Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Threading

- /

- Carbide Tapping

- /

- HP Carbide Taps

- /

- T321 • Form D Plug Chamfer • Through Coolant • Metric

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

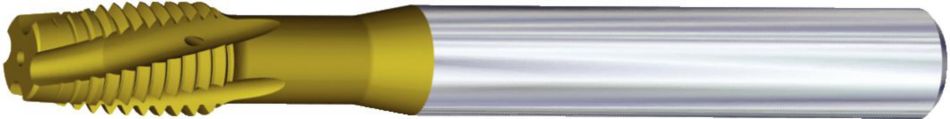

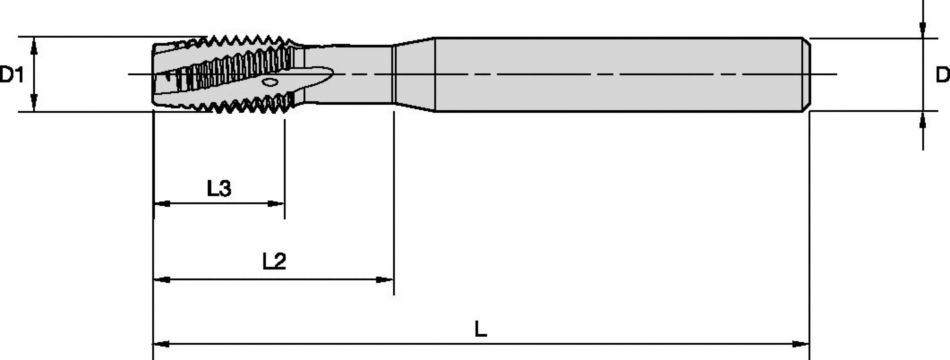

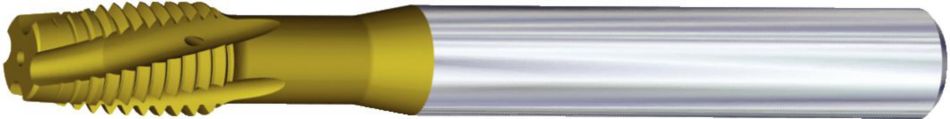

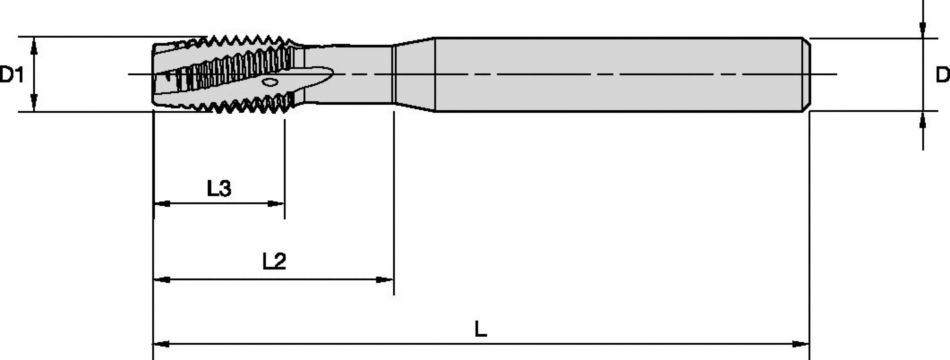

T321 • Form D Plug Chamfer • Through Coolant • Metric

Beyond™ Solid Carbide Left-Hand Spiral-Flute, Right-Hand Cut Taps • Through Holes

Features and benefits

- KC7542 TiAlN + TiN for steel.

Uses and application

Tapping: Through Hole

Class of Fit: 6HX

Chamfer Form D (3.5–5)

Tapping: Through Coolant

HM

Manufacturer’s Specs: M

Manufacturer’s Specs: MF

Tapping Helix Angle: L15°

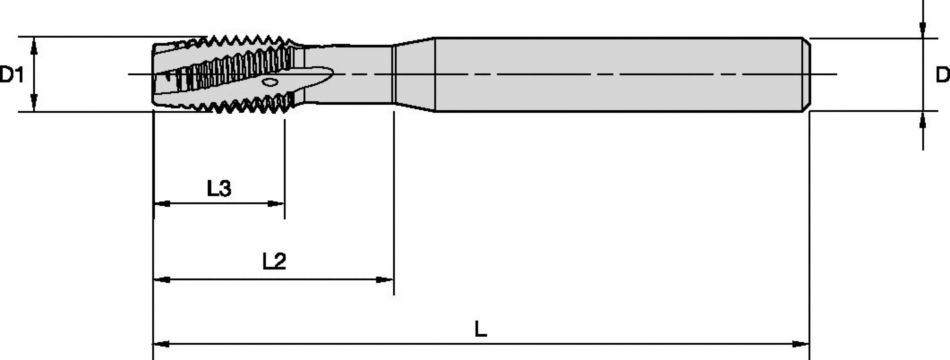

| shank tolerance | |

| D | tolerance h6 + / - |

| 6 | +0, -0,008 |

| 8

|

+0, -0,009 |

| 12

|

+0, -0,011 |

| shank tolerance | |

| D | tolerance h6 + / - |

| .250–.375 | +0, -.0004 |

| .438–.625 | +0, -.0004 |