Product Similar To:

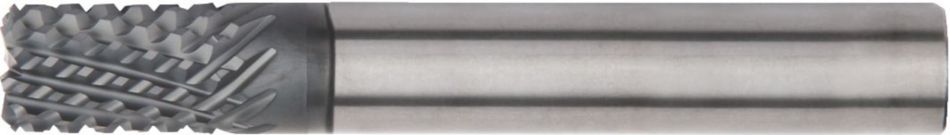

KenCut™ CF • CBDB • Chamfered • 12 Flutes • Plain Shank • Metric

KenCut™ CF Solid Carbide End Mill for CFRP

Material Number4137475

ISO Catalog IDCBDB0600AXASANSI Catalog IDCBDB0600AXAS

- N Non-Ferrous

- C CFRP Materials

Flute Configuration: 12

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Helix Angle: 15°

Corner Style: Corner Chamfer

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4137475 |

| ISO Catalog ID | CBDB0600AXAS |

| ANSI Catalog ID | CBDB0600AXAS |

| Grade | KCN05 |

| Adapter Style Machine Side | Straight-Cylindrical |

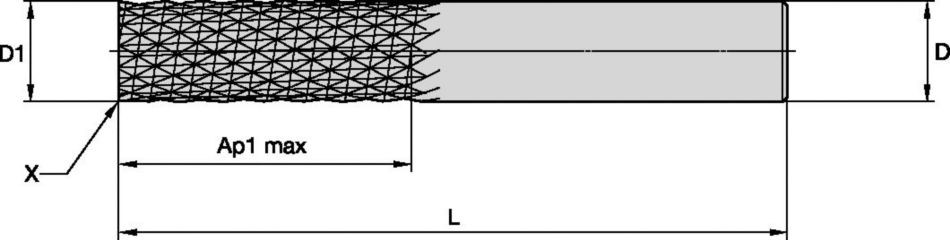

| [D1] Effective Cutting Diameter | 6 mm |

| [D1] Effective Cutting Diameter | 0.2362 in |

| [D] Adapter / Shank / Bore Diameter | 6 mm |

| [D] Adapter / Shank / Bore Diameter | 0.2362 in |

| [AP1MAX] 1st Maximum Cutting Depth | 18 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.709 in |

| [L] Overall Length | 63 mm |

| [L] Overall Length | 2.48 in |

| [BCH] Corner Chamfer Width | 0.508 mm |

| [BCH] Corner Chamfer Width | 0.02 in |

| [Z] Number of Flutes | 12 |

Workpiece Materials

- Non-Ferrous

- CFRP Materials

Uses and application

Flute Configuration: 12

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Helix Angle: 15°

Corner Style: Corner Chamfer

Grades

KCN05

High-performance grade A pure, diamond-coated carbide for milling CFRP and graphite. It is a very tough and wear-resistant grade.

Features and benefits

- Solid carbide end mill for carbon fibre reinforced parts maching (CFRP).

- Solid carbide end mill for composite and fibre glass machining.

- Bur style router for highest material removal rates and superior surface quality.

- Ideal for trimming CFRP and fibre glass. For slotting and profiling suitable.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

|  |  | ||||||||

| Side Milling (A) and Slotting (B) |  | Рекомендуемая подача на зуб (fz = мм/зуб) для обработки уступов (A). Для прорезания пазов (B) подачу fz уменьшите на 20%. | ||||||||

| A | B | Cutting Speed | D1 | |||||||

| Material | ap | ae | ap | Min | Max | mm | 6,0 | 10,0 | 12,0 | |

| C | 1 | Ap1 max | 0,2 x D | 1 x D | 100 | 150 | fz | 0,150 | 0,250 | 0,300 |

Tolerance

| End Mill Tolerances | |||

| D1 | tolerance | D | tolerance h6 + / - |

| All | +0/-0,05 | ≤3 | +0/-0,006 |

| +0/-0,008 | |||

| +0/-0,009 | |||

| +0/-0,011 | |||

| +0/-0,013 | |||

I have read and accepted the Terms & Conditions of use