Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

Kennametal a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Comience el 2024 con un ahorro fenomenal en herramientas de taladrado.

Compre ahora

Kennametal a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Productos

- /

- Drill Fix™ DFT™ • HD Inserts

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

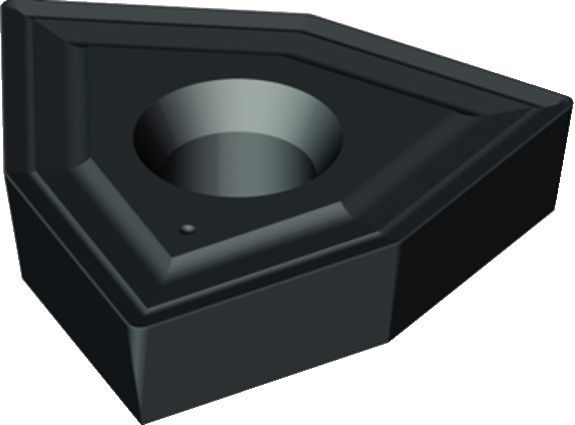

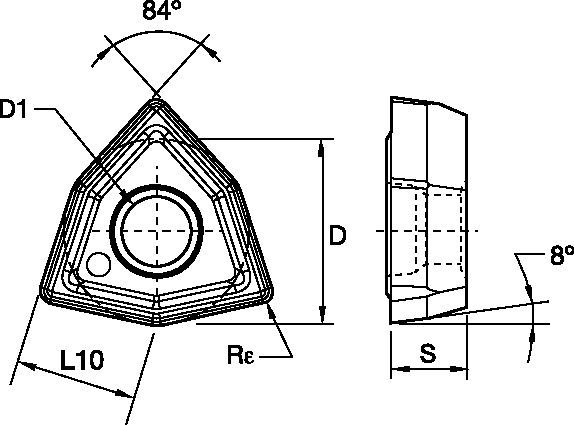

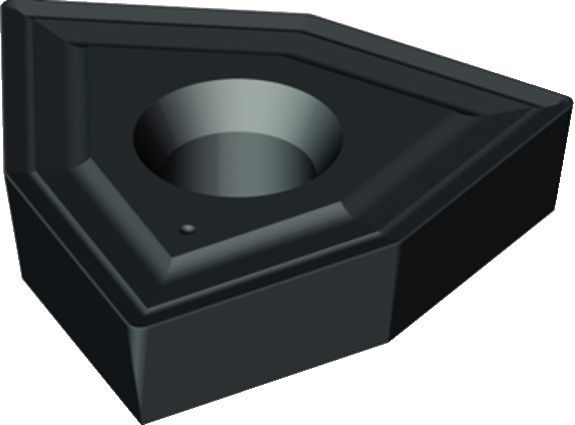

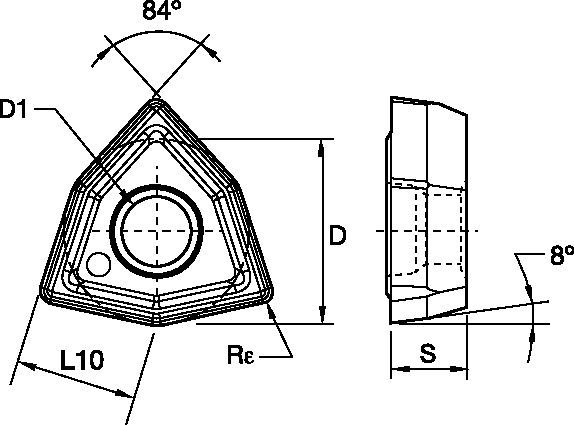

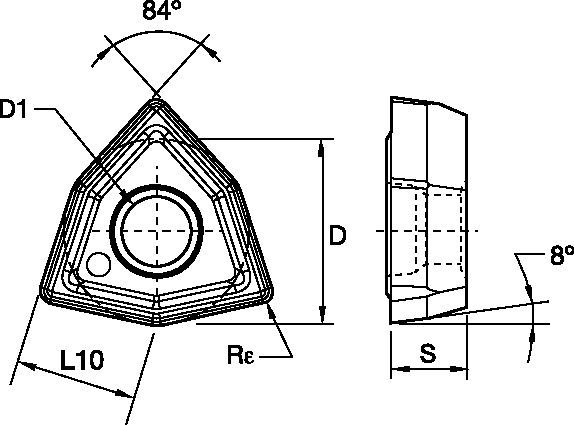

Drill Fix™ DFT™ • HD Inserts

Drill Fix™ DFT™ • HD Inserts

Features and benefits

- Insert geometry for large inserts.

