Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Začněte rok 2024 s fenomenálními úsporami na vrtacích nástrojích.

Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Produkty

- /

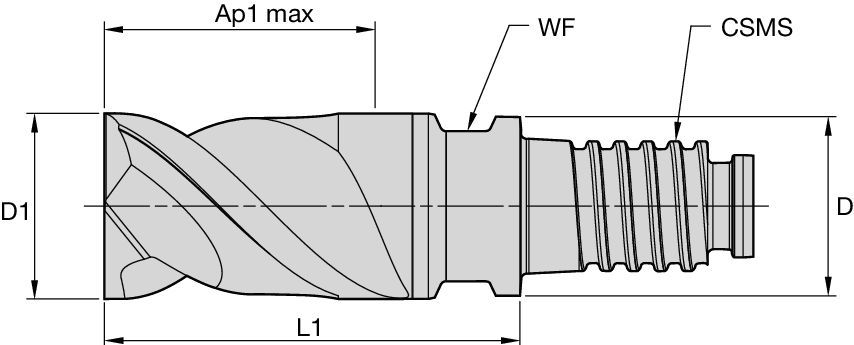

- DUO-LOCK™ • MaxiMet™ • Square End • 2 Flutes • Inch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

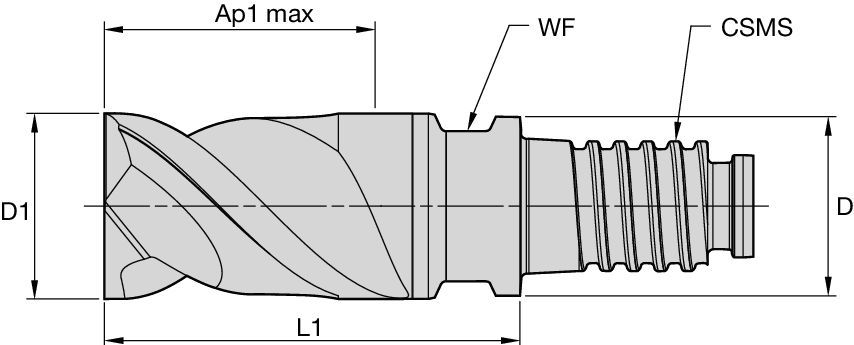

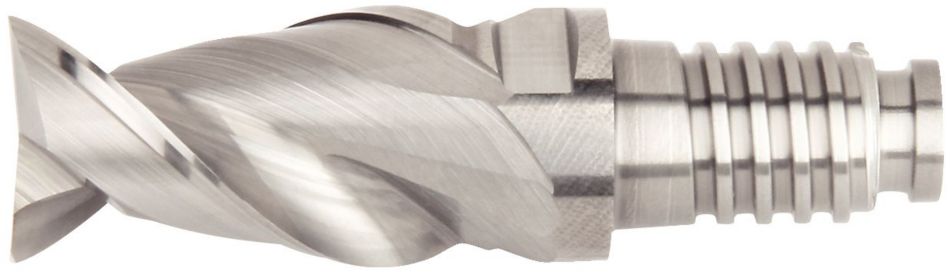

DUO-LOCK™ • MaxiMet™ • Square End • 2 Flutes • Inch

MaxiMet • ABDF • Wiper Facet

Vlastnosti a výhody

- Center cutting.

- Optimized for thin-wall applications.

- Wiper facet, special end gash, and flute geometry enable improved surface finishes.

- Standard items listed. Additional styles and coatings made-to-order.

Použití

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 2

Helix Angle: 45°

Corner Style: Square End

| End Mill Tolerances | |

| D1 | tolerance e8 |

| 13/32

|

-0,00126"/-0,00232" |

| 23/32

|

-0,00157"/-0,00287" |

|

|

-0,00197''/-0,00350'' |

MaxiMet • ABDF • Wiper Facet

| Material

|

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||

| Side Milling (A) and Slotting (B) | short | medium | long | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||

| A | B | adapter reach | D1

|

|||||||||||||||

| K600 | K600 | K600 | ||||||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

frac. | 3/8 | 1/2 | 5/8 | 3/4 | |||||||||||

| ap | ae | ap | Min | Max | Min | Max | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | |||||

| N | 1 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 6560 | 1312 | – | 3936 | 984 | – | 3936 | IPT | .0029 | .0038 | .0048 | .0057 |

| 2 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0023 | .0031 | .0038 | .0046 | |

| 3 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 4 | 1.5 x D | 0.3 x D | 1.0 x D | 1310 | – | 2460 | 1048 | – | 1476 | 786 | – | 1476 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 5 | 1.5 x D | 0.3 x D | 1.0 x D | 820 | – | 3280 | 656 | – | 1968 | 492 | – | 1968 | IPT | .0026 | .0034 | .0043 | .0052 | |

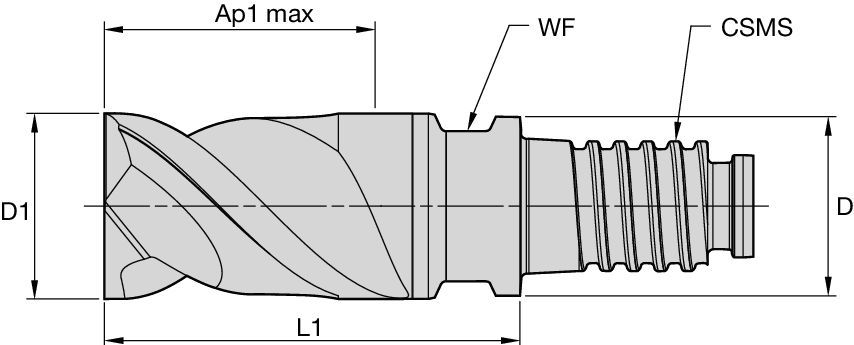

MaxiMet • ABDE • Wiper Facet • Unequal Flute Spacing

| Material

|

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||

| Side Milling (A) and Slotting (B) | short | medium | long | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||

| A | B | adapter reach | D1

|

|||||||||||||||

| K600 | K600 | K600 | ||||||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

frac. | 3/8 | 1/2 | 5/8 | 3/4 | |||||||||||

| ap | ae | ap | Min | Max | Min | Max | Min | Max | dec. | .375 | .500 | .6250 | .7500 | |||||

| N | 1 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 6560 | 1312 | – | 3936 | 984 | – | 3936 | IPT | .0029 | .0038 | .0048 | .0057 |

| 2 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0023 | .0031 | .0038 | .0046 | |

| 3 | 1.5 x D | 0.3 x D | 1.0 x D | 1640 | – | 4920 | 1312 | – | 2952 | 984 | – | 2952 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 4 | 1.5 x D | 0.3 x D | 1.0 x D | 1310 | – | 2460 | 1048 | – | 1476 | 786 | – | 1476 | IPT | .0020 | .0027 | .0033 | .0040 | |

| 5 | 1.5 x D | 0.3 x D | 1.0 x D | 820 | – | 3280 | 656 | – | 1968 | 492 | – | 1968 | IPT | .0026 | .0034 | .0043 | .0052 | |