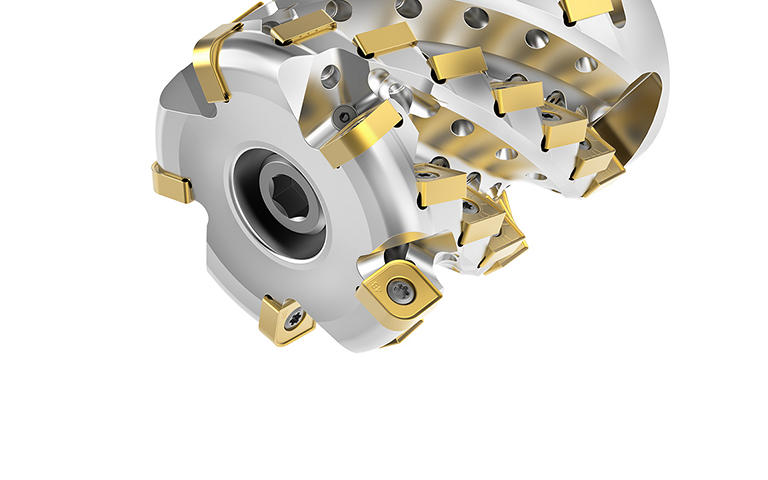

Up to 8 cutting edges per insert. That’s helical milling at the lowest possible cost-per-edge.

HARVI Ultra 8X helical milling cutters are designed to deliver the highest metal removal rates (MRR), especially in high-temperature alloys.

Lead inserts in various corner radii available, matching the needs of the aerospace industry.

HARVI Ultra 8x Taper Flange Adapters achieve maximum tool stiffness and maximum tool life.

Ideal for machines specifically designed to produce airframe structural parts.