Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client

Modifier le compte

Compte de livraison

Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

-

Notifications

Mark all as read - Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Kennametal à votre service

Support Clients

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution: {{SolutionName}}- Produits

- /

- B271Z_HP (15 x D) • KCMS20 • Queue Z • Forets hautes performances pour trous profonds

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

B271Z_HP (15 x D) • KCMS20 • Queue Z • Forets hautes performances pour trous profonds

Forets pour Trou Profond Beyond™ SD • Multiples Matériaux • Arrosage Interne

Features and benefits

- Forets pour trous profonds en carbure monobloc hautes performances avec arrosage central pour le perçage de l'acier, la fonte et les métaux non ferreux.

- Foret SC spécifique à l'application conçu pour le perçage jusqu'à 15 x D à une vitesse jusqu'à 4 fois plus importante que les forets conventionnels en acier rapide et à canon.

- La plus large gamme de diamètres du marché : 2,383–16mm (.0938–.6299″).

- La géométrie de pointe KMH est disponible en semi-standard, en particulier pour les applications sur vilebrequins

- Le KCPK20™ est une nuance (B27_HPG) AlCrN-TiAlN revêtue qui présente une résistance à l'usure exceptionnelle. Nouveau carbure à grain ultra fin assurant la fiabilité du processus à vitesses d'avance élevées dans l'acier et la fonte.

- La nuance non revêtue KN25™ Beyond (B27_HPS) à la surface polie assure une très bonne évacuation des copeaux et évite la formation d'arêtes rapportées dans l'aluminium et les alliages hautes températures, même avec un arrosage basse pression ou MQL.

