欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称: {{SolutionName}}- 产品

- /

- KSEM™ • 倒角刀片 • TPGX-GD 槽型

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

KSEM™ • 倒角刀片 • TPGX-GD 槽型

模块化钻孔 • 适用于 KSEM™ 的硬质合金刀片

Features and benefits

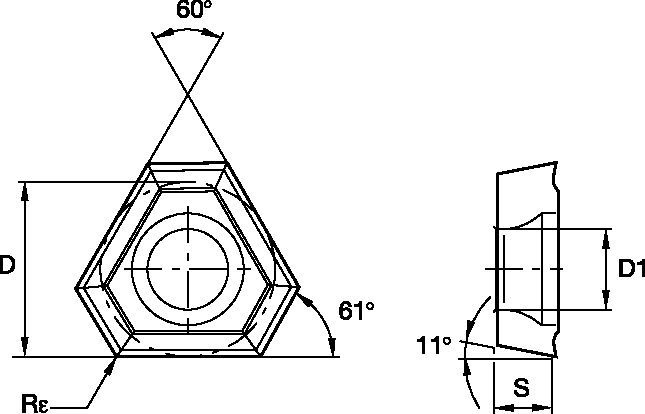

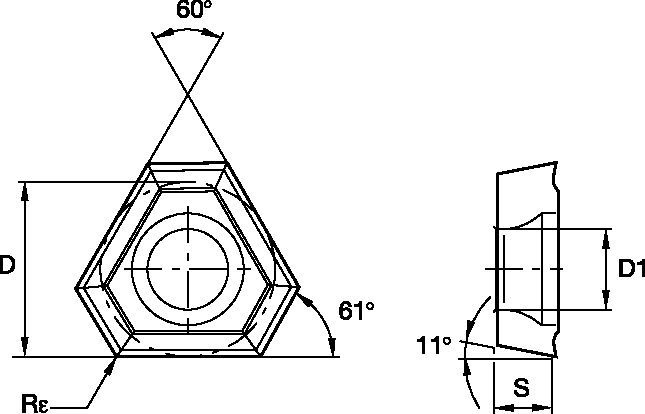

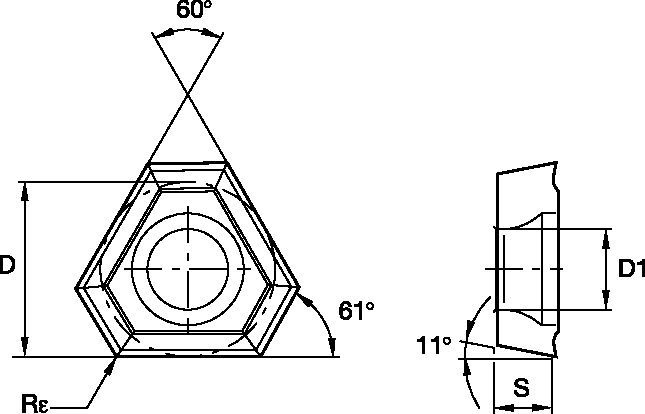

- TPGX-GD 刀片,用于具有 45°倒角的 KSEM 钻体。

- 三个切削刃。

| KSEM™ FEG/PC • Tolerances | Metric |

| D1 metric | tolerance k7 |

| 12,5–18 | +0,001/+0,019 |

|

|

+0,002/+0,023 |

|

|

+0,002/+0,027 |

| KSEM™ FEG/PC • Tolerances | Inch |

| D1 inch | tolerance k7 |

| .500–.709 | +.0000/+.0008 |

|

|

+.0000/+.0009 |

|

|

+.0000/+.0010 |

| KSEM™ HP/SPL • Tolerances | Metric |

| D1 metric | tolerance h8 +/- |

| 12,5–18 | +0,000/-0,027 |

|

|

+0,000/-0,033 |

|

|

+0,000/-0,039 |

| KSEM™ HP/SPL • Tolerances | Inch |

| D1 inch | tolerance h8 +/- |

| .500–.709 | +.000/-.0010 |

|

|

+.000/-.0013 |

|

|

+.000/-.0015 |

| D1 | 3 x D | 5 x D | 7 x D | 10 x D | |||||||||||

| mm | in | L | L1 | L4 max | wrench | L | L1 | L4 max | wrench | L | L4 max | wrench | L | L4 max | wrench |

