Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto Konto ändern

Lieferadresse Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

Notifications

Mark all as read- Passwort ändern

- Mein Profil

- Abmelden

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Mehr fräsern, weniger zahlen – mit unseren zeitlich begrenzten Angeboten. Jetzt bestellen.

Kennametal steht Ihnen zur Diensten

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname:{{SolutionName}}- Produkte

- /

- S2S Weldon Shank • Inch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

S2S Weldon Shank • Inch

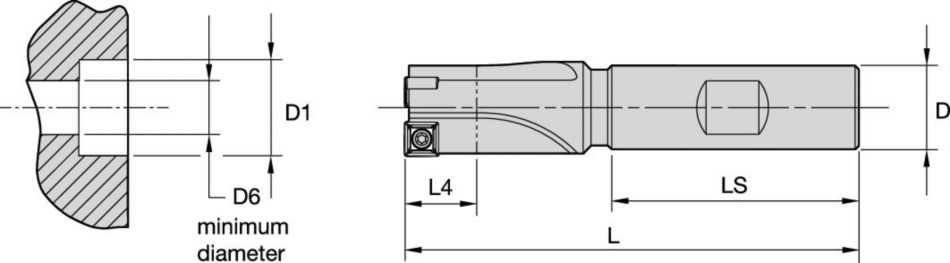

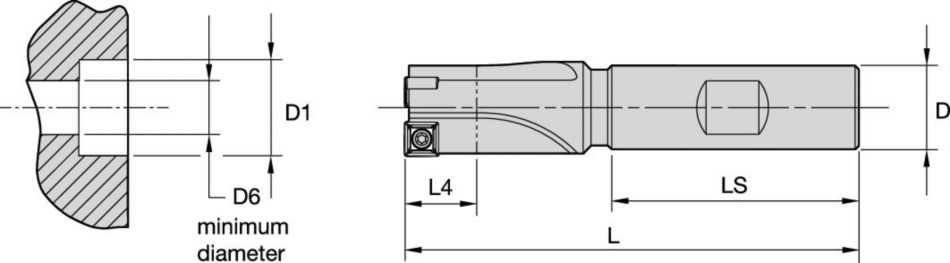

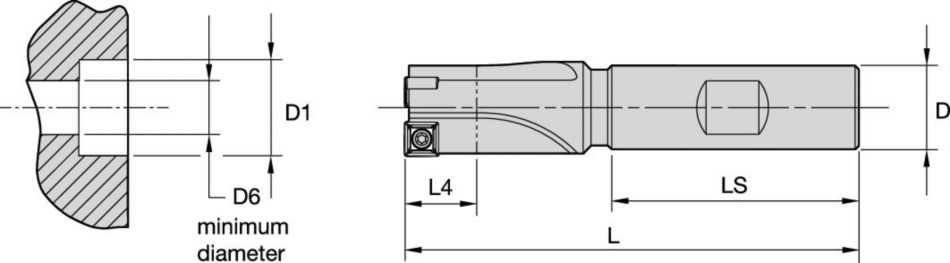

CTR — Senken

Features and benefits

- CTR Counterboring Tools are designed for high-production screw-head counterbores and similar counterboring operations.

- Extremely unequal insert positioning and flutes.

- S2 S inserts reduct additional drill operations to achieve a precise 90° bottom.

- Counterboring tool shipped with insert screws and Torx wrench.

Uses and application

Außenkühlung: Bohren

Zylinderschaft – Weldon

Senken

Schneidreihen: 2

Schneidreihen: 3

| Material | Cutting Speed | Metric | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | SPHX06... Ø 15-22 | SPHX07 Ø 18-26 | SPHX09 Ø 23-37 | SPHX12 Ø 24-47 | |||||||

| P | 1 | 100 | 140 | 180 | mm/r | 0,19 | 0,31 | 0,23 | 0,33 | 0,24 | 0,38 | 0,3 | 0,5 |

| 2 | 90 | 125 | 160 | mm/r | 0,19 | 0,31 | 0,23 | 0,33 | 0,24 | 0,38 | 0,3 | 0,5 | |

| 3 | 80 | 110 | 140 | mm/r | 0,17 | 0,28 | 0,21 | 0,30 | 0,22 | 0,35 | 0,27 | 0,45 | |

| 4 | 70 | 100 | 120 | mm/r | 0,16 | 0,26 | 0,19 | 0,28 | 0,20 | 0,32 | 0,25 | 0,42 | |

| 5 | 60 | 85 | 100 | mm/r | 0,15 | 0,24 | 0,18 | 0,25 | 0,18 | 0,29 | 0,23 | 0,38 | |

| 6 | 50 | 70 | 90 | mm/r | 0,15 | 0,24 | 0,18 | 0,25 | 0,18 | 0,29 | 0,23 | 0,38 | |

| M | 1 | 60 | 70 | 90 | mm/r | 0,11 | 0,21 | 0,14 | 0,24 | 0,16 | 0,26 | 0,18 | 0,33 |

| 2 | 50 | 60 | 80 | mm/r | 0,11 | 0,21 | 0,14 | 0,24 | 0,16 | 0,26 | 0,18 | 0,33 | |