Uses and application

Drilling: Stacked Plates

Perçage

Perçage : Sortie inclinée

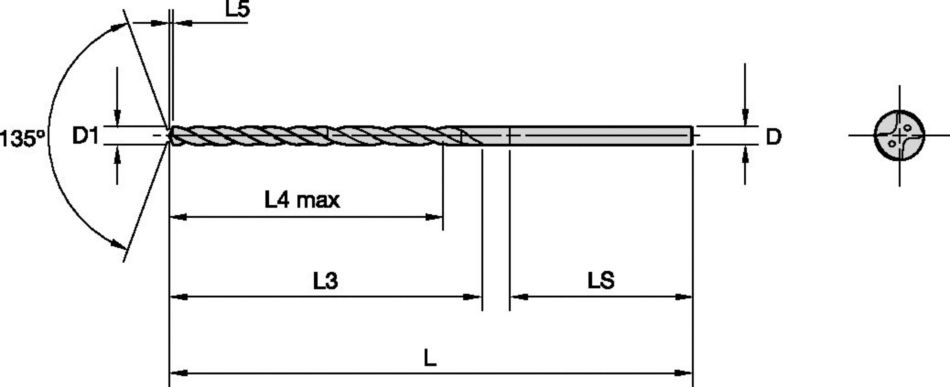

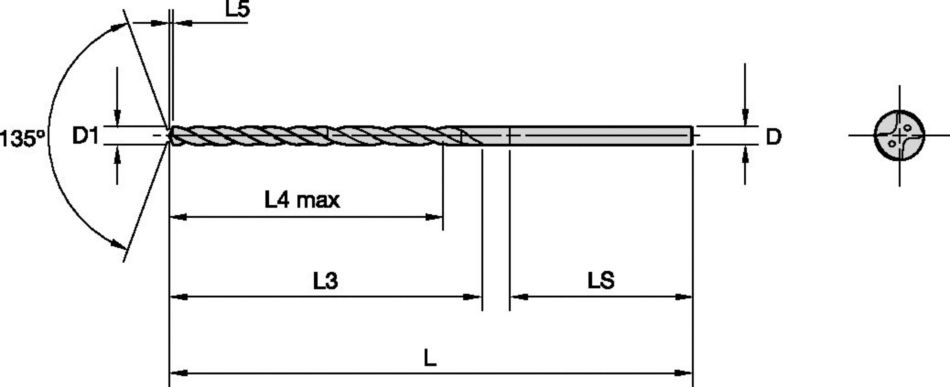

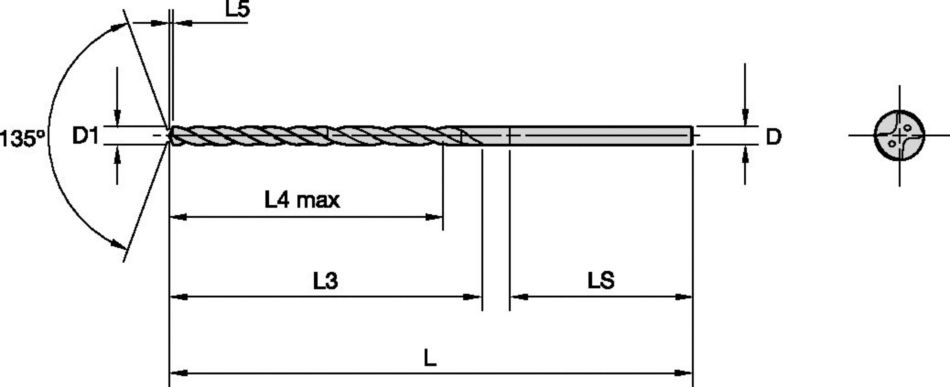

Dimensions de l'outil : 2 goujures/4 listels/lubrifiant

DIN 6535

Perçage — Arrosage interne

Arrosage interne : MQL (Quantité minimale de lubrification) : Perçage

Queue — Cylindrique Classique ≤h6

Angle d'hélice : 30°

Drilling: Cross-Hole Drilling

| Tolerance • Inch | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0394–.1181 | .0000/-.0004 | .0000/-.0006 |

|

|

.0002/.0006 | .0000/-.0003 |

|

|

.0002/.0008 | .0000/-.0004 |

|

|

.0003/.0010 | .0000/-.0004 |

|

|

.0003/.0011 | .0000/-.0005 |

| Tolerance • Metric | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 1–3 | 0,000/-0,010 | 0,000/-0,014 |

|

|

0,004/0,016 | 0,000/-0,008 |

|

|

0,006/0,021 | 0,000/-0,009 |

|

|

0,007/0,025 | 0,000/-0,011 |

|

|

0,008/0,029 | 0,000/-0,013 |

Forets pour trous profonds • Série B27_HPG • Nuance KCPK20™ • Arrosage central • Diamètres de foret 3–16mm • Métrique

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||

| Cutting Speed

|

Metric | ||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | |||

| P | 0 | 100 | 100 | 125 | mm/r | 0,13–0,15 | 0,14–0,16 | 0,15–0,21 | 0,19–0,26 | 0,21–0,31 | 0,26–0,36 | 0,30–0,41 | 0,34–0,46 |

| 1 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 2 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 80 | 95 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 4 | 80 | 90 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 5 | 60 | 80 | 90 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| 6 | 60 | 70 | 80 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| M | 1 | 40 | 50 | 60 | mm/r | 0,04–0,08 | 0,06–0,12 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | 0,14–0,19 |

| 2 | 30 | 40 | 50 | mm/r | 0,04–0,08 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| 3 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| K | 1 | 80 | 100 | 120 | mm/r | 0,15–0,19 | 0,17–0,20 | 0,19–0,26 | 0,24–0,32 | 0,27–0,40 | 0,32–0,45 | 0,38–0,52 | 0,45–0,59 |

| 2 | 80 | 90 | 100 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 60 | 90 | 120 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||

| Material

|

Cutting Speed

|

Inch | |||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | .551 | 5/8 .625 | |||

| P | 0 | 330 | 330 | 410 | IPR | .005–.006 | .006–.006 | .006–.008 | .008–.010 | .008–.012 | .010–.014 | .012–.016 | .013–.018 |

| 1 | 300 | 330 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 2 | 300 | 330 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 3 | 260 | 310 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 4 | 260 | 300 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 5 | 200 | 260 | 300 | IPR | .001–.004 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .005–.009 | .006–.009 | |

| 6 | 200 | 230 | 260 | IPR | .001–.004 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .005–.009 | .006–.009 | |

| M | 1 | 130 | 160 | 200 | IPR | .002–.003 | .002–.005 | .003–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | .006–.008 |

| 2 | 100 | 130 | 160 | IPR | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | |

| 3 | 100 | 130 | 160 | IPR | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | |

| K | 1 | 260 | 330 | 390 | IPR | .006–.008 | .007–.008 | .008–.010 | .009–.013 | .011–.016 | .013–.018 | .015–.021 | .018–.023 |

| 2 | 260 | 300 | 330 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 3 | 200 | 300 | 390 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||

| Cutting Speed

|

Metric | ||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material

|

Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | ||

| P | 0 | 100 | 100 | 125 | mm/r | 0,13–0,15 | 0,14–0,16 | 0,15–0,21 | 0,19–0,26 | 0,21–0,31 | 0,26–0,36 | 0,30–0,41 | 0,34–0,46 |

| 1 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 2 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 80 | 95 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 4 | 80 | 90 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 5 | 60 | 80 | 90 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| 6 | 60 | 70 | 80 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| M | 1 | 40 | 50 | 60 | mm/r | 0,04–0,08 | 0,06–0,12 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | 0,14–0,19 |

| 2 | 30 | 40 | 50 | mm/r | 0,04–0,08 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| 3 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| K | 1 | 80 | 100 | 120 | mm/r | 0,15–0,19 | 0,17–0,20 | 0,19–0,26 | 0,24–0,32 | 0,27–0,40 | 0,32–0,45 | 0,38–0,52 | 0,45–0,59 |

| 2 | 80 | 90 | 100 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 60 | 90 | 120 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |