Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Začněte rok 2024 s fenomenálními úsporami na vrtacích nástrojích.

Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Produkty

- /

- DUO-LOCK™ • KenCut™ CM • Multi-Flute • Inch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

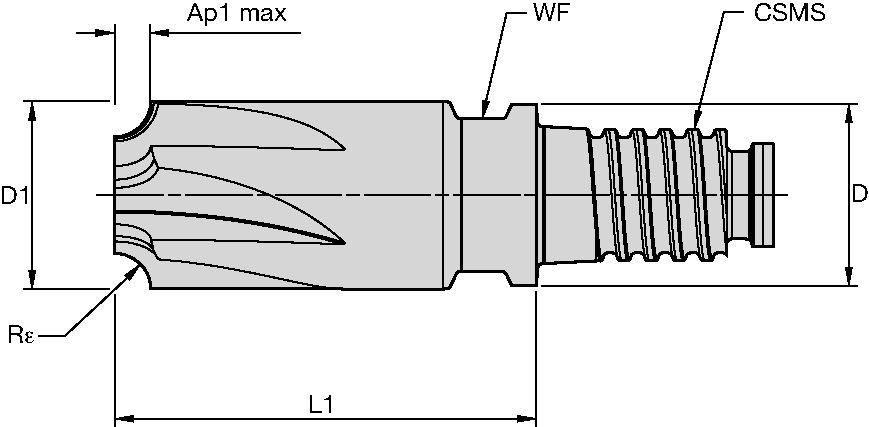

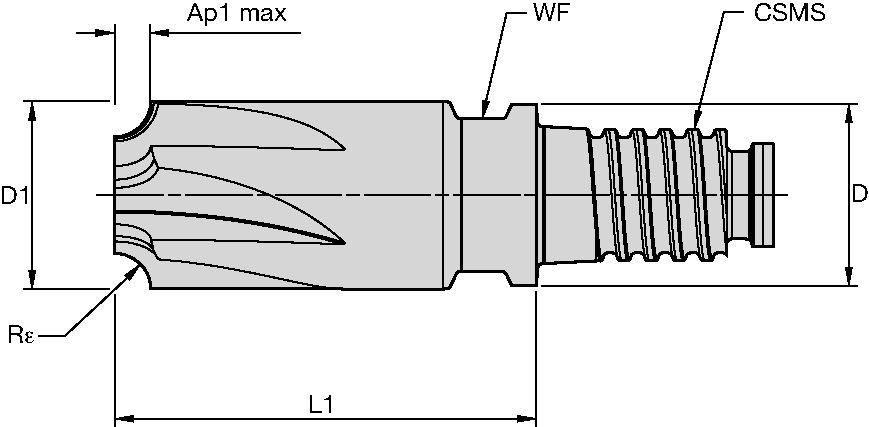

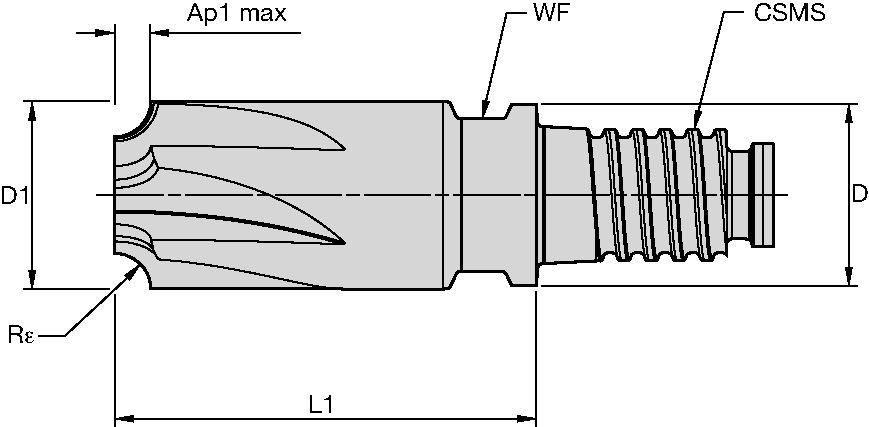

DUO-LOCK™ • KenCut™ CM • Multi-Flute • Inch

Modular End Milling • XRDA Style

Vlastnosti a výhody

- Non-center cutting.

