Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto Konto ändern

Lieferadresse Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

Notifications

Mark all as read- Passwort ändern

- Mein Profil

- Abmelden

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Mehr fräsern, weniger zahlen – mit unseren zeitlich begrenzten Angeboten. Jetzt bestellen.

Kennametal steht Ihnen zur Diensten

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname:{{SolutionName}}- Produkte

- /

- Metallbearbeitungswerkzeuge

- /

- Fräsen

- /

- Vollhartmetall-Schaftfräsen

- /

- Hochleistungs-Vollhartmetall-Schaftfräser

- /

- KOR5™ • Vollhartmetall-Hochleistungsschaftfräser

- /

- KOR5 DS

- /

- KOR5™ DS • Abgerundet • 5 Spannuten • 5 x D • Glatter Schaft • Metrisch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

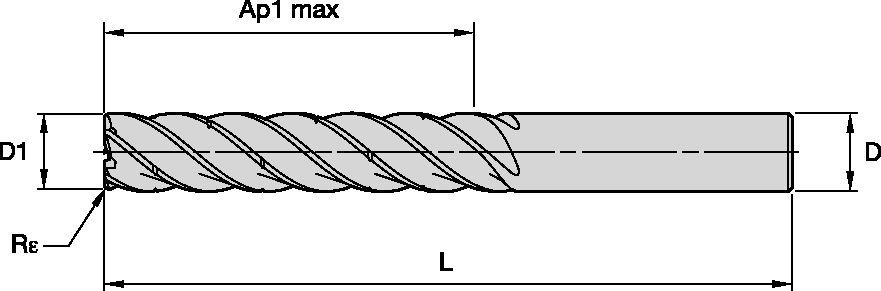

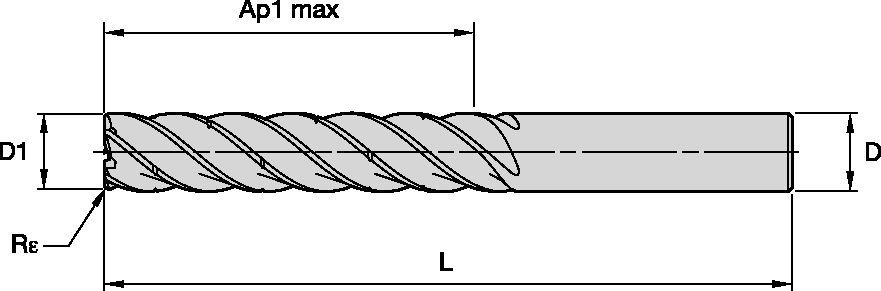

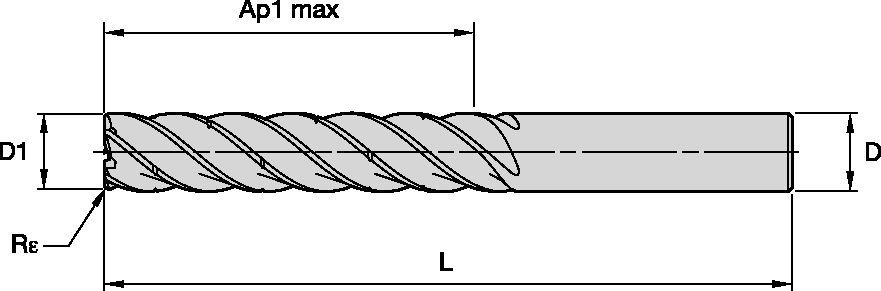

KOR5™ DS • Abgerundet • 5 Spannuten • 5 x D • Glatter Schaft • Metrisch

KOR5™ DS Vollhartmetall-Schaftfräser zum dynamischen Fräsen von Stahl und Edelstahl

Features and benefits

- Konzipiert für trochoidales Fräsen mit geringem radialen Eingriff und voller Fräslänge.

- Mit Spanformern für ideale Spanabführung bei hoher Oberflächenqualität.

- Die spezielle Spannutform reduziert Vibrationen und verbessert die Standzeit des Werkzeugs.

