Cartridges

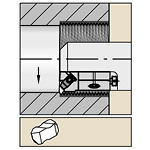

Top Notch™ threading cartridges are versatile and high-quality tools ideal for multiple applications. One of their key features is the secure mounting and clamping system, which ensures that your tools are held firmly in place during operations. This not only enhances the precision of your work but also contributes to the safety and efficiency of your machining processes. Cartridges are completely interchangeable in any boring bar, head, or tooling block manufactured to ANSI or ISO standards.

- P Steel (2)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(2)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(2)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(2)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(2)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(2)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(2)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(2)

- M Stainless Steel (2)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(2)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(2)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(2)

- K Cast Iron (2)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(2)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(2)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(2)

- N Non-Ferrous Materials (2)

- N1Wrought Aluminum (2)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(2)

- N4Copper, Brass, Zinc-based on machinability index range of 70-100 (2)

- N5Nylon, Plastics, Rubbers, Phenolics, Resins, Fiberglass (2)

- N6Carbon, Graphite Composites, CFRP (2)

- S High-Temp Alloys (2)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(2)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(2)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(2)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(2)

- H Hardened Materials (2)

- H1Hardened Materials 44-48 HRC(2)

Face Grooving (2)

Grooving (2)

Threading (2)

- 60 (2)

- BUTTRESS (2)

- UN (2)

- Heavily Interrupted Cut (2)

- Lightly Interrupted Cut (2)

- Smooth Cut (2)

- 55.0 mm(1)

- 55.67 mm(1)

- 0.075 mm(2)

- 0.1 mm(2)

- 0.175 mm(1)

- 0.2 mm(2)

- 0.25 mm(1)

- 0.35 mm(1)

- 0.5 mm(2)

- 0.75 mm(1)

- 0.775 mm(2)

- 1.0 mm(2)

- 1.2 mm(2)

- 1.25 mm(1)

- 1.5 mm(2)

- 1.6 mm(2)

- 1.75 mm(1)

- K313 (2)

- K420 (2)

- K68 (2)

- KC5010 (2)

- KC5025 (2)

- KC5410 (2)

- KC720 (2)

- KC730 (2)

- KC850 (2)

- KCK20 (1)

- KCK20B (2)

- KCP10B (2)

- KCP25B (2)

- KCP25C (2)

- KCU10 (2)

- KCU10B (2)

- KCU25 (2)

- KCU25B (2)

- KT315 (1)

- 0.5 mm(2)

- 0.787 mm(2)

- 0.8 mm(2)

- 0.889 mm(1)

- 0.991 mm(2)

- 1.0 mm(2)

- 1.041 mm(2)

- 1.19 mm(2)

- 1.194 mm(2)

- 1.2 mm(2)

- 1.39 mm(2)

- 1.397 mm(1)

- 1.4 mm(2)

- 1.473 mm(2)

- 1.5 mm(2)

- 1.57 mm(1)

- 1.575 mm(2)

- 1.69 mm(1)

- 1.7 mm(2)

- 1.702 mm(2)

- 1.75 mm(2)

- 1.94 mm(1)

- 1.95 mm(2)

- 1.956 mm(1)

- 2.0 mm(2)

- 2.007 mm(2)

- 2.2 mm(2)

- 2.235 mm(1)

- 2.24 mm(2)

- 2.25 mm(2)

- 2.388 mm(2)

- 2.5 mm(2)

- 2.74 mm(1)

- 2.743 mm(1)

- 2.75 mm(2)

- 2.997 mm(1)

- 3.0 mm(2)

- 3.175 mm(2)

- 3.18 mm(1)

- 3.2 mm(1)

- 3.245 mm(2)

- 3.27 mm(1)

- 3.5 mm(1)

- 3.81 mm(1)

- 3.82 mm(1)

- 3.835 mm(1)

- 3.84 mm(2)

- H T (1)

- H W (2)