欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称: {{SolutionName}}- 产品

- /

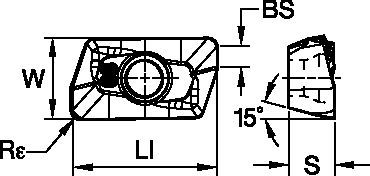

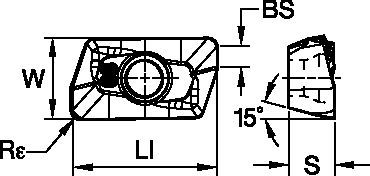

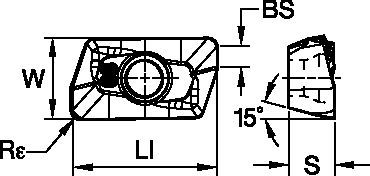

- Inserts for Mill 1-10™ • EDCT-LD • Metric

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

Inserts for Mill 1-10™ • EDCT-LD • Metric

可转位刀片

Features and benefits

- 精加工及高精度加工性能

- 轻型加工

- 15° 正前角

- 高精度的刀片底面

- Ap1最大值 10mm (0.393英寸)

刀片选择指南

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | – | (Stabile Geometrie) | |||

| – | Verschleiß- festigkeit |  <="" td=""> <="" td=""> | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | .E..LD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .E..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| M1–M2 | .E..LD | KCSM40 | .S..GD | KC725M | .E..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCPM40 | .E..HD | KCSM40 |

| K1–K2 | .E..LD | KCK15 | .S..GD | KCK15 | .E..HD | KCK15 |

| K3 | .E..LD | KC520M | .S..GD | KC520M | .E..HD | KC520M |

| N1–N2 | .F..LDJ | KC410M | .E..LDJ | KC422M | .E..LD | KC510M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| H1 | .E..LD | KC510M | – | – | – | – |

推荐初始进给率 [mm]

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 | .F..LDJ |

| .F..-PCD | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 | .F..-PCD |

| .E..LDJ | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,32 | 0,06 | 0,16 | 0,28 | 0,05 | 0,15 | 0,25 | .E..LDJ |

| .E..LD | 0,12 | 0,35 | 0,57 | 0,09 | 0,25 | 0,41 | 0,07 | 0,19 | 0,31 | 0,06 | 0,17 | 0,27 | 0,05 | 0,15 | 0,25 | .E..LD |

| .S..GE | 0,23 | 0,46 | 0,70 | 0,17 | 0,33 | 0,51 | 0,13 | 0,25 | 0,38 | 0,11 | 0,22 | 0,33 | 0,10 | 0,20 | 0,30 | .S..GE |

| .S..GD | 0,23 | 0,47 | 0,71 | 0,17 | 0,34 | 0,51 | 0,13 | 0,25 | 0,38 | 0,11 | 0,22 | 0,33 | 0,10 | 0,20 | 0,30 | .S..GD |

| .E..HD | 0,23 | 0,51 | 0,82 | 0,17 | 0,37 | 0,59 | 0,13 | 0,28 | 0,44 | 0,11 | 0,24 | 0,38 | 0,10 | 0,22 | 0,35 | .E..HD |

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..LDJ | .003 | .005 | .009 | .003 | .004 | .007 | .002 | .003 | .006 | .002 | .003 | .006 | .002 | .003 | .006 | .F..LDJ |

| .E..LDJ | .003 | .007 | .012 | .003 | .005 | .009 | .002 | .005 | .008 | .002 | .004 | .007 | .002 | .004 | .007 | .E..LDJ |

| .E..LD | .004 | .007 | .012 | .003 | .005 | .009 | .002 | .005 | .008 | .002 | .004 | .007 | .002 | .004 | .007 | .E..LD |

| .S..GE | .007 | .008 | .014 | .005 | .006 | .010 | .004 | .005 | .009 | .004 | .005 | .008 | .004 | .005 | .008 | .S..GE |

| .S..GD | .007 | .008 | .014 | .005 | .006 | .010 | .004 | .005 | .009 | .004 | .005 | .008 | .004 | .005 | .008 | .S..GD |

| .E..HD | .007 | .010 | .015 | .005 | .008 | .011 | .004 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .009 | .E..HD |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

