Product Similar To:

KenCut™ AL • AADF • Square End • 2 Flutes • Plain Shank • Inch

Solid Carbide End Mill for Roughing and Finishing of Aluminum

Material Number5063236

ISO Catalog IDAADF156J2AANSI Catalog IDAADF156J2A

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 2

Helix Angle: 45°

Corner Style: Corner Radius

Corner Style: Square End

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5063236 |

| ISO Catalog ID | AADF156J2A |

| ANSI Catalog ID | AADF156J2A |

| Grade | KC625M |

| Adapter Style Machine Side | Straight-Cylindrical |

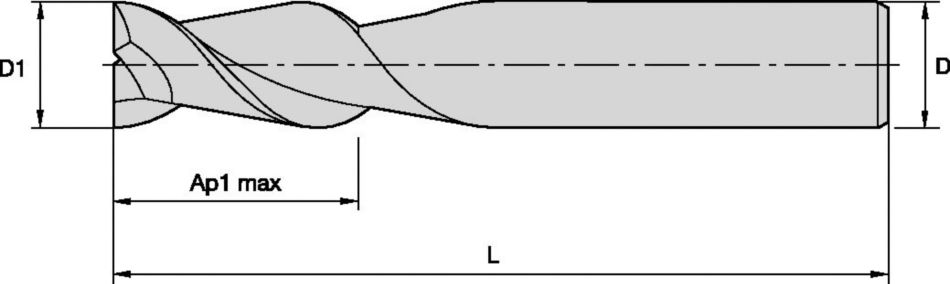

| [D1] Effective Cutting Diameter | 3.969 mm |

| [D1] Effective Cutting Diameter | 0.1563 in |

| [D] Adapter / Shank / Bore Diameter | 4.763 mm |

| [D] Adapter / Shank / Bore Diameter | 0.1875 in |

| [AP1MAX] 1st Maximum Cutting Depth | 14.288 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.5625 in |

| [L3] Usable Length | 14.288 mm |

| [L3] Usable Length | 0.5625 in |

| [L] Overall Length | 50.8 mm |

| [L] Overall Length | 2 in |

| [Z] Number of Flutes | 2 |

Uses and application

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 2

Helix Angle: 45°

Corner Style: Corner Radius

Corner Style: Square End

Grades

KC625M

Coated carbide grade with PVD (TiCN) coating. For universal use due to its high wear resistance and hardness. Only use wet or with MQL (minimum quantity lubrication).

Features and benefits

- Centre cutting for plunging and ramping operations.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| End Mill Tolerances | |||

| D1 | tolerance h6 + / - | D | tolerance h6 + / - |

| 1/8" | +0/-.002" | 1/8" | +0/-.00024" |

| 1/8 | +0/-.002" | 1/8 | +0/-.00031" |

| 1/4 | +0/-.00035" | 1/4 | +0/-.00035" |

| 13/32 | +0/-.00043" | 13/32 | +0/-.00043" |

| 23/32 | +0/-.00051" | 23/32 | +0/-.00051" |

Speeds & Feeds

| Material |  |  |  | |||||||||||||

| Side Milling (A) and Slotting (B) | K600 | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||

| A | B | Cutting Speed | D1 | |||||||||||||

| frac. | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | ap | min | max | dec. | 0.125 | 0.188 | 0.250 | 0.313 | 0.375 | 0.500 | 0.625 | 0.750 | 1.000 | ||

| N | 1 | 1.5 x D | 0.5 x D | 1.0 x D | 1640 | 6560 | IPT | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 |

| 2 | 1.5 x D | 0.5 x D | 1.0 x D | 1640 | 4920 | IPT | .0009 | .0014 | .0018 | .0023 | .0027 | .0036 | .0045 | .0054 | .0072 | |

| 3 | 1.5 x D | 0.5 x D | 1.0 x D | 1640 | 4920 | IPT | .0008 | .0012 | .0016 | .0020 | .0024 | .0032 | .0039 | .0047 | .0063 | |

| 4 | 1.5 x D | 0.5 x D | 1.0 x D | 1310 | 2460 | IPT | .0008 | .0012 | .0016 | .0020 | .0024 | .0032 | .0039 | .0047 | .0063 | |

| 5 | 1.5 x D | 0.5 x D | 1.0 x D | 820 | 3280 | IPT | .0010 | .0015 | .0020 | .0025 | .0030 | .0041 | .0051 | .0061 | .0081 | |

I have read and accepted the Terms & Conditions of use