- Standard items listed. Additional styles and coatings made-to-order.

Použití

Side/Shoulder Milling: Radius

Tool Dimensions: Flute Configuration: X (variable)

Helix Angle: 0°

| End Mill Tolerances | |

| D1 | tolerance e8 |

| 13/32

|

-0,00126"/-0,00232" |

| 23/32

|

-0,00157"/-0,00287" |

XRDA • Inch

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||||

| Corner Rounding | short | medium | long | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||

| A | adapter reach | D1

|

||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | ||||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

frac. | 3/8 | 1/2 | 5/8 | ||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | dec. | .375 | .500 | .625 | |||||

| P | 0 | 0.35 x D | 0.35 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0022 | .0027 | .0032 |

| 1 | 0.35 x D | 0.35 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0022 | .0027 | .0032 | |

| 2 | 0.35 x D | 0.35 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0022 | .0027 | .0032 | |

| 3 | 0.35 x D | 0.35 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0018 | .0023 | .0027 | |

| 4 | 0.35 x D | 0.35 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0016 | .0021 | .0024 | |

| 5 | 0.35 x D | 0.35 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0015 | .0018 | .0022 | |

| 6 | 0.35 x D | 0.35 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0012 | .0015 | .0018 | |

| M | 1 | 0.35 x D | 0.35 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0018 | .0023 | .0027 |

| 2 | 0.35 x D | 0.35 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0015 | .0018 | .0022 | |

| 3 | 0.35 x D | 0.35 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0012 | .0015 | .0018 | |

| K | 1 | 0.35 x D | 0.35 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0022 | .0027 | .0032 |

| 2 | 0.35 x D | 0.35 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0018 | .0023 | .0027 | |

| 3 | 0.35 x D | 0.35 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0015 | .0018 | .0022 | |

| N | 1 | 0.35 x D | 0.35 x D | 1640 | – | 6560 | 1312 | – | 5248 | 984 | – | 3936 | IPT | .0030 | .0040 | .0050 |

| 2 | 0.35 x D | 0.35 x D | 1640 | – | 4920 | 1312 | – | 3936 | 984 | – | 2952 | IPT | .0024 | .0032 | .0040 | |

| 3 | 0.35 x D | 0.35 x D | 1640 | – | 4920 | 1312 | – | 3936 | 984 | – | 2952 | IPT | .0021 | .0028 | .0035 | |

| 4 | 0.35 x D | 0.35 x D | 1310 | – | 2460 | 1048 | – | 1968 | 786 | – | 1476 | IPT | .0021 | .0028 | .0035 | |

| 5 | 0.35 x D | 0.35 x D | 820 | – | 3280 | 656 | – | 2624 | 492 | – | 1968 | IPT | .0027 | .0036 | .0045 | |

| 6 | 0.35 x D | 0.35 x D | 330 | – | 2460 | 264 | – | 1968 | 198 | – | 1476 | IPT | .0030 | .0040 | .0050 | |

| 7 | 0.35 x D | 0.35 x D | 330 | – | 2460 | 264 | – | 1968 | 198 | – | 1476 | IPT | .0021 | .0028 | .0035 | |

| S | 1 | 0.35 x D | 0.35 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0018 | .0023 | .0027 |

| 2 | 0.35 x D | 0.35 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0012 | .0015 | |

| 3 | 0.35 x D | 0.35 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0012 | .0015 | |

| 4 | 0.35 x D | 0.35 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0013 | .0017 | .0020 | |

| H | 1 | 0.35 x D | 0.35 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0016 | .0021 | .0024 |