| 12,50 | .4921 | 111 | - | 42 | 170.294 | 139 | - | 70 | 170.294 | 167 | 98 | 170.295 | 195 | 125 | 170.296 |

| 13,00 | .5118 | 111 | - | 42 | 170.294 | 139 | - | 70 | 170.294 | 167 | 98 | 170.295 | 200 | 130 | 170.296 |

| 13,50 | .5315 | 111 | - | 42 | 170.294 | 139 | - | 70 | 170.294 | 167 | 98 | 170.295 | 205 | 135 | 170.296 |

| 13,51 | .5319 | 111 | - | 42 | 170.289 | 139 | - | 70 | 170.289 | 167 | 98 | 170.290 | 205 | 135 | 170.291 |

| 14,00 | .5512 | 111 | - | 42 | 170.289 | 139 | - | 70 | 170.289 | 167 | 98 | 170.290 | 210 | 140 | 170.291 |

| 14,50 | .5709 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 186 | 112 | 170.290 | 220 | 145 | 170.291 |

| 14,51 | .5713 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 186 | 112 | 170.290 | 220 | 145 | 170.291 |

| 15,00 | .5906 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 186 | 112 | 170.290 | 225 | 150 | 170.291 |

| 15,50 | .6102 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 186 | 112 | 170.290 | 230 | 155 | 170.291 |

| 16,00 | .6299 | 122 | - | 48 | 170.270 | 154 | - | 80 | 170.270 | 186 | 112 | 170.270 | 234 | 160 | 170.271 |

| 16,50 | .6496 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 202 | 126 | 170.271 | 241 | 165 | 170.281 |

| 17,00 | .6693 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 202 | 126 | 170.271 | 246 | 170 | 170.281 |

| 17,50 | .6890 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 202 | 126 | 170.271 | 251 | 175 | 170.281 |

| 18,00 | .7087 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 202 | 126 | 170.271 | 256 | 180 | 170.281 |

| 18,01 | .7091 | - | 184 | - | 100 | 170.270 | 170.271 | 269 | 185 | 170.281 | |||||

| 18,50 | .7283 | 144 | - | 60 | 170.270 | 184 | - | 100 | 170.270 | 224 | 140 | 170.271 | 269 | 185 | 170.281 |

| 19,00 | .7480 | 144 | - | 60 | 170.270 | 184 | - | 100 | 170.270 | 224 | 140 | 170.271 | 274 | 190 | 170.281 |

| 19,50 | .7677 | 144 | - | 60 | 170.270 | 184 | - | 100 | 170.270 | 224 | 140 | 170.271 | 279 | 195 | 170.281 |

| 20,00 | .7874 | 153 | - | 60 | 170.272 | 197 | - | 100 | 170.272 | 241 | 140 | 170.273 | 297 | 200 | 170.282 |

| 20,50 | .8071 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 241 | 154 | 170.273 | 297 | 205 | 170.282 |

| 21,00 | .8268 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 241 | 154 | 170.273 | 297 | 210 | 170.282 |

| 21,50 | .8465 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 241 | 154 | 170.273 | 307 | 215 | 170.282 |

| 22,00 | .8661 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 241 | 154 | 170.273 | 307 | 220 | 170.282 |

| 22,01 | .8665 | - | 209 | - | 120 | 170.272 | 170.273 | 319 | 225 | 170.282 | |||||

| 22,50 | .8858 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 257 | 168 | 170.273 | 319 | 225 | 170.282 |

