Le damos la bienvenida

Confirme sus preferencias

Actualizar preferencias

Sugerencias de productos

Product Family suggestions

Kennametal a su servicio

Hola, User Name

Su cuenta seleccionada:

Hay un problema con su cuenta. Por favor, póngase en contacto con el servicio de atención al cliente.

Número de cliente

Cambiar cuenta

Dirección de envío (#)

Cambiar cuenta

- Panel de control

- Gestionar pedidos

- Gestionar canales

- Libreta de direcciones

-

Notifications

Mark all as read - Cambiar contraseña

- Mi perfil

- Cerrar sesión

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Kennametal a su servicio

Artículo(s)

añadido correctamente al carrito

Ver carrito

Ver carrito

Edición de la solución

Añadiendo solución

Nombre de la solución: {{SolutionName}}- Productos

- /

- Herramientas de trabajo de los metales

- /

- Fresado

- /

- Fresado con metal duro integral

- /

- Fresas de mango de metal duro integral de alto rendimiento

- /

- Fresas de mango de metal duro integral de alto rendimiento HARVI™ I TE

- /

- HARVI™ I TE • Biselado • 4 canales • Mango Weldon® • Sistema métrico

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

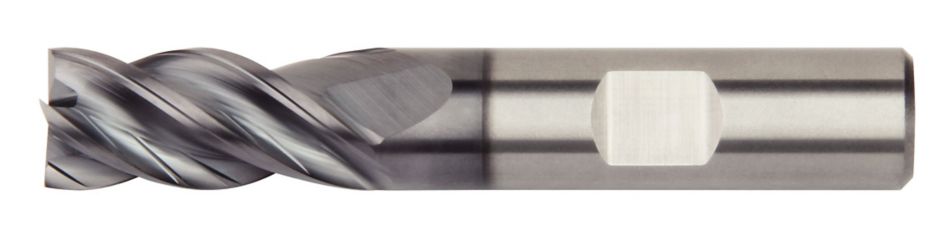

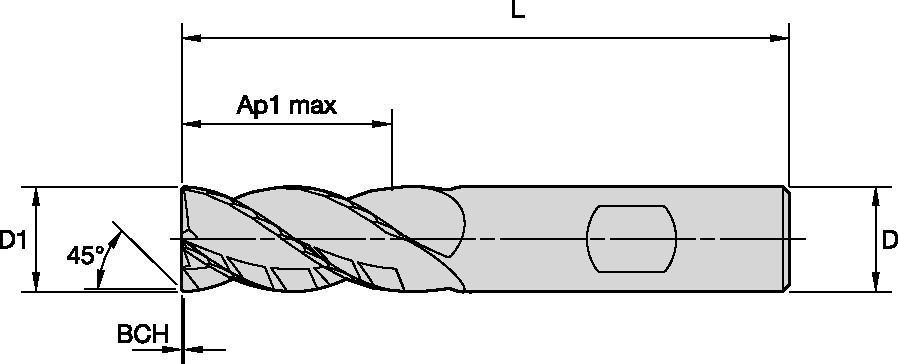

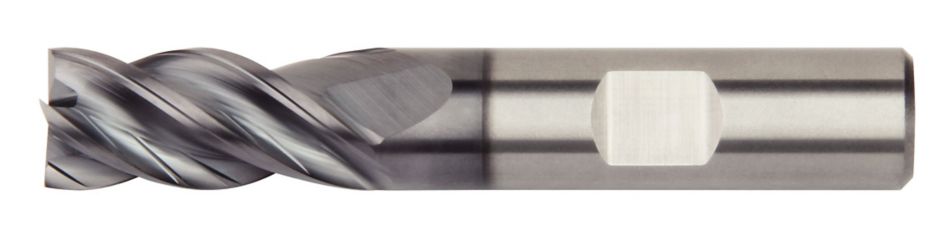

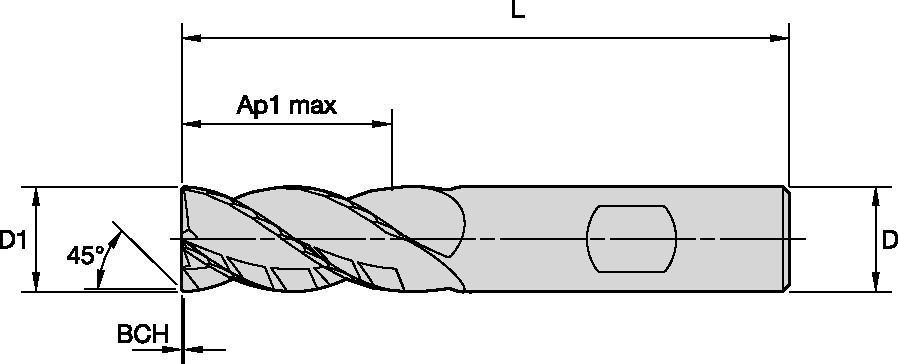

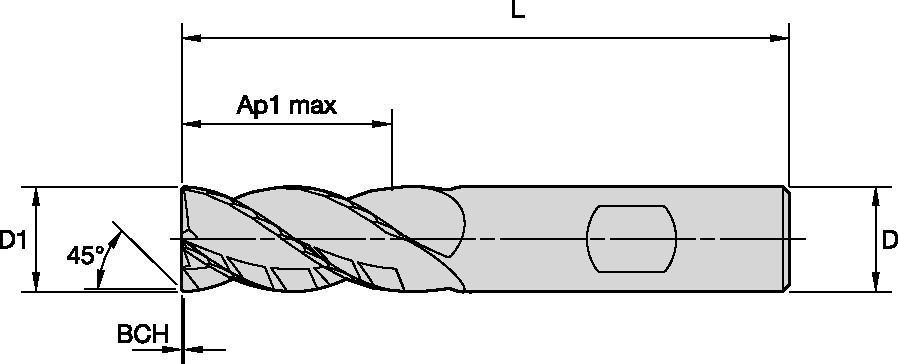

HARVI™ I TE • Biselado • 4 canales • Mango Weldon® • Sistema métrico

Fresa de mango de cuatro canales HARVI™ I TE para desbaste y acabado que cubre la más amplia gama de aplicaciones y materiales

