Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Začněte rok 2024 s fenomenálními úsporami na vrtacích nástrojích.

Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Produkty

- /

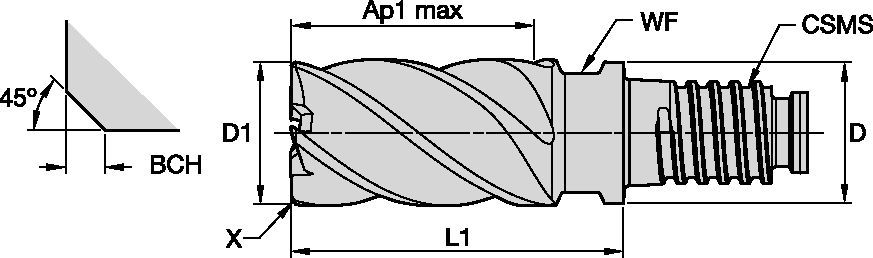

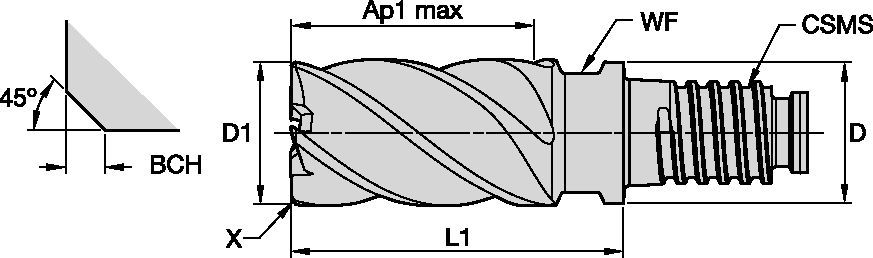

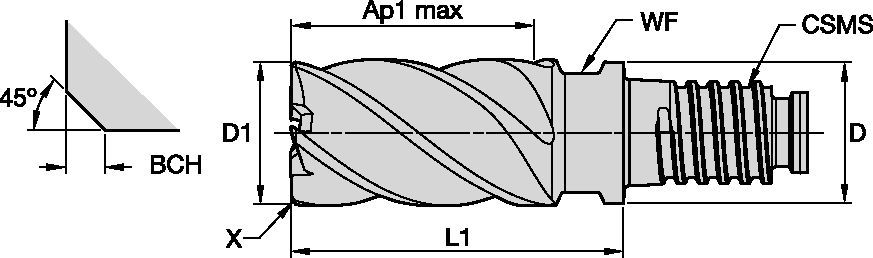

- DUO-LOCK™ • HARVI™ II • S rohovým sražením • 5-břité • Metrické

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

DUO-LOCK™ • HARVI™ II • S rohovým sražením • 5-břité • Metrické

Modulární stopkové frézy • UCDV

Vlastnosti a výhody

- Modulární stopkové frézy pro hrubování a dokončování ocelí a nerezových ocelí.

- Nelze zavrtávat v ose z.

- Technologie asymetrické geometrie břitu a proměnné šroubovice minimalizuje chvění a harmonické frekvence pro plynulejší obrábění.

- Zavrtávání až do 3°.

- Drážkování až do 1 x D.

Použití

Corner Style: Corner Chamfer

Helix Angle: 37°/39°

Ramping: 3°

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

| End Mill Tolerances | |

| D1 | tolerance e8 |

|

|

-0,032/-0,059 |

|

|

-0,040/-0,073 |

|

|

-0,050/-0,089 |

HARVI II • UCDV • Asymetrická geometrie břitu

| Material

|

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> | short | medium | long | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | |||||||||||||||

| A | B | adapter reach | D1

|

||||||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | |||||||||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

|||||||||||||||||||

| UCDV | UDDV | ap | ae | ap | Min | Max | Min | Max | Min | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | 32,0 | ||||

