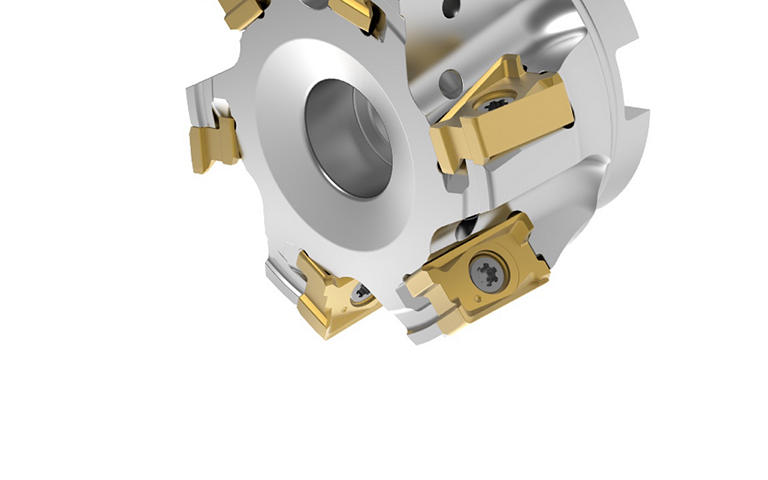

Mill 4-11™ - 90° shoulder milling to the extreme

The Mill 4-11 Series is specially engineered to achieve excellent surface quality and higher metal removal rates in shoulder milling applications. Its unique design allows you to apply the tool in multiple passes (step down) with outstanding results. From roughing to finishing operations, the Mill 4-11 series is applicable in a wide range of workpiece materials: steel, cast iron, stainless steel, non-ferrous materials, and high-temp alloys.

- Double-sided strong insert with 4 cutting edges.

- High positive geometry for lower cutting forces.

- Superior wall and surface finish capabilities.

- Comprehensive offering to cover all applications in all material groups.