Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client

Modifier le compte

Compte de livraison

Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

-

Notifications

Mark all as read - Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Kennametal à votre service

Support Clients

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution: {{SolutionName}}- Produits

- /

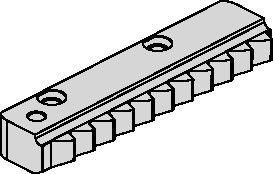

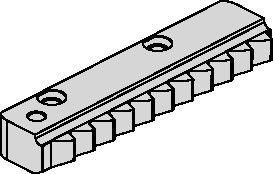

- TM40-NPT

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

TM40-NPT

TM40 • Plaquettes indexables