- General purpose chipbreaker geometry.

ADVERTENCIA • Drill Fix DFR

| WARNING During through-hole operations, a slug or disc is produced as the tool breaks through the workpiece. When the drill is stationary and the workpiece is rotating, this slug may be hurled from the chuck by centrifugal force. Provide adequate shielding to protect bystanders. |

| D | LS | CS |

| 32 | 58 | R 1/4 BSP |

| 40 | 68 | R 1/4 BSP |

| 50 | 68 | R 1/4 BSP |

| Metric | |||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (f) by Diameter | |||||||||

| Range

|

|||||||||||||||

| Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | ||||||

| P | 1 | S | O | MD | KCU25 | 310 | 325 | 360 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU25 | 200 | 215 | 230 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KCU40 | 130 | 135 | 150 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | HP | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU25 | 200 | 215 | 230 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU25 | 180 | 195 | 220 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | HP | KC7140 | |||||||||||||

| 4 | S | O | HP | KCU25 | 220 | 250 | 300 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 150 | 180 | 220 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 90 | 110 | 140 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | ||

| I | HP | KC7140 | |||||||||||||

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | ||

| I | HP | KC7140 | |||||||||||||

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | ||

| I | HP | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed

|

|||||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | |

| P | 1 | S | O | MD | KCU25 | 310 | 325 | 360 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 |

| 1 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 1 | U | O | MD | KCU25 | 200 | 215 | 230 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 1 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 1 | I | O | MD | KCU40 | 130 | 135 | 150 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 1 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 2 | S | O | HP | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 2 | S | I | HP | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 2 | U | O | HP | KCU25 | 200 | 215 | 230 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 2 | U | I | HP | KC7140 | 200 | 215 | 230 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 2 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 2 | I | I | HP | KC7140 | 130 | 135 | 150 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 3 | S | O | HP | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 3 | S | I | HP | KC7140 | 260 | 285 | 320 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 3 | U | O | HP | KCU25 | 180 | 195 | 220 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 3 | U | I | HP | KC7140 | 180 | 195 | 220 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 3 | I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 3 | I | I | HP | KC7140 | 110 | 120 | 140 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 4 | S | O | HP | KCU25 | 220 | 250 | 300 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 4 | S | I | HP | KC7140 | 220 | 250 | 300 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 4 | U | O | HP | KCU40 | 150 | 180 | 220 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 4 | U | I | HP | KC7140 | 150 | 180 | 220 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 4 | I | O | HP | KC7140 | 90 | 110 | 140 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 4 | I | I | HP | KC7140 | 90 | 110 | 140 | mm/r | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,15–0,25 | 0,19–0,31 | 0,19–0,31 | |

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 5 | S | I | HP | KC7140 | 180 | 200 | 220 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 5 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 5 | U | I | HP | KC7140 | 120 | 135 | 150 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 5 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 5 | I | I | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 6 | S | I | HP | KC7140 | 180 | 200 | 220 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 6 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 6 | U | I | HP | KC7140 | 120 | 135 | 150 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 6 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| 6 | I | I | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,05–0,10 | 0,07–0,13 | 0,09–0,15 | 0,11–0,18 | 0,12–0,23 | 0,12–0,23 | |

| Metric | |||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (f) by Diameter | |||||||||

| Range

|

|||||||||||||||

| Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | ||||||

| M | 1 | S | O | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KC7140 | 80 | 110 | 140 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | ||

| I | MD | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed

|

|||||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | |

| M | 1 | S | O | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 |

| 1 | S | I | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 1 | U | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 1 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 1 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 1 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 2 | S | O | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 2 | S | I | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 2 | U | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 2 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 2 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 2 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 3 | S | O | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 3 | S | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 3 | U | O | MD | KC7140 | 80 | 110 | 140 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 3 | U | I | MD | KC7140 | 80 | 110 | 140 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 3 | I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| 3 | I | I | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | 0,11–0,21 | 0,11–0,21 | |

| Metric | |||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (f) by Diameter | |||||||||

| Range

|

|||||||||||||||

| Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | ||||||

| K | 1 | S | O | HP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 120 | 155 | 200 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KCU40 | 80 | 100 | 125 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | ||