| 23,00 | .9055 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 257 | 168 | 170.273 | 319 | 230 | 170.282 |

| 23,50 | .9252 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 257 | 168 | 170.273 | 329 | 235 | 170.282 |

| 24,00 | .9449 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 257 | 168 | 170.273 | 329 | 240 | 170.282 |

| 24,01 | .9453 | - | 226 | - | 130 | 170.274 | 346 | 245 | 170.283 | ||||||

| 24,50 | .9646 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 278 | 182 | 170.275 | 346 | 245 | 170.283 |

| 25,00 | .9843 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 278 | 182 | 170.275 | 346 | 250 | 170.283 |

| 25,50 | 10.039 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 278 | 182 | 170.275 | 356 | 255 | 170.283 |

| 26,00 | 10.236 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 278 | 182 | 170.275 | 356 | 260 | 170.283 |

| 26,01 | 10.240 | - | 238 | - | 140 | 170.274 | 170.275 | 363 | 265 | 170.283 | |||||

| 26,50 | 10.433 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 294 | 196 | 170.275 | 363 | 265 | 170.283 |

| 27,00 | 10.630 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 294 | 196 | 170.275 | 368 | 270 | 170.283 |

| 27,50 | 10.827 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 294 | 196 | 170.275 | 378 | 275 | 170.283 |

| 28,00 | 11.024 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 294 | 196 | 170.275 | 378 | 280 | 170.283 |

| 28,02 | 11.028 | - | 250 | - | 150 | 170.276 | 390 | 285 | 170.284 | ||||||

| 28,50 | 11.220 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | 310 | 210 | 170.277 | 390 | 285 | 170.284 |

| 29,00 | 11.417 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | 310 | 210 | 170.277 | 390 | 290 | 170.284 |

| 29,50 | 11.614 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | 310 | 210 | 170.277 | 400 | 295 | 170.284 |

| 30,00 | 11.811 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | 310 | 210 | 170.277 | 400 | 300 | 170.284 |

| 30,01 | 11.815 | - | 264 | - | 160 | 170.276 | 170.277 | 414 | 305 | 170.284 | |||||

| 30,50 | 12.008 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | 328 | 224 | 170.277 | |||

| 31,00 | 12.205 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | 328 | 224 | 170.277 | 414 | 310 | 170.284 |

| 31,50 | 12.402 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | 328 | 224 | 170.277 | |||

| 32,00 | 12.598 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | 328 | 224 | 170.277 | 424 | 320 | 170.284 |

| 32,01 | 12.602 | 220 | 159 | 99 | 170.276 | 293 | 225 | 165 | 170.277 | ||||||

| 33,00 | 12.992 | 227 | 159 | 99 | 170.276 | 293 | 225 | 165 | 170.277 | ||||||

| 34,00 | 13.386 | 225 | 157 | 102 | 170.276 | 293 | 225 | 170 | 170.277 | ||||||

| 35,00 | 13.780 | 235 | 167 | 105 | 170.276 | 305 | 237 | 175 | 170.277 | ||||||

| 36,00 | 14.173 | 233 | 165 | 108 | 170.276 | 305 | 237 | 180 | 170.277 | ||||||

| 36,01 | 14.177 | 237 | 176 | 111 | 170.276 | 318 | 250 | 185 | 170.277 | ||||||

| 37,00 | 14.567 | 244 | 176 | 111 | 170.276 | 318 | 250 | 185 | 170.277 | ||||||

| 38,00 | 14.961 | 242 | 174 | 114 | 170.276 | 318 | 250 | 190 | 170.277 | ||||||

| 39,00 | 15.354 | 252 | 184 | 117 | 170.276 | 330 | 262 | 195 | 170.277 | ||||||

| 40,00 | 15.748 | 250 | 182 | 120 | 170.276 | 330 | 262 | 200 | 170.277 | ||||||

