Produkt podobný k:

CNMM-RH

Břitové destičky Kenloc™

Objednací číslo3755632

ISO katalogové IDCNMM250924RHANSI katalogové IDCNMM866RH

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 3755632 |

| ISO katalogové ID | CNMM250924RH |

| ANSI katalogové ID | CNMM866RH |

| Grade | KCP25 |

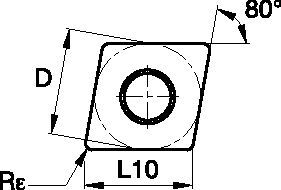

| [D] Insert IC Size | 25.4 mm |

| [D] Insert IC Size | 1 in |

| [L10] Insert Cutting Edge Length | 25.792 mm |

| [L10] Insert Cutting Edge Length | 1.015 in |

| [S] Insert Thickness | 9.525 mm |

| [S] Insert Thickness | .375 in |

| [Rε] Corner Radius | 2.4 mm |

| [Rε] Corner Radius | .0937 in |

| [D1] Insert Hole Size | 9.12 mm |

| [D1] Insert Hole Size | .3594 in |

Materiály obrobků

- Steel

- Cast Iron

Vlastnosti a výhody

- Velmi pevná řezná hrana pro velmi těžké hrubování nebo náročné přerušované řezy.

- Včetně sort Beyond™ Drive™.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use