| P | 0 |

|

1,5 x D | 0,5 x D | 1 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 |

| 1 |

|

1,5 x D | 0,5 x D | 1 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 | |

| 2 |

|

1,5 x D | 0,5 x D | 1 x D | 140 | – | 190 | 126 | – | 171 | 126 | – | 171 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 | |

| 3 |

|

1,5 x D | 0,5 x D | 1 x D | 120 | – | 160 | 108 | – | 144 | 108 | – | 144 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 | |

| 4 |

|

1,5 x D | 0,4 x D | 0,75 x D | 90 | – | 150 | 81 | – | 135 | 81 | – | 135 | fz | 0,046 | 0,053 | 0,065 | 0,075 | 0,083 | 0,087 | |

| 5 | 5 | 1,5 x D | 0,4 x D | 1 x D | 60 | – | 100 | 51 | – | 85 | 48 | – | 80 | fz | 0,041 | 0,048 | 0,059 | 0,069 | 0,077 | 0,084 | |

| 6 | 6 | 1,5 x D | 0,4 x D | 0,75 x D | 50 | – | 75 | 42,5 | – | 63,75 | 40 | – | 60 | fz | 0,034 | 0,040 | 0,048 | 0,055 | 0,060 | 0,062 | |

| M | 1 |

|

1,5 x D | 0,4 x D | 1 x D | 90 | – | 115 | 72 | – | 92 | 63 | – | 80,5 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 |

| 2 |

|

1,5 x D | 0,4 x D | 1 x D | 60 | – | 80 | 48 | – | 64 | 42 | – | 56 | fz | 0,041 | 0,048 | 0,059 | 0,069 | 0,077 | 0,084 | |

| 3 |

|

1,5 x D | 0,4 x D | 1 x D | 60 | – | 70 | 48 | – | 56 | 42 | – | 49 | fz | 0,034 | 0,040 | 0,048 | 0,055 | 0,060 | 0,062 | |

| K | 1 |

|

1,5 x D | 0,5 x D | 1 x D | 120 | – | 150 | 108 | – | 135 | 108 | – | 135 | fz | 0,061 | 0,070 | 0,086 | 0,097 | 0,105 | 0,106 |

| 2 |

|

1,5 x D | 0,5 x D | 1 x D | 110 | – | 140 | 99 | – | 126 | 99 | – | 126 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 | |

| 3 |

|

1,5 x D | 0,5 x D | 1 x D | 110 | – | 130 | 99 | – | 117 | 99 | – | 117 | fz | 0,041 | 0,048 | 0,059 | 0,069 | 0,077 | 0,084 | |

| S | 1 | 1 | 1,5 x D | 0,3 x D | 0,3 x D | 50 | – | 90 | 40 | – | 72 | 30 | – | 54 | fz | 0,051 | 0,060 | 0,074 | 0,086 | 0,097 | 0,105 |

| 2 | 2 | 1,5 x D | 0,3 x D | 0,3 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,027 | 0,032 | 0,039 | 0,046 | 0,052 | 0,057 | |

| 3 | 3 | 1,5 x D | 0,3 x D | 0,3 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,027 | 0,032 | 0,039 | 0,046 | 0,052 | 0,057 | |

| 4 | 4 | 1,5 x D | 0,4 x D | 1 x D | 50 | – | 60 | 40 | – | 48 | 30 | – | 36 | fz | 0,038 | 0,044 | 0,055 | 0,063 | 0,071 | 0,077 | |

| H | 1 | 1 | 1,5 x D | 0,4 x D | 0,75 x D | 80 | – | 140 | 64 | – | 112 | 48 | – | 84 | fz | 0,046 | 0,053 | 0,065 | 0,075 | 0,083 | 0,087 |

| 2 | 2 | 1,5 x D | 0,2 x D | 0,5 x D | 70 | – | 120 | 56 | – | 96 | 42 | – | 72 | fz | 0,034 | 0,040 | 0,048 | 0,055 | 0,060 | 0,062 | |