| 7 x D | 10 x D | ||||||||||||||

| D1 | 3 x D | 5 x D | L1 | L4 max | wrench | L1 | L4 max | wrench | |||||||

| mm | in | L | L1 | L4 max | wrench | L | L1 | L4 max | wrench | 5.63 | 3.50 | 170.295 | 7.75 | 5.00 | 170.296 |

| 12,50 | .4921 | 111 | - | 42 | 170.294 | 139 | - | 70 | 170.294 | 6.13 | 3.50 | 170.295 | |||

| 13,00 | .5118 | 111 | - | 42 | 170.294 | 139 | - | 70 | 170.294 | 6.25 | 3.56 | 170.295 | 7.88 | 5.09 | 170.296 |

| 13,50 | .5315 | 111 | - | 42 | 170.294 | 139 | - | 70 | 170.294 | 6.25 | 3.61 | 170.295 | 8.00 | 5.16 | 170.296 |

| 13,51 | .5319 | 111 | - | 42 | 170.289 | 139 | - | 70 | 170.289 | 6.38 | 3.72 | 170.295 | 8.13 | 5.31 | 170.296 |

| 14,00 | .5512 | 111 | - | 42 | 170.289 | 139 | - | 70 | 170.289 | 6.50 | 3.83 | 170.290 | 8.25 | 5.47 | 170.291 |

| 14,50 | .5709 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 6.63 | 3.94 | 170.290 | 8.38 | 5.63 | 170.291 |

| 14,51 | .5713 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 6.75 | 4.05 | 170.290 | 8.50 | 5.78 | 170.291 |

| 15,00 | .5906 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 6.88 | 4.16 | 170.290 | 8.75 | 5.94 | 170.291 |

| 15,50 | .6102 | 122 | - | 48 | 170.289 | 154 | - | 80 | 170.289 | 7.00 | 4.27 | 170.290 | 8.88 | 6.09 | 170.291 |

| 16,00 | .6299 | 122 | - | 48 | 170.270 | 154 | - | 80 | 170.270 | 7.38 | 4.41 | 170.270 | 9.00 | 6.25 | 170.281 |

| 16,50 | .6496 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 8.00 | 4.59 | 170.271 | 9.13 | 6.34 | 170.281 |

| 17,00 | .6693 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 8.00 | 4.96 | 170.271 | 9.38 | 6.56 | 170.281 |

| 17,50 | .6890 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 8.00 | 4.96 | 170.271 | 9.75 | 6.88 | 170.281 |

| 18,00 | .7087 | 130 | - | 54 | 170.270 | 166 | - | 90 | 170.270 | 8.88 | 5.51 | 170.271 | 10.25 | 7.19 | 170.281 |

| 18,01 | .7091 | - | 184 | - | 100 | 170.270 | 8.88 | 5.51 | 170.271 | 10.50 | 7.50 | 170.281 | |||

| 18,50 | .7283 | 144 | - | 60 | 170.270 | 184 | - | 100 | 170.270 | 9.88 | 5.51 | 170.281 | 11.50 | 7.50 | 170.281 |

| 19,00 | .7480 | 144 | - | 60 | 170.270 | 184 | - | 100 | 170.270 | 8.88 | 5.51 | 170.271 | |||

| 19,50 | .7677 | 144 | - | 60 | 170.270 | 184 | - | 100 | 170.270 | 11.50 | 7.59 | 170.281 | |||

| 20,00 | .7874 | 153 | - | 60 | 170.272 | 197 | - | 100 | 170.272 | 9.88 | 5.51 | 170.281 | 11.75 | 7.81 | 170.281 |

| 20,50 | .8071 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 10.25 | 6.06 | 170.273 | 12.13 | 8.13 | 170.282 |

| 21,00 | .8268 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 10.25 | 6.06 | 170.273 | 12.50 | 8.44 | 170.282 |

| 21,50 | .8465 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 10.88 | 6.61 | 170.282 | 12.75 | 8.75 | 170.282 |

