Product Similar To :

FBX • Long • Taper Flange Mount

FBX • Long • Taper Flange Mount

Material Number7228294

ISO Catalog IDKSEMX6001FBX150BTF46MANSI Catalog IDKSEMX6001FBX150BTF46M

- P Steel

- M Stainless Steel

- S High-Temp Alloys

- .caption

Drilling

Drilling: Inclined Entry

Drilling: X-Offset

Drilling: Flat Bottom

Drilling: Convex

Plunge Milling

Counter Boring

Chain Drilling

Drilling: Half-Cylindrical Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 7228294 |

| ISO Catalog ID | KSEMX6001FBX150BTF46M |

| ANSI Catalog ID | KSEMX6001FBX150BTF46M |

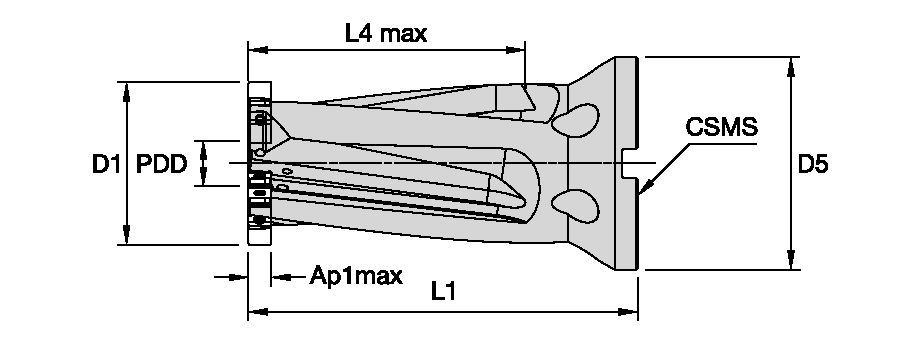

| [D1] Drill Diameter M | 60 mm |

| [D1] Drill Diameter M | 2.3622 in |

| [PDD] Pilot Drill Cut Diameter | 38 mm |

| [PDD] Pilot Drill Cut Diameter | 1.4961 in |

| [PPL] Pilot Protrusion Length | 0.2 mm |

| [PPL] Pilot Protrusion Length | 0.0079 in |

| [L1] Insert Gage Length | 215 mm |

| [L1] Insert Gage Length | 8.4646 in |

| [L4] Maximum Drilling Depth | 150 mm |

| [L4] Maximum Drilling Depth | 5.9055 in |

| [D5] Maximum Body Diameter | 117.475 mm |

| [D5] Maximum Body Diameter | 4.625 in |

| [SSC] Insert Seat Size | 10 |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

- .caption

Uses and application

Drilling

Drilling: Inclined Entry

Drilling: X-Offset

Drilling: Flat Bottom

Drilling: Convex

Plunge Milling

Counter Boring

Chain Drilling

Drilling: Half-Cylindrical Drilling

Features and benefits

- Advanced drill body design for flat bottom drilling and plunging

- Two effective cutting edges in the center for maximum feed

- Four effective cutting edges on the outer diameter for highest productivity on plunging operations

- Interchangeable coolant nozzles in different sizes for optimized heat control

- Four flutes for reliable chip evacuation and highest tool stiffness

- BTF taper flange connection for maximum stability and flexibility

- Use the pocket seat size SSC to select a suitable center insert

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use