- Maßgeschneiderter Spiralwinkel zur Minimierung von Vibrationen und Optimierung der Werkzeugstandzeit.

- Die Stirnseitengeometrie wurde für maximale Standzeiten bei schraubenförmigen und rampenförmigen Bearbeitungen entwickelt.

Uses and application

Trochoidal Milling

Schräg-Eintauchfräsen 5°

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Werkzeugabmessungen: Schneidreihen: 5

Zylinderschaft – ohne Spannfläche

Spiralwinkel: 40°

Schneideckenausführung: Eckenradius

KOR5™ DS • 5 Spannuten • 5 x D • Tabelle mit den Anpassungsfaktoren für die Vorschubberechnung • Metrisch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | |

| Speed factor | Kv | 2.00 | 1.97 | 1.93 | 1.38 | 1.03 | 1.00 |

| Feed factor | KFz | 1.27 | 1.18 | 1.14 | 1.09 | 1.05 | 1.00 |

KOR5™ DS • 5 Spannuten • 5 x D • Anwendungsdaten • Metrisch

| Material |  | KC643M | Recommended feed per tooth (fz = mm/th) for side milling (A). | ||||||||||

| A | Cutting Speed | D1 | |||||||||||

| ap | ae | min | max | mm | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | |||

| P | 0 | 5 x D | 0,05 x D | 150 | – | 540 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 |

| 1 | 5 x D | 0,05 x D | 150 | – | 540 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 | |

| 2 | 5 x D | 0,05 x D | 140 | – | 513 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 | |

| 3 | 5 x D | 0,05 x D | 120 | – | 432 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 | |

| 4 | 5 x D | 0,05 x D | 90 | – | 405 | fz | 0,073 | 0,087 | 0,101 | 0,124 | 0,143 | 0,158 | |

| 5 | 5 x D | 0,05 x D | 60 | – | 270 | fz | 0,065 | 0,078 | 0,091 | 0,113 | 0,131 | 0,147 | |

| 6 | 5 x D | 0,05 x D | 50 | – | 202,5 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,105 | 0,115 | |

| M | 1 | 5 x D | 0,05 x D | 90 | – | 310,5 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 |

| 2 | 5 x D | 0,05 x D | 60 | – | 216 | fz | 0,065 | 0,078 | 0,091 | 0,113 | 0,131 | 0,147 | |

| 3 | 5 x D | 0,05 x D | 60 | – | 189 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,105 | 0,115 | |

| K | 1 | 5 x D | 0,05 x D | 120 | – | 405 | fz | 0,097 | 0,117 | 0,134 | 0,163 | 0,185 | 0,200 |

| 2 | 5 x D | 0,05 x D | 110 | – | 378 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 | |

| 3 | 5 x D | 0,05 x D | 110 | – | 351 | fz | 0,065 | 0,078 | 0,091 | 0,113 | 0,131 | 0,147 | |

| S | 1 | 5 x D | 0,05 x D | 50 | – | 243 | fz | 0,081 | 0,098 | 0,114 | 0,141 | 0,164 | 0,184 |

| 2 | 5 x D | 0,05 x D | 25 | – | 108 | fz | 0,043 | 0,052 | 0,060 | 0,075 | 0,087 | 0,099 | |

| 3 | 5 x D | 0,05 x D | 25 | – | 108 | fz | 0,043 | 0,052 | 0,060 | 0,075 | 0,087 | 0,099 | |

| 4 | 5 x D | 0,05 x D | 50 | – | 162 | fz | 0,060 | 0,072 | 0,084 | 0,104 | 0,120 | 0,135 | |

| H | 1 | 5 x D | 0,05 x D | 80 | – | 378 | fz | 0,073 | 0,087 | 0,101 | 0,124 | 0,143 | 0,158 |

| 2 | 5 x D | 0,05 x D | 70 | – | 324 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,105 | 0,115 | |

KOR™5DS

KOR™ Series End Mills: Solid End Mills for Dynamic Milling