| 22,00 | .8661 | 153 | - | 66 | 170.272 | 197 | - | 110 | 170.272 | 11.13 | 6.61 | 170.282 | |||

| 22,01 | .8665 | - | 209 | - | 120 | 170.272 | 10.88 | 6.61 | 170.282 | 12.88 | 8.84 | 170.282 | |||

| 22,50 | .8858 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 10.88 | 6.61 | 170.282 | 13.13 | 9.06 | 170.282 |

| 23,00 | .9055 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 10.88 | 6.61 | 170.282 | 13.44 | 9.38 | 170.282 |

| 23,50 | .9252 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 11.63 | 7.17 | 170.275 | 13.88 | 9.69 | 170.283 |

| 24,00 | .9449 | 161 | - | 72 | 170.272 | 209 | - | 120 | 170.272 | 11.63 | 7.17 | 170.283 | 14.00 | 9.84 | 170.283 |

| 24,01 | .9453 | - | 226 | - | 130 | 170.274 | 11.63 | 7.17 | 170.283 | 14.13 | 10.00 | 170.283 | |||

| 24,50 | .9646 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 11.88 | 7.17 | 170.283 | 14.38 | 10.00 | 170.283 |

| 25,00 | .9843 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 12.25 | 7.08 | 170.283 | 14.50 | 10.11 | 170.283 |

| 25,50 | 10.039 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 12.50 | 7.72 | 170.283 | 14.75 | 10.31 | 170.283 |

| 26,00 | 10.236 | 174 | - | 78 | 170.274 | 226 | - | 130 | 170.274 | 12.50 | 7.72 | 170.283 | 15.13 | 10.63 | 170.283 |

| 26,01 | 10.240 | - | 238 | - | 140 | 170.274 | 12.50 | 7.72 | 170.283 | 15.50 | 10.94 | 170.283 | |||

| 26,50 | 10.433 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 13.13 | 8.27 | 170.284 | 15.75 | 11.25 | 170.284 |

| 27,00 | 10.630 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 13.13 | 8.27 | 170.284 | 16.13 | 11.56 | 170.284 |

| 27,50 | 10.827 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 13.75 | 8.82 | 170.284 | 16.50 | 11.88 | 170.284 |

| 28,00 | 11.024 | 182 | - | 84 | 170.274 | 238 | - | 140 | 170.274 | 13.75 | 8.82 | 170.284 | 16.88 | 12.19 | 170.284 |

| 28,02 | 11.028 | - | 250 | - | 150 | 170.276 | 13.75 | 8.82 | 170.284 | 17.13 | 12.50 | 170.284 | |||

| 28,50 | 11.220 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | 14.25 | 8.82 | 170.284 | 17.63 | 12.50 | 170.284 |

| 29,00 | 11.417 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | ||||||

| 29,50 | 11.614 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | ||||||

| 30,00 | 11.811 | 190 | - | 90 | 170.276 | 250 | - | 150 | 170.276 | ||||||

| 30,01 | 11.815 | - | 264 | - | 160 | 170.276 | |||||||||

| 30,50 | 12.008 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | ||||||

| 31,00 | 12.205 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | ||||||

| 31,50 | 12.402 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | ||||||

| 32,00 | 12.598 | 200 | - | 96 | 170.276 | 264 | - | 160 | 170.276 | ||||||

| 32,01 | 12.602 | 220 | 159 | 99 | 170.276 | 293 | 225 | 165 | 170.277 | ||||||

| 33,00 | 12.992 | 227 | 159 | 99 | 170.276 | 293 | 225 | 165 | 170.277 | ||||||

| 34,00 | 13.386 | 225 | 157 | 102 | 170.276 | 293 | 225 | 170 | 170.277 | ||||||

| 35,00 | 13.780 | 235 | 167 | 105 | 170.276 | 305 | 237 | 175 | 170.277 | ||||||

| 36,00 | 14.173 | 233 | 165 | 108 | 170.276 | 305 | 237 | 180 | 170.277 | ||||||

