | KC520M | KC725M | KCPK30 | |||||||

| P | 1 | – | – | – | 1030 | 900 | 840 | 1780 | 1560 | 1450 |

| 2 | – | – | – | 860 | 760 | 640 | 1100 | 1000 | 900 | |

| 3 | – | – | – | 790 | 670 | 550 | 1000 | 900 | 820 | |

| 4 | – | – | – | 710 | 590 | 470 | 740 | 690 | 620 | |

| 5 | – | – | – | 590 | 530 | 470 | 1020 | 910 | 830 | |

| 6 | – | – | – | 520 | 400 | 310 | 620 | 540 | - | |

| M | 1 | – | – | – | 670 | 590 | 540 | 820 | 720 | 620 |

| 2 | – | – | – | 610 | 520 | 430 | 730 | 640 | 550 | |

| 3 | – | – | – | 460 | 400 | 310 | 570 | 520 | 460 | |

| K | 1 | 1060 | 960 | 850 | – | – | – | 1160 | 1050 | 940 |

| 2 | 830 | 740 | 700 | – | – | – | 920 | 830 | 760 | |

| 3 | 700 | 620 | 560 | – | – | – | 770 | 690 | 640 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | SDEB | KC725M | SDEB | KC725M | SDEB | KCPK30 |

| P3–P4 | SDEB | KC725M | SDEB | KCPK30 | SDEB | KCPK30 |

| P5–P6 | SDEB | KCPK30 | SDEB | KCPK30 | SDEB | KCPK30 |

| M1–M2 | SDEB | KC725M | SDEB | KC725M | SDEB | KCPK30 |

| M3 | SDEB | KC725M | SDEB | KCPK30 | SDEB | KCPK30 |

| K1–K2 | SDEB | KC520M | SDEB | KC520M | SDEB | KCPK30 |

| K3 | SDEB | KC520M | SDEB | KCPK30 | SDEB | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| S3 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| S4 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| H1 | – | – | – | – | – | – |

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | SEHT | KC725M | SEHT | KC725M | SEHT-T | KCPK30 |

| P3–P4 | SEHT | KC725M | SEHT-T | KCPK30 | SEHT-T | KCPK30 |

| P5–P6 | SEHT-T | KCPK30 | SEHT-T | KCPK30 | SEHT-T | KCPK30 |

| M1–M2 | SEHT | KC725M | SEHT | KC725M | SEHT-T | KCPK30 |

| M3 | SEHT | KC725M | SEHT-T | KCPK30 | SEHT-T | KCPK30 |

| K1–K2 | SEHW | KC520M | SEHW | KC520M | SEHW-T | KCPK30 |

| K3 | SEHW | KC520M | SEHW-T | KCPK30 | SEHW-T | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | SEHT | KC725M | SEHT | KC725M | SEHT-T | KC725M |

| S3 | SEHT | KC725M | SEHT | KC725M | SEHT-T | KC725M |

| S4 | SEHT | KC725M | SEHT-T | KC725M | SEHT-T | KC725M |

| H1 | – | – | – | – | – | – |

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | SDEB | KC725M | SDEB | KC725M | SDEB | KCPK30 |

| P3–P4 | SDEB | KC725M | SDEB | KCPK30 | SDEB | KCPK30 |

| P5–P6 | SDEB | KCPK30 | SDEB | KCPK30 | SDEB | KCPK30 |

| M1–M2 | SDEB | KC725M | SDEB | KC725M | SDEB | KCPK30 |

| M3 | SDEB | KC725M | SDEB | KCPK30 | SDEB | KCPK30 |

| K1–K2 | SDEB | KC520M | SDEB | KC520M | SDEB | KCPK30 |

| K3 | SDEB | KC520M | SDEB | KCPK30 | SDEB | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| S3 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| S4 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| H1 | – | – | – | – | – | – |

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | SDEB | KC725M | SDEB | KC725M | SDEB | KCPK30 |

| P3–P4 | SDEB | KC725M | SDEB | KCPK30 | SDEB | KCPK30 |

| P5–P6 | SDEB | KCPK30 | SDEB | KCPK30 | SDEB | KCPK30 |

| M1–M2 | SDEB | KC725M | SDEB | KC725M | SDEB | KCPK30 |

| M3 | SDEB | KC725M | SDEB | KCPK30 | SDEB | KCPK30 |

| K1–K2 | SDEB | KC520M | SDEB | KC520M | SDEB | KCPK30 |

| K3 | SDEB | KC520M | SDEB | KCPK30 | SDEB | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| S3 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| S4 | SDEB | KC725M | SDEB | KC725M | SDEB | KC725M |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use