Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Beginnen Sie das Jahr 2024 mit phänomenalen Einsparungen bei Bohrwerkzeugen.

Jetzt bestellen.

Kennametal steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

- KOR6™ DT • Abgerundet • 6 Spannuten • 3 x D • Safe-Lock™-Schaft • Metrisch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

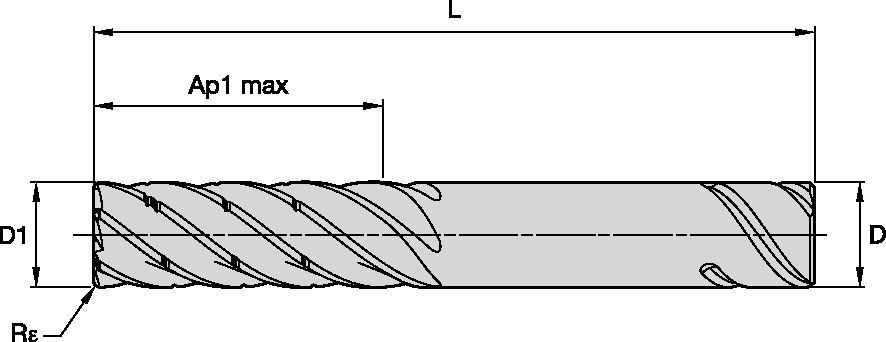

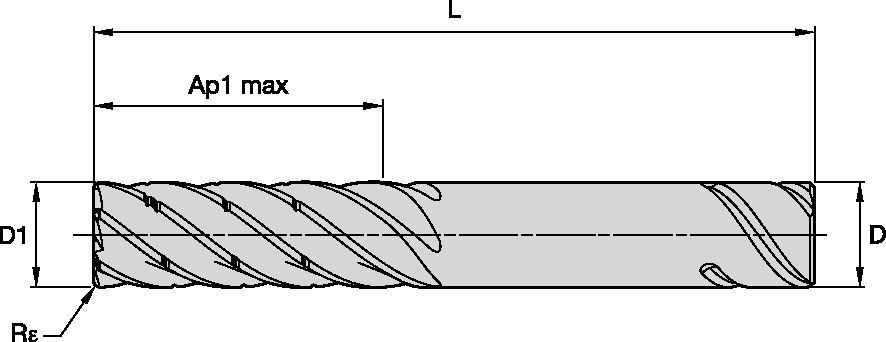

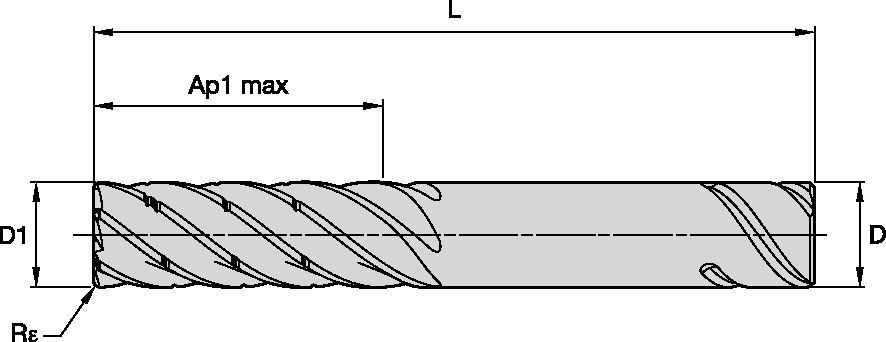

KOR6™ DT • Abgerundet • 6 Spannuten • 3 x D • Safe-Lock™-Schaft • Metrisch

KOR6™ DT Vollhartmetall-Schaftfräser zum dynamischen Fräsen von Titan

Features and benefits

- Konzipiert für trochoidales Fräsen mit geringem radialen Eingriff und voller Fräslänge.

- Mit Spanteilern für eine ideale Spanabführung.

- Die spezielle Spannutform reduziert Vibrationen und verbessert die Standzeit des Werkzeugs.

