Product Similar To :

Fix-Perfect™ • Shell Mill • Fine Pitch • Metric

Face Mill • Cast Iron Machining

Material Number1886331

ISO Catalog ID200C24RP00MD10CFANSI Catalog ID200C24RP00MD10CF

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- .caption

Face Milling

Milling - Through Coolant

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

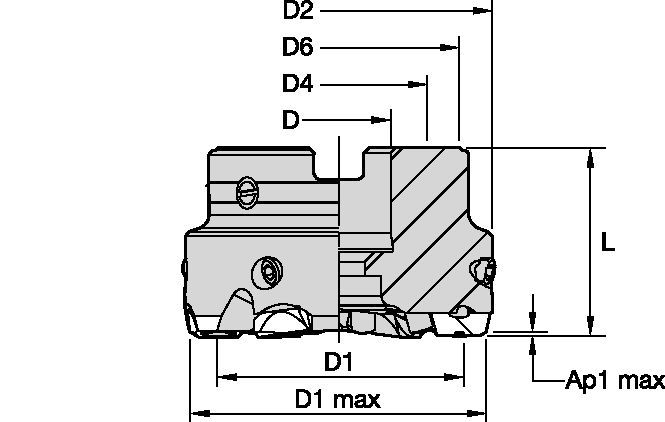

| Material Number | 1886331 |

| ISO Catalog ID | 200C24RP00MD10CF |

| ANSI Catalog ID | 200C24RP00MD10CF |

| [D1] Effective Cutting Diameter | 188.5 mm |

| [D1MAX] Maximum Cutting Diameter | 200 mm |

| [D] Adapter / Shank / Bore Diameter | 60 mm |

| [D4] Bolt Circle 4 | 101.6 mm |

| [D6] Hub Diameter | 180 mm |

| [L] Overall Length | 63 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1 mm |

| Number of Inserts | 24 |

| Weight Kilograms | 9,85 |

| Max RPM | 6350 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- .caption

Uses and application

Face Milling

Milling - Through Coolant

Milling - Side and Face

Features and benefits

- Milling cutters for fine-finishing applications in cast iron and compacted graphite iron (CGI).

- Perfect axial runout without insert adjustment.

- High-precision pocket seat for excellent floor finish and flatness.

- Easy handling and low-cost cutter set up.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..GD4W | 0,23 | 0,84 | 1,41 | 0,17 | 0,60 | 1,01 | 0,13 | 0,45 | 0,75 | 0,11 | 0,39 | 0,66 | 0,10 | 0,36 | 0,60 | .F..GD4W |

| .E..GD4W | 0,26 | 0,93 | 1,67 | 0,19 | 0,67 | 1,19 | 0,14 | 0,50 | 0,88 | 0,12 | 0,44 | 0,77 | 0,11 | 0,40 | 0,70 | .E..GD4W |

| .E..GD | 0,26 | 1,03 | 1,90 | 0,19 | 0,74 | 1,35 | 0,14 | 0,55 | 1,00 | 0,12 | 0,48 | 0,87 | 0,11 | 0,44 | 0,80 | .E..GD |

| Light | General | Heavy |

Recommended Starting Feeds [I.P.T.]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..GD4W | .004 | .005 | .007 | .003 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | .F..GD4W |

| .E..GD4W | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD4W |

| .E..GD | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 155 | 145 | 135 | 325 | 295 | 260 | 275 | 235 | 195 |

| 2 | 135 | 130 | 120 | 255 | 225 | 215 | 220 | 180 | 160 | |

| 3 | 120 | 105 | 95 | 215 | 190 | 170 | 185 | 150 | 130 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 910 | 770 | 640 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 720 | 590 | 520 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 600 | 500 | 420 | |

| N | 1–2 | 1980 | 1860 | 1770 | – | – | – | – | – | – |

| 3 | 1620 | 1440 | 1260 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | – | (Strong geometry) | ||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| K3 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use