| 36,01 | 14.177 | 237 | 176 | 111 | 170.276 | 318 | 250 | 185 | 170.277 | ||||||

| 37,00 | 14.567 | 244 | 176 | 111 | 170.276 | 318 | 250 | 185 | 170.277 | ||||||

| 38,00 | 14.961 | 242 | 174 | 114 | 170.276 | 318 | 250 | 190 | 170.277 | ||||||

| 39,00 | 15.354 | 252 | 184 | 117 | 170.276 | 330 | 262 | 195 | 170.277 | ||||||

| 40,00 | 15.748 | 250 | 182 | 120 | 170.276 | 330 | 262 | 200 | 170.277 | ||||||

| D1 | 5 x D | 8 x D | |||||

| mm | in | L1 | L4 max | wrench | L1 | L4 max | wrench |

| 12,700 | .5000 | 3.94 | 2.50 | 170.294 | — | — | — |

| 12,929 | .5090 | 4.00 | 2.55 | 170.294 | — | — | — |

| 13,106 | .5160 | 4.00 | 2.58 | 170.294 | — | — | — |

| 13,487 | .5310 | 4.13 | 2.66 | 170.294 | — | — | — |

| 13,894 | .5470 | 4.13 | 2.73 | 170.289 | — | — | — |

| 14,300 | .5630 | 4.25 | 2.81 | 170.289 | — | — | — |

| 14,681 | .5780 | 4.31 | 2.89 | 170.289 | — | — | — |

| 15,088 | .5940 | 4.38 | 2.97 | 170.289 | — | — | — |

| 15,469 | .6090 | 4.5 | 3.05 | 170.289 | — | — | — |

| 15,875 | .6250 | 4.75 | 3.15 | 170.270 | 6.25 | 5.00 | 170.271 |

| 17,463 | .6875 | 5.25 | 3.54 | 170.270 | 7.00 | 5.50 | 170.271 |

| 19,050 | .7500 | 5.88 | 3.94 | 170.271 | 7.50 | 6.00 | 170.281 |

| 19,050 | .7500 | 6.00 | 3.94 | 170.271 | 7.50 | 6.00 | 170.281 |

| 20,637 | .8125 | 6.25 | 4.33 | 170.273 | 8.00 | 6.50 | 170.282 |

| 20,638 | .8125 | 6.25 | 4.33 | 170.273 | — | — | 170.282 |

| 22,225 | .8750 | 6.63 | 4.72 | 170.273 | 8.50 | 7.00 | 170.282 |

| 22,225 | .8750 | 6.75 | 4.72 | 170.273 | 8.50 | 7.00 | 170.282 |

| 23,813 | .9375 | 6.63 | 4.72 | 170.273 | 9.13 | 7.50 | 170.282 |

| 24,606 | .9688 | 7.13 | 5.12 | 170.275 | — | — | — |

| 25,003 | .9844 | 7.13 | 5.12 | 170.275 | 9.50 | 7.88 | 170.283 |

| 25,400 | 1.0000 | 7.25 | 5.12 | 170.275 | 9.63 | 8.00 | 170.283 |

| 25,400 | 1.0000 | 7.25 | 5.12 | 170.275 | 9.63 | 8.00 | 170.283 |

| 26,988 | 1.0625 | 7.63 | 5.51 | 170.275 | 10.25 | 8.50 | 170.283 |

| 28,575 | 1.1250 | 8.13 | 5.91 | 170.277 | 10.75 | 9.00 | 170.284 |

| 30,163 | 1.1875 | 8.50 | 6.30 | 170.277 | 11.38 | 9.50 | 170.284 |

| 31,750 | 1.2500 | 8.50 | 6.30 | 170.277 | 11.88 | 10.00 | 170.284 |

| 31,750 | 1.2500 | 8.75 | 6.30 | 170.277 | 11.88 | 10.00 | 170.284 |