推荐初始速度 [m/min]

| Werkstoffgruppe | K313 | KC410M | KC422M | KC510M | KC520M | KC522M | KC725M | KCK15 | KCPM20 | KCPK30 | |||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | 550 | 485 | 450 | 455 | 395 | 370 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | 340 | 310 | 275 | 280 | 255 | 230 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | 310 | 275 | 255 | 255 | 230 | 205 | |

| 4 | – | – | – | – | – | – | – | – | – | 245 | 200 | 170 | – | – | – | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | 230 | 215 | 190 | 190 | 175 | 160 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | 275 | 250 | 230 | 260 | 230 | 210 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | 190 | 170 | 145 | 160 | 135 | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | 225 | 200 | 175 | 205 | 185 | 155 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | 205 | 175 | 160 | 185 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | 160 | 145 | 125 | 145 | 130 | 115 | |

| K | 1 | 190 | 170 | 150 | – | – | – | – | – | – | 295 | 265 | 240 | 270 | 245 | 215 | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 360 | 325 | 295 | 295 | 265 | 240 |

| 2 | – | – | – | – | – | – | – | – | – | 230 | 205 | 190 | 210 | 190 | 175 | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 285 | 255 | 235 | 235 | 210 | 190 | |

| 3 | – | – | – | – | – | – | – | – | – | 195 | 175 | 160 | 175 | 160 | 145 | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 240 | 215 | 200 | 195 | 175 | 160 | |

| N | 1–2 | 795 | 695 | 600 | 1215 | 1080 | 995 | 1075 | 945 | 875 | 640 | 570 | 525 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 70 | 50 | 35 | 60 | 45 | 30 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | K313 | KC410M | KC422M | KC510M | KC520M | KC522M | KC725M | KCK15 | KCPM20 | KCPK30 | |||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 1080 | 940 | 880 | 860 | 750 | 700 | – | – | – | 1810 | 1590 | 1470 | 1485 | 1300 | 1210 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 900 | 790 | 660 | 720 | 630 | 530 | – | – | – | 1120 | 1010 | 910 | 920 | 830 | 750 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 830 | 700 | 580 | 660 | 560 | 460 | – | – | – | 1010 | 910 | 830 | 830 | 750 | 680 | |

| 4 | – | – | – | – | – | – | – | – | – | 800 | 650 | 550 | – | – | – | 740 | 610 | 490 | 590 | 490 | 390 | – | – | – | 760 | 700 | 630 | 620 | 575 | 520 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 610 | 550 | 490 | 490 | 440 | 390 | – | – | – | 910 | 820 | 750 | 850 | 760 | 690 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 540 | 410 | 330 | 430 | 330 | 260 | – | – | – | 630 | 550 | 475 | 520 | 450 | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 670 | 590 | 540 | 560 | 490 | 450 | – | – | – | 730 | 655 | 570 | 680 | 600 | 515 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 610 | 520 | 430 | 510 | 430 | 360 | – | – | – | 670 | 580 | 520 | 610 | 530 | 460 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 460 | 400 | 310 | 380 | 330 | 260 | – | – | – | 530 | 475 | 410 | 475 | 430 | 380 | |

| K | 1 | 620 | 550 | 490 | – | – | – | – | – | – | 960 | 870 | 780 | 880 | 800 | 710 | 750 | 680 | 600 | – | – | – | 1380 | 1255 | 1115 | 1180 | 1070 | 960 | 965 | 875 | 780 |

| 2 | – | – | – | – | – | – | – | – | – | 760 | 680 | 630 | 690 | 620 | 580 | 590 | 530 | 490 | – | – | – | 1095 | 975 | 910 | 940 | 840 | 770 | 770 | 690 | 630 | |

| 3 | – | – | – | – | – | – | – | – | – | 640 | 570 | 520 | 580 | 520 | 470 | 490 | 440 | 400 | – | – | – | 920 | 815 | 750 | 790 | 700 | 650 | 645 | 575 | 530 | |

| N | 1–2 | 2610 | 2280 | 1960 | 3990 | 3550 | 3270 | 3520 | 3100 | 2870 | 2100 | 1870 | 1720 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | 3550 | 3270 | 3000 | 3100 | 2870 | 2500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 120 | 90 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 120 | 90 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 170 | 130 | 90 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 230 | 170 | 120 | 200 | 150 | 100 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |