Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Beginnen Sie das Jahr 2024 mit phänomenalen Einsparungen bei Bohrwerkzeugen.

Jetzt bestellen.

Kennametal steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

- Metallbearbeitungswerkzeuge

- /

- Bohren

- /

- Modulare Bohrer

- /

- Modulares Bohrsystem KSEM PLUS™

- /

- KSEM PLUS™ Schneidkörper

- /

- KSEM PLUS™ Center Inserts

- /

- KSEM PLUS™ • Zentrumsschneide • HPG-Geometrie

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

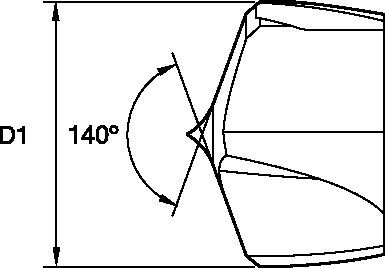

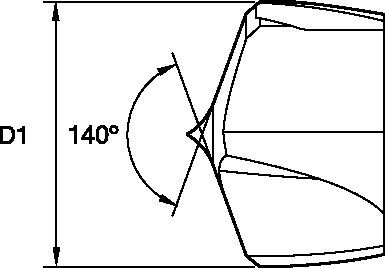

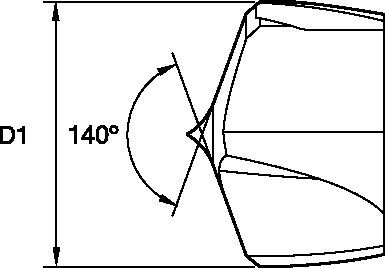

KSEM PLUS™ • Zentrumsschneide • HPG-Geometrie

Modulares Bohren • Hartmetall-Schneidkörper für KSEM PLUS™ A1- und B1-Bohrköpfe

Features and benefits

- HPG-Geometrie für modulares Bohren in Stählen, rostfreiem Stahl, Gusseisen und Hochtemperaturlegierungen.

- Mit gerader Schneide für maximale Stabilität bei kurzspanenden Stählen und unterbrochenen Schnitten.

Uses and application

Bohren

| D1 | tolerance h8 + / - |

| .500–.709 | +.000/-.0010 |

|

|

+.000/-.0013 |

|

|

+.000/-.0015 |

| D1 | tolerance h8 + / - |

| 12,5–18 | +0,000/-0,027 |

|

|

+0,000/-0,033 |

|

|

+0,000/-0,039 |

| Metric | |||||||||||

| Material

|

Condition | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||||||

| Range

|

|||||||||||

| Min | Starting Value | Max | Ø | KSEM 14….17 DFR/DFC04... 28.00

|

KSEM 15….18 DFT/DFC05… 31,74

|

KSEM 13….22 DFT/DFC06... 36,00

|

KSEM 18….28 DFT/DFC07... 45,00

|

KSEM 20….34 DFT/DFC09... 56,00

|

|||

| P | 1 | S | 115 | 235 | 290 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 90 | 160 | 215 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 65 | 100 | 140 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 90 | 190 | 230 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | |

| U | 71 | 130 | 170 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 3 | S | 90 | 180 | 230 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 120 | 170 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 106 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 4 | S | 90 | 140 | 220 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 110 | 160 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 5 | S | 90 | 130 | 210 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 100 | 150 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 100 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 6 | S | 70 | 90 | 180 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 50 | 75 | 120 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 40 | 60 | 100 | mm/r | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| M | 1 | S | 60 | 110 | 135 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 40 | 70 | 90 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 60 | 100 | 135 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 50 | 90 | 135 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 25 | 40 | 65 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| K | 1 | S | 90 | 170 | 230 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 |

| U | 60 | 120 | 160 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 40 | 70 | 90 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| 2 | S | 90 | 160 | 220 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | |

| U | 60 | 110 | 160 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 40 | 70 | 100 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| 3 | S | 90 | 150 | 210 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | |

| U | 60 | 100 | 150 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 35 | 60 | 90 | mm/r | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| N | 1 | S | 150 | 240 | 360 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 |

| U | 100 | 160 | 240 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 2 | S | 150 | 220 | 360 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 150 | 240 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 3 | S | 150 | 200 | 360 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 4 | S | 150 | 200 | 360 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 5 | S | 150 | 200 | 360 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 6 | S | 150 | 200 | 360 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 7 | S | 110 | 220 | 260 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 70 | 140 | 170 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 45 | 90 | 110 | mm/r | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| S | 1 | S | 25 | 50 | 75 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 20 | 40 | 60 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 15 | 30 | 50 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 20 | 40 | 60 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 35 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 20 | 40 | 60 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 4 | S | 20 | 40 | 60 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/r | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| Inch | |||||||||||