- Maßgeschneiderter Spiralwinkel zur Minimierung von Vibrationen und Optimierung der Werkzeugstandzeit.

- Die Stirnseitengeometrie wurde für maximale Standzeiten bei schraubenförmigen und rampenförmigen Bearbeitungen entwickelt.

- Safe-Lock zum Herausziehen.

- Zentrales Schneiden für Eintauch- und Rampenarbeiten.

Uses and application

Trochoidal Milling

Schräg-Eintauchfräsen Ins Volle

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Werkzeugabmessungen: Schneidreihen: 6

Spiralwinkel: 38°

Schneideckenausführung: Eckenradius

SAFE-LOCK Shank

KOR6™ DT • 6 Spannuten • 3 x D • Tabelle mit den Anpassungsfaktoren für die Vorschubberechnung • Metrisch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | |

| Speed factor | Kv | 2.15 | 2.11 | 2.07 | 1.48 | 1.11 | 1.07 | 1.04 | 1.00 |

| Feed factor | KFz | 1.65 | 1.53 | 1.47 | 1.41 | 1.35 | 1.29 | 1.18 | 1.00 |

KOR5™ DT • 6 Spannuten• 3 x D • Anwendungsdaten • Metrisch

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||

| Side Milling (A) | KCSM15 | Recommended feed per tooth (fz = mm/th) for side milling (A). | |||||||||||

| A | Cutting Speed

|

D1

|

|||||||||||

| Material

|

ap | ae | min | max | mm | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 0 | 3 x D | 0.1 x D | 150 | – | 440 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 |

| 1 | 3 x D | 0.1 x D | 150 | – | 440 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 | |

| 2 | 3 x D | 0.1 x D | 140 | – | 418 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 | |

| 3 | 3 x D | 0.1 x D | 120 | – | 352 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 | |

| 4 | 3 x D | 0.1 x D | 90 | – | 330 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,106 | 0,117 | |

| 5 | 3 x D | 0.1 x D | 60 | – | 220 | fz | 0,048 | 0,058 | 0,067 | 0,084 | 0,097 | 0,109 | |

| 6 | 3 x D | 0.1 x D | 50 | – | 165 | fz | 0,040 | 0,048 | 0,056 | 0,068 | 0,078 | 0,085 | |

| M | 1 | 3 x D | 0.1 x D | 90 | – | 253 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 |

| 2 | 3 x D | 0.1 x D | 60 | – | 176 | fz | 0,048 | 0,058 | 0,067 | 0,084 | 0,097 | 0,109 | |

| 3 | 3 x D | 0.1 x D | 60 | – | 154 | fz | 0,040 | 0,048 | 0,056 | 0,068 | 0,078 | 0,085 | |

| K | 1 | 3 x D | 0.1 x D | 120 | – | 330 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 |

| 2 | 3 x D | 0.1 x D | 110 | – | 308 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 | |

| 3 | 3 x D | 0.1 x D | 110 | – | 286 | fz | 0,048 | 0,058 | 0,067 | 0,084 | 0,097 | 0,109 | |

| S | 1 | 3 x D | 0.1 x D | 50 | – | 198 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 |

| 2 | 3 x D | 0.1 x D | 25 | – | 88 | fz | 0,032 | 0,038 | 0,045 | 0,056 | 0,065 | 0,074 | |

| 3 | 3 x D | 0.1 x D | 25 | – | 88 | fz | 0,032 | 0,038 | 0,045 | 0,056 | 0,065 | 0,074 | |

| 4 | 3 x D | 0.1 x D | 50 | – | 132 | fz | 0,044 | 0,053 | 0,062 | 0,077 | 0,089 | 0,100 | |

| H | 1 | 3 x D | 0.1 x D | 80 | – | 308 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,106 | 0,117 |

| 2 | 3 x D | 0.1 x D | 70 | – | 264 | fz | 0,040 | 0,048 | 0,056 | 0,068 | 0,078 | 0,085 | |

-

KOR™6DT

-

KOR™ Series End Mills: Solid End Mills for Dynamic Milling