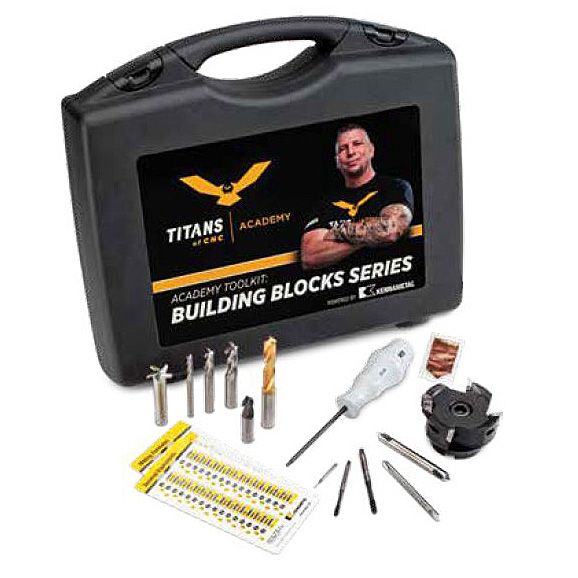

Metalworking Tools

Kennametal metalworking tools and tooling systems are the easiest and most convenient way to get your job done right. Our high-performance First Choice milling and drilling tools are versatile, working effectively on most of your machining applications. If the realities of your business require custom metalworking tools, we also create state-of-the-art solutions to help your company meet its current and future needs.