Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Beginnen Sie das Jahr 2024 mit phänomenalen Einsparungen bei Bohrwerkzeugen.

Jetzt bestellen.

Kennametal steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

- RCMX

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

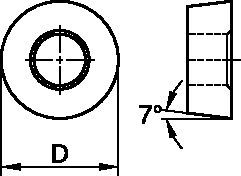

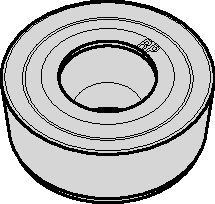

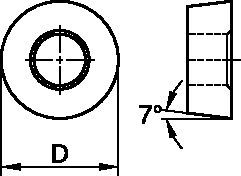

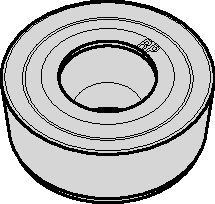

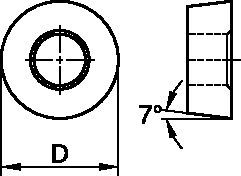

RCMX

Inserts

Features and benefits

Kennametal stocks a complete line of standard inserts for wheel and axle machining. Inserts are available in various styles, sizes, and grades.

Wheel boring — moulded chipbreaker inserts in round, square, octagon, and regrindable inserts.

Axle turning — triangle- and diamond-shaped inserts with chipbreakers.

Wheel turning — rectangular and square styles, with or without moulded chipbreakers.

Wheel turning — round buttons with centre hole for locking.