| 3 | 40 | 50 | 70 | mm/r | 0,09 | 0,17 | 0,11 | 0,19 | 0,13 | 0,21 | 0,14 | 0,26 | |

| K | 1 | 100 | 160 | 240 | mm/r | 0,28 | 0,52 | 0,35 | 0,65 | 0,35 | 0,65 | 0,42 | 0,78 |

| 2 | 80 | 120 | 160 | mm/r | 0,25 | 0,47 | 0,32 | 0,59 | 0,32 | 0,59 | 0,38 | 0,71 | |

| 3 | 70 | 100 | 130 | mm/r | 0,23 | 0,43 | 0,29 | 0,54 | 0,29 | 0,54 | 0,35 | 0,65 | |

| N | 1 | 160 | 240 | 300 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 |

| 2 | 160 | 220 | 280 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 3 | 150 | 200 | 250 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 4 | 120 | 180 | 240 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 5 | 160 | 240 | 300 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 6 | 200 | 300 | 400 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| S | 1 | 30 | 40 | 60 | mm/r | 0,14 | 0,18 | 0,17 | 0,21 | 0,19 | 0,23 | 0,21 | 0,29 |

| 2 | 25 | 35 | 50 | mm/r | 0,13 | 0,16 | 0,15 | 0,19 | 0,17 | 0,21 | 0,19 | 0,26 | |

| 3 | 20 | 30 | 40 | mm/r | 0,11 | 0,14 | 0,13 | 0,16 | 0,15 | 0,18 | 0,16 | 0,22 | |

| 4 | 20 | 25 | 35 | mm/r | 0,09 | 0,12 | 0,11 | 0,14 | 0,13 | 0,15 | 0,14 | 0,19 | |

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | SPHX06... Ø 15-22 | SPHX07 Ø 18-26 | SPHX09 Ø 23-37 | SPHX12 Ø 24-47 | |||||||

| P | 1 | 328 | 459 | 590 | IPR | 0.007 | 0.012 | 0.009 | 0.013 | 0.009 | 0.015 | 0.012 | 0.020 |

| 2 | 295 | 410 | 525 | IPR | 0.007 | 0.012 | 0.009 | 0.013 | 0.009 | 0.015 | 0.012 | 0.020 | |

| 3 | 262 | 361 | 459 | IPR | 0.007 | 0.011 | 0.008 | 0.012 | 0.009 | 0.014 | 0.011 | 0.018 | |

| 4 | 230 | 328 | 393 | IPR | 0.006 | 0.010 | 0.008 | 0.011 | 0.008 | 0.012 | 0.010 | 0.016 | |

| 5 | 197 | 279 | 328 | IPR | 0.006 | 0.009 | 0.007 | 0.010 | 0.007 | 0.012 | 0.009 | 0.015 | |

| 6 | 164 | 230 | 295 | IPR | 0.006 | 0.009 | 0.007 | 0.010 | 0.007 | 0.012 | 0.009 | 0.015 | |

| M | 1 | 197 | 230 | 295 | IPR | 0.004 | 0.008 | 0.006 | 0.009 | 0.006 | 0.010 | 0.007 | 0.013 |

| 2 | 164 | 197 | 262 | IPR | 0.004 | 0.008 | 0.006 | 0.009 | 0.006 | 0.010 | 0.007 | 0.013 | |

| 3 | 131 | 164 | 230 | IPR | 0.003 | 0.007 | 0.004 | 0.008 | 0.005 | 0.008 | 0.006 | 0.010 | |

| K | 1 | 328 | 525 | 787 | IPR | 0.011 | 0.020 | 0.014 | 0.026 | 0.014 | 0.026 | 0.017 | 0.031 |

| 2 | 262 | 393 | 525 | IPR | 0.010 | 0.019 | 0.013 | 0.023 | 0.013 | 0.023 | 0.015 | 0.028 | |

| 3 | 230 | 328 | 426 | IPR | 0.009 | 0.017 | 0.011 | 0.021 | 0.011 | 0.021 | 0.014 | 0.026 | |

| N | 1 | 525 | 787 | 984 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 |

| 2 | 525 | 721 | 918 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 3 | 492 | 656 | 820 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 4 | 393 | 590 | 787 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 5 | 525 | 787 | 984 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 6 | 656 | 984 | 1311 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| S | 1 | 98 | 131 | 197 | IPR | 0.006 | 0.007 | 0.007 | 0.008 | 0.007 | 0.009 | 0.008 | 0.011 |

| 2 | 82 | 115 | 164 | IPR | 0.005 | 0.006 | 0.006 | 0.008 | 0.007 | 0.008 | 0.008 | 0.010 | |

| 3 | 66 | 98 | 131 | IPR | 0.004 | 0.005 | 0.005 | 0.006 | 0.006 | 0.007 | 0.006 | 0.009 | |

| 4 | 66 | 82 | 115 | IPR | 0.004 | 0.005 | 0.004 | 0.006 | 0.005 | 0.006 | 0.006 | 0.008 | |