Product Similar To :

7792VXD12 Series • Carbide Insert • XDLT-D721 • Medium Machining

High-feed copy milling insert with four cutting edges, precision ground.

Material Number5656252

ISO Catalog IDXDLT120508ERD721ANSI Catalog IDXDLT120508ERD721

- K Cast Iron

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5656252 |

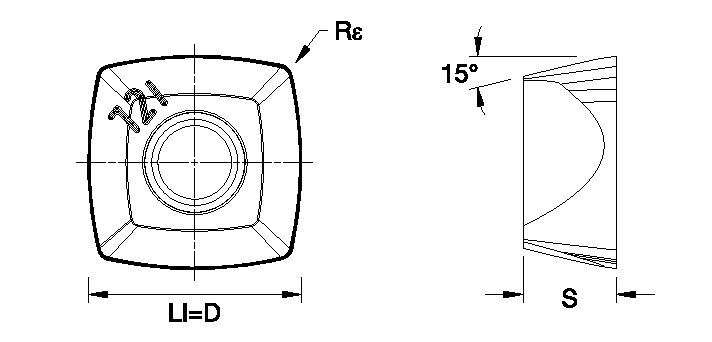

| ISO Catalog ID | XDLT120508ERD721 |

| ANSI Catalog ID | XDLT120508ERD721 |

| Grade | GH2 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [LI] Insert Length | 12.7 mm |

| [LI] Insert Length | 0.5 in |

| [S] Insert Thickness | 5.556 mm |

| [S] Insert Thickness | 0.2187 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.04 mm |

| Average Chip Thickness [HM] | 0.0016 in |

| [RT] Theoretical Corner Radius Programing | 2.5 mm |

| [RT] Theoretical Corner Radius Programing | 0.098 in |

Workpiece Materials

- Cast Iron

- Non-Ferrous

Grades

GH2

Uncoated, fine grained carbide grade with good strength. GH is suitable for machining of aluminum and non-ferrous materials. Also a good choice for cast iron for medium toughness requirements. This grade can be used both wet and dry and is designed for light and general machining.

Features and benefits

- Precision ground insert for best surface finish

- Single-sided copy milling insert for machining of steels, stainless steel and high-temperature alloys

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide • IC 12

| 7792 Series • IC12 • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | ...M41 | KCPM40 | …M41 | KCPM40 | …GP | KCPM40 |

| P3-P4 | ...M41 | KCPM40 | …D411 | SP6519 | …D41 | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| K3 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| H1 | …M | KCKP10 | …M | KCKP10 | …D | KCPM40 |

I have read and accepted the Terms & Conditions of use