Features and benefits

- Fresa de mango de metal duro integral para aceros, acero inoxidable, fundición y aleaciones de alta temperatura.

- Las fresas de mango de metal duro integral HARVI™ I TE cubren todo tipo de operaciones, incluido el fresado dinámico y operaciones de fresado descendente extremo.

- Las fresas de mango de metal duro integral HARVI™ I TE representan la máxima evacuación del metal, la máxima productividad y la máxima ventaja.

- Las fresas de mango de metal duro integral HARVI™ I TE cuentan con canales divididos asimétricos, hélice variable, extremo frontal torcido, alivio excéntrico de varias caras y cámaras de virutas dentro de los canales.

- Corte al centro para operaciones de vaciado y rectificado en rampa.

Uses and application

Corner Style: Corner Chamfer

Trochoidal Milling

100147465

Fresado helicoidal

Vaciado

Rectificado en rampa: Material en bruto

Ranurado: Placa cuadrada

Fresado lateral/Fresado en escuadra: Bisel simplificado

Dimensiones de la herramienta: Configuración del canal: 4

Mango — Weldon cilíndrico

Mecanizado de alojamientos

Fresado lateral/Fresado en escuadra: Desbaste

Adjustment Factor for Feed and Speed Calculation • Metric

| Ae/D | 2% | 4% | 5% | 8% | 10% | 12% | 20% | 30% | 40% | 50% | 100% | |

| Speed factor | Kv | 2,1

|

1,6

|

1,6

|

1,6 | 1,4 | 1,38 | 1,3 | 1,2 | 1,1 | 1 | 0,9 |

| Feed factor | KFz | 3,58 | 2,56 | 2,3 | 1,84 | 1,67 | 1,54 | 1,25 | 1,09 | 1,02 | 1 | 1 |