| Material

|

Condition | Cutting Speed

|

Recommended Feed Rate (fz) by Diameter | ||||||||

| Range

|

|||||||||||

| Min | Starting Value | Max | Ø | KSEM 14….17 DFR/DFC04... 1.102

|

KSEM 15….18 DFT/DFC05… 1.250

|

KSEM 13….22 DFT/DFC06... 1.417

|

KSEM 18….28 DFT/DFC07... 1.772

|

KSEM 20….34 DFT/DFC09... 2.205

|

|||

| P | 1 | S | 370 | 775 | 944 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 |

| U | 290 | 532 | 698 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 205 | 327 | 451 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 2 | S | 295 | 623 | 755 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 233 | 427 | 558 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 164 | 262 | 361 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 3 | S | 295 | 591 | 755 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 230 | 394 | 558 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 164 | 230 | 361 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 4 | S | 295 | 459 | 722 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 230 | 361 | 525 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 264 | 262 | 361 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 5 | S | 295 | 427 | 689 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 230 | 328 | 689 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 164 | 230 | 492 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 6 | S | 230 | 295 | 591 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 164 | 246 | 394 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 131 | 197 | 328 | IPR | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| M | 1 | S | 197 | 361 | 443 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 |

| U | 131 | 230 | 295 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 98 | 164 | 213 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 2 | S | 197 | 328 | 443 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 131 | 197 | 295 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 98 | 164 | 213 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 3 | S | 164 | 295 | 443 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 131 | 197 | 295 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 82 | 131 | 213 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| K | 1 | S | 295 | 558 | 755 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 |

| U | 197 | 394 | 525 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| I | 131 | 230 | 295 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| 2 | S | 295 | 525 | 722 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | |

| U | 197 | 361 | 525 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| I | 131 | 230 | 328 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| 3 | S | 295 | 492 | 689 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | |

| U | 197 | 328 | 492 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| I | 115 | 197 | 295 | IPR | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| N | 1 | S | 492 | 787 | 1181 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 |

| U | 328 | 525 | 787 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 2 | S | 492 | 722 | 1181 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 3 | S | 492 | 722 | 1181 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 4 | S | 492 | 722 | 1181 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 5 | S | 492 | 722 | 1181 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 6 | S | 492 | 656 | 1181 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 459 | 787 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 295 | 525 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 7 | S | 361 | 722 | 853 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 230 | 459 | 558 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 148 | 295 | 361 | IPR | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| S | 1 | S | 82 | 164 | 246 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 |

| U | 66 | 131 | 197 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 49 | 98 | 164 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 2 | S | 66 | 131 | 197 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 49 | 98 | 148 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 39 | 82 | 115 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 3 | S | 66 | 131 | 197 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 49 | 98 | 148 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 39 | 82 | 131 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 4 | S | 66 | 131 | 197 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 49 | 98 | 148 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 39 | 82 | 131 | IPR | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| Metric | |||||||||||

| Condition | Cutting Speed

|

||||||||||

| Range

|

Recommended Feed Rate (fz) by Diameter | ||||||||||

| Material

|

Min | Starting Value | Max | Ø | KSEM 14….17 DFR/DFC04... 28,00

|

KSEM 15….18 DFT/DFC05… 31,75

|

KSEM 13….22 DFT/DFC06... 36,00

|

KSEM 18….28 DFT/DFC07... 45,00

|

KSEM 20….34 DFT/DFC09... 56,00

|

||

| P | 1 | S | 115 | 235 | 290 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 90 | 160 | 215 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 65 | 100 | 140 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 90 | 190 | 230 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | |

| U | 71 | 130 | 170 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 3 | S | 90 | 180 | 230 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 120 | 170 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 106 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 4 | S | 90 | 140 | 220 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 110 | 160 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 5 | S | 90 | 130 | 210 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 100 | 150 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 100 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 6 | S | 70 | 90 | 180 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 50 | 75 | 120 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 40 | 60 | 100 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| M | 1 | S | 60 | 110 | 135 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 40 | 70 | 90 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 60 | 100 | 135 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 50 | 90 | 135 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 25 | 40 | 65 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| K | 1 | S | 90 | 170 | 230 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 |

| U | 60 | 120 | 160 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 40 | 70 | 90 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | ||

| 2 | S | 90 | 160 | 220 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | |

| U | 60 | 110 | 160 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | ||

| I | 40 | 70 | 100 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| 3 | S | 90 | 150 | 210 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | |

| U | 60 | 100 | 150 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 35 | 60 | 90 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | ||

| N | 1 | S | 150 | 240 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 |

| U | 100 | 160 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 2 | S | 150 | 220 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 150 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 3 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 4 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 5 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 6 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 7 | S | 110 | 220 | 260 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 70 | 140 | 170 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 45 | 90 | 110 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| S | 1 | S | 25 | 50 | 75 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 15 | 30 | 50 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 35 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 4 | S | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||