| I | HP | KC7140 | |||||||||||||

| 2 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 80 | 100 | 120 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 80 | 100 | 120 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | ||

| I | HP | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed

|

|||||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | |

| K | 1 | S | O | HP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 |

| 1 | S | I | HP | KCU40 | 200 | 240 | 300 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 1 | U | O | HP | KCU25 | 120 | 155 | 200 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 1 | U | I | HP | KCU40 | 120 | 155 | 200 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 1 | I | O | HP | KCU40 | 80 | 100 | 125 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 1 | I | I | HP | KC7140 | 80 | 100 | 125 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 2 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 2 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 2 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 2 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 2 | I | O | HP | KCU40 | 80 | 100 | 120 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 2 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 3 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 3 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 3 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 3 | I | O | HP | KCU40 | 80 | 100 | 120 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| 3 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,07–0,13 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,21–0,39 | 0,21–0,39 | |

| Metric | |||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (f) by Diameter | |||||||||

| Range

|

|||||||||||||||

| Min | Starting Value | Max | Ø | DFT03 16

|

DFT05 25

|

DFT06 32

|

DFT07 41

|

DFT09... 49

|

DFT11 69

|

||||||

| N | 1 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 |

| I | ST | KD1425 | |||||||||||||

| U | O | HP | KCU40 | 300 | 400 | 500 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KMF | |||||||||||||

| 2 | S | O | ST | KD1425 | 375 | 550 | 775 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST | KD1425 | |||||||||||||

| U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KMF | 175 | 250 | 325 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KMF | |||||||||||||

| 3 | S | O | ST | KD1425 | 350 | 500 | 650 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST | KD1425 | |||||||||||||

| U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KMF | 150 | 250 | 350 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KMF | |||||||||||||

| 4 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST | KD1425 | |||||||||||||

| U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KMF | |||||||||||||

| 5 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST | KD1425 | |||||||||||||

| U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KMF | |||||||||||||

| 6 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST | KD1425 | |||||||||||||

| U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KCU40 | |||||||||||||

| I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | ||

| I | HP | KMF | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed

|

|||||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFT03 16

|

DFT05 25

|

DFT06 32

|

DFT07 41

|

DFT09... 49

|

DFT11 69

|

|

| N | 1 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 |

| 1 | S | I | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 1 | U | O | HP | KCU40 | 300 | 400 | 500 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 1 | U | I | HP | KCU40 | 300 | 400 | 500 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 1 | I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 1 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | S | O | ST | KD1425 | 375 | 550 | 775 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | S | I | ST | KD1425 | 375 | 550 | 775 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | U | I | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | I | O | HP | KMF | 175 | 250 | 325 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | I | I | HP | KMF | 175 | 250 | 325 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | S | O | ST | KD1425 | 350 | 500 | 650 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | S | I | ST | KD1425 | 350 | 500 | 650 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | U | I | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | I | O | HP | KMF | 150 | 250 | 350 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | I | I | HP | KMF | 150 | 250 | 350 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | S | I | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | U | I | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | S | O | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | S | I | ST | KD1425 | 400 | 600 | 800 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | U | I | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | I | O | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| Metric | |||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Cutting Speed

|

Recommended Feed Rate (f) by Diameter | |||||||||

| Range

|

|||||||||||||||

| Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | ||||||

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,14 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | ||

| I | MD | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed

|

|||||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||||

| Material

|

Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFT03... 16,00–24,00 | DFT05... 25,00–32,00 | DFT06... 33,00–40,00 | DFT07... 41,00–48,00 | DFT09... 49,00–68,00 | DFT011... 69,00–82,00 | |

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,14 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 |

| 1 | S | I | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,14 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 1 | U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 1 | U | I | HP | KC7140 | 40 | 50 | 60 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 1 | I | O | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 1 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 2 | S | I | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 2 | U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 2 | U | I | HP | KC7140 | 30 | 40 | 50 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 2 | I | O | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 2 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,13 | 0,08–0,13 | |

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 3 | S | I | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 3 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 3 | U | I | HP | KC7140 | 50 | 60 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 3 | I | O | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 3 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 4 | S | I | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 4 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 4 | U | I | HP | KC7140 | 50 | 60 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 4 | I | O | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |

| 4 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,06–0,10 | 0,09–0,15 | 0,09–0,15 | |