| Ae/D | 2% | 4% | 5% | 8% | 10% | 12% | 20% | 30% | 40% | 50% | 100% | |

| Speed factor | Kv | 2.1

|

1.6

|

1.6

|

1.6 | 1.4 | 1.38 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| Feed factor | KFz | 3.58 | 2.56 | 2.3 | 1.84 | 1.67 | 1.54 | 1.25 | 1.09 | 1.02 | 1 | 1 |

HARVI™ I TE • 4 canales • Datos de aplicación • Sistema métrico

| Ae/D | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | 20.00% | 30.00% | 40.00% | 50.00% | |

| Speed factor | Kv | 2 | 1.5 | 1.45 | 1.4 | 1.35 | 1.25 | 1.2 | 1 | 1 |

| Feed factor | KFz | 2.4 | 2.3 | 2.2 | 2 | 1.7 | 1.25 | 1.02 | 1 | 1 |

<="" td=""> <="" td=""> |  <="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||||||||||||

| Side Milling (A) and Slotting (B) | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||||||

| KCPM15/KCSM15 | D1

|

||||||||||||||||||||||

| A | B | Cutting Speed

|

|||||||||||||||||||||

| Material

|

ap | ae | ap | Min | Max | mm | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| P | 0 | 1,5 x D | 0,5 x D | 1,25 x D | 150 | – | 200 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 1 | 1,5 x D | 0,5 x D | 1,25 x D | 150 | – | 200 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 2 | 1,5 x D | 0,5 x D | 1,25 x D | 140 | – | 190 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 3 | 1,5 x D | 0,5 x D | 1,25 x D | 120 | – | 160 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 4 | 1,5 x D | 0,5 x D | 1,25 x D | 90 | – | 150 | fz | 0,008 | 0,010 | 0,012 | 0,021 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 | |

| 5 | 1,5 x D | 0,5 x D | 1,25 x D | 60 | – | 100 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 6 | 1,5 x D | 0,5 x D | 1,25 x D | 50 | – | 75 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| M | 1 | 1,5 x D | 0,5 x D | 1,25 x D | 90 | – | 115 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D | 0,5 x D | 1,25 x D | 60 | – | 80 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D | 0,5 x D | 1,00 x D | 60 | – | 70 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| K | 1 | 1,5 x D | 0,5 x D | 1,00 x D | 120 | – | 150 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 2 | 1,5 x D | 0,5 x D | 1,00 x D | 110 | – | 140 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 3 | 1,5 x D | 0,5 x D | 1,00 x D | 110 | – | 130 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| S | 1 | 1,5 x D | 0,3 x D | 0,75 x D | 50 | – | 90 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D | 0,3 x D | 0,75 x D | 50 | – | 80 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D | 0,5 x D | 0,50 x D | 25 | – | 40 | fz | 0,005 | 0,006 | 0,007 | 0,012 | 0,014 | 0,018 | 0,021 | 0,029 | 0,035 | 0,041 | 0,046 | 0,051 | 0,055 | 0,059 | 0,067 | |

| 4 | 1,5 x D | 0,5 x D | 1,25 x D | 50 | – | 60 | fz | 0,006 | 0,007 | 0,009 | 0,015 | 0,017 | 0,023 | 0,028 | 0,040 | 0,049 | 0,057 | 0,064 | 0,071 | 0,076 | 0,082 | 0,092 | |

| H | 1 | 1,5 x D | 0,5 x D | 1,00 x D | 80 | – | 140 | fz | 0,008 | 0,010 | 0,012 | 0,021 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 |

| 2 | 1,5 x D | 0,2 x D | 1,00 x D | 70 | – | 120 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |