Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Začněte rok 2024 s fenomenálními úsporami na vrtacích nástrojích.

Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Produkty

- /

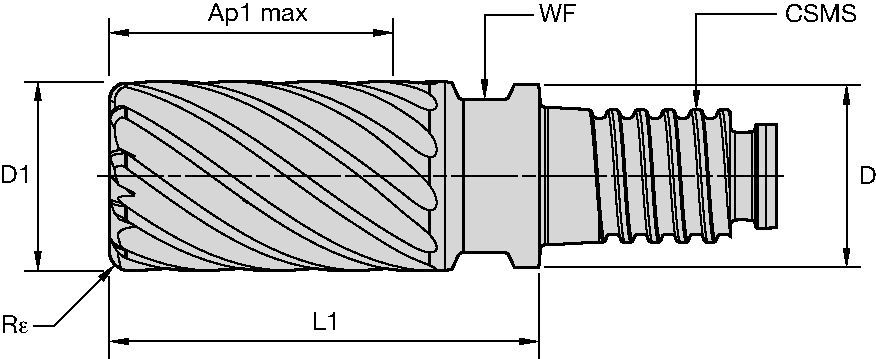

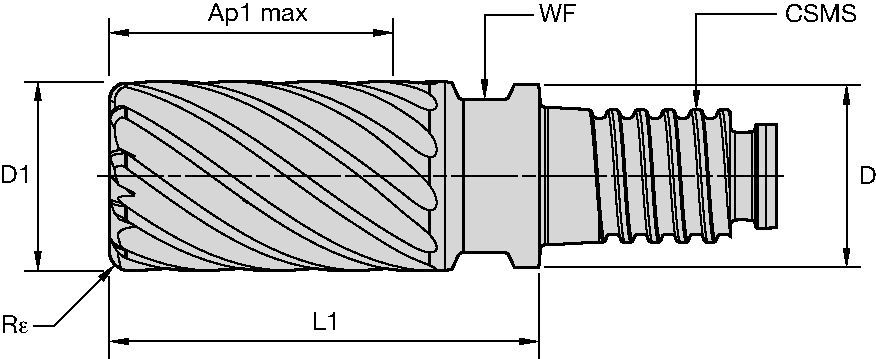

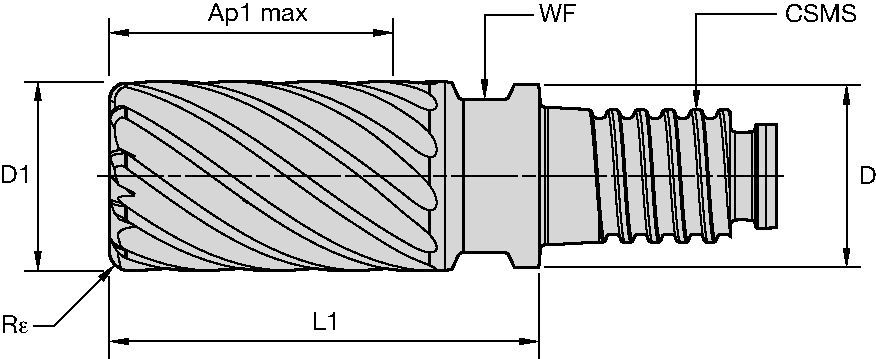

- DUO-LOCK™ • RSM II™ • Dokončovací • S rohovým rádiusem • Vícebřité • Metrické

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

DUO-LOCK™ • RSM II™ • Dokončovací • S rohovým rádiusem • Vícebřité • Metrické

Modulární stopkové frézy • FSDE

Vlastnosti a výhody

- Modulární stopkové frézy pro vysoce výkonné dokončování žáruvzdorných slitin.

- Nelze zavrtávat v ose z.

- Asymetrická geometrie břitu minimalizuje chvění a zajišťuje lepší výsledky obrábění.

Použití

Helix Angle: 36°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: X (variable)

Corner Style: Corner Radius

Side Milling/Shoulder Milling: Fine Finishing

| End Mill Tolerances | |

| D1 | tolerance e8 |

|

|

-0,032/-0,059 |

|

|

-0,040/-0,073 |

|

|

-0,050/-0,089 |

FSDE • Metrické

| Material

|

<="" td=""> <="" td=""> | short | medium | long | Recommended feed per tooth (fz = mm/th) for side milling (A). | |||||||||||||

| A | adapter reach | D1

|

||||||||||||||||

| KC643M | KC643M | KC643M | ||||||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

||||||||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | |||||

| P | 4 | 1,5 x D | 0,2

|

135 | – | 495 | 122 | – | 446 | 122 | – | 446 | fz | 0,120 | 0,129 | 0,149 | 0,163 | 0,166 |

| 5 | 1,5 x D | 0,2

|

90 | – | 330 | 77 | – | 281 | 72 | – | 264 | fz | 0,108 | 0,116 | 0,135 | 0,150 | 0,155 | |

| M | 1 | 1,5 x D | 0,2

|

135 | – | 379,5 | 108 | – | 304 | 95 | – | 266 | fz | 0,135 | 0,145 | 0,169 | 0,187 | 0,193 |

| 2 | 1,5 x D | 0,2

|

90 | – | 264 | 72 | – | 211 | 63 | – | 185 | fz | 0,108 | 0,116 | 0,135 | 0,150 | 0,155 | |

| 3 | 1,5 x D | 0,2

|

90 | – | 231 | 72 | – | 185 | 63 | – | 162 | fz | 0,090 | 0,096 | 0,110 | 0,120 | 0,121 | |

| S | 1 | 1,5 x D | 0,2

|

75 | – | 297 | 60 | – | 238 | 45 | – | 178 | fz | 0,135 | 0,145 | 0,169 | 0,187 | 0,193 |

| 2 | 1,5 x D | 0,2

|

37,5 | – | 132 | 30 | – | 106 | 23 | – | 79 | fz | 0,071 | 0,077 | 0,090 | 0,100 | 0,104 | |

| 3 | 1,5 x D | 0,2

|

37,5 | – | 132 | 30 | – | 106 | 23 | – | 79 | fz | 0,071 | 0,077 | 0,090 | 0,100 | 0,104 | |

| 4 | 1,5 x D | 0,2

|

75 | – | 198 | 60 | – | 158 | 45 | – | 119 | fz | 0,099 | 0,107 | 0,124 | 0,138 | 0,142 | |

| H | 1 | 1,5 x D | 0,2

|

120 | – | 462 | 96 | – | 370 | 72 | – | 277 | fz | 0,120 | 0,129 | 0,149 | 0,163 | 0,166 |

| 2 | 1,5 x D | 0,2

|

105 | – | 396 | 84 | – | 317 | 63 | – | 238 | fz | 0,090 | 0,096 | 0,110 | 0,120 | 0,121 | |