Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client

Modifier le compte

Compte de livraison

Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

-

Notifications

Mark all as read - Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Coup d'envoi de l'année 2024 avec d'incroyables économies sur les outils de perçage.

Achetez maintenant

Kennametal à votre service

Support Clients

Article(s)

ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution: {{SolutionName}}- Produits

- /

- Outils d’usinage des métaux

- /

- Filetage

- /

- Fraisage de filetage

- /

- TM40

- /

- Parallel Thread Mills

- /

- TM40 Parallel Cutter inch

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

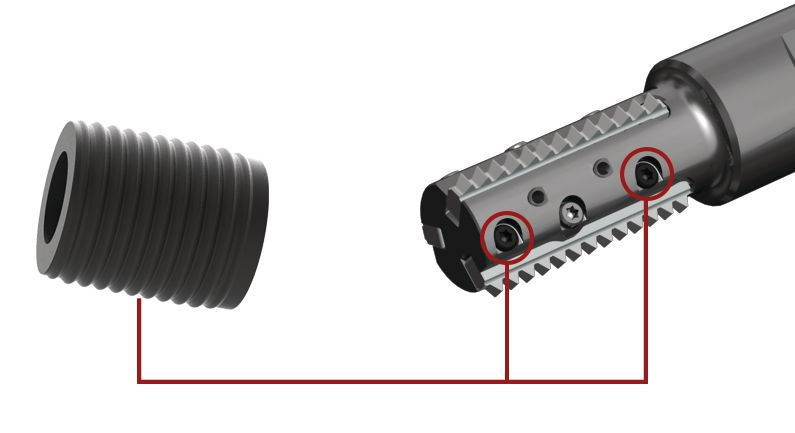

TM40 Parallel Cutter inch

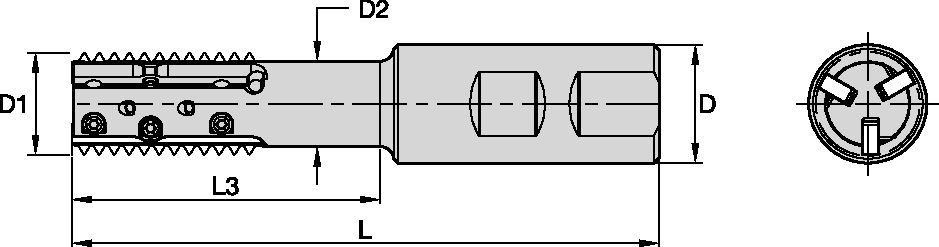

TM40 • Weldon® Shank • Parallel Threads

Features and benefits

- .870–1.180" cutting diameter range.

- For internal and external threading on most types of workpiece materials.

- One tool is used for both right- and left-hand threads.

- All cutters have through-coolant capability.

- Utilizes inserts with various profiles and pitches.

| Thread Application per Toolholder | ||||||

| min thread Ø | ||||||

| toolholder | D1 | ISO (coarse) | ISO (fine) | UN/UNF/UNEF/UNS | BSF | BSP(G) |

| TM40D087L169Z3 | .870 | M27 x 3 | M24 x 1; M24 x 1.5;

|

1 11/16–8UN; 1–9UN;

|

1–11; 1–12;

|

3/4–14 |

| TM40D087L256Z3 | .870 | M27 x 3 | M24 x 1; M24 x 1.5;

|

1 11/16–8UN; 1–9UN;

|

1–11; 1–12;

|

3/4–14 |

| TM40D118L215Z4 | 1.180 | – | M32 x 1; M32 x 1.5;

|

1 3/8–8UN; 1 3/8–9UN;

|

1 3/8–11; 1 3/8–12;

|

1–11 |

| TM40D118L315Z3 | 1.180 | – | M32 x 1; M32 x 1.5;

|

1 3/8–8UN; 1 3/8–9UN;

|

1 3/8–11; 1 3/8–12;

|

1–11 |

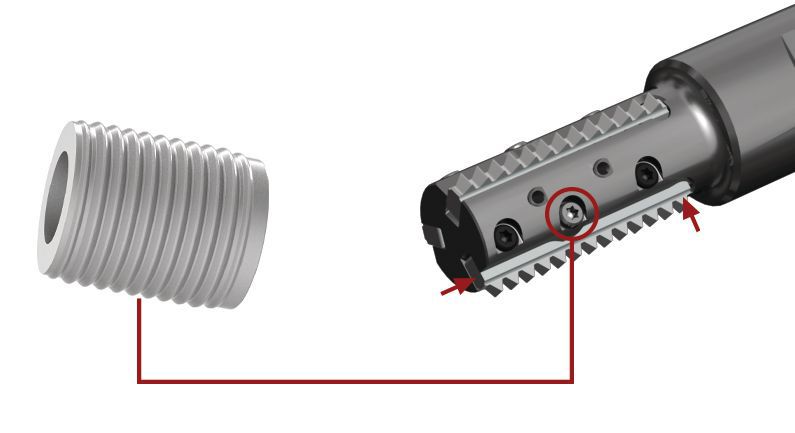

| 2 Step Clamping System |

| Step 1. Location Screw |

<="" td="" /> <="" td="" /> |

| Step 2. Clamping Screw (2) |

<="" td="" /> <="" td="" /> |