ようこそ

設定をご確認ください

設定の更新

提案製品

Product Family suggestions

ソリューション編集

ソリューション追加

ソリューション名: {{SolutionName}}- 製品

- /

- 金属加工工具

- /

- 旋削加工

- /

- 溝入れと突っ切り

- /

- 溝加工

- /

- Beyond Evolution

- /

- Beyond Evolution Inserts

- /

- Square Shoulder Inserts

- /

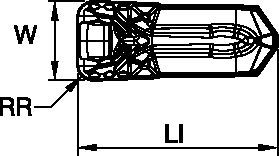

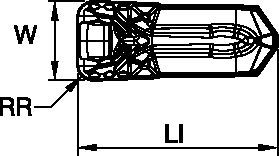

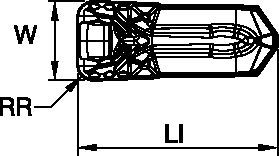

- Beyond™ Evolution™ • 溝入れインサート • GUP形状 • 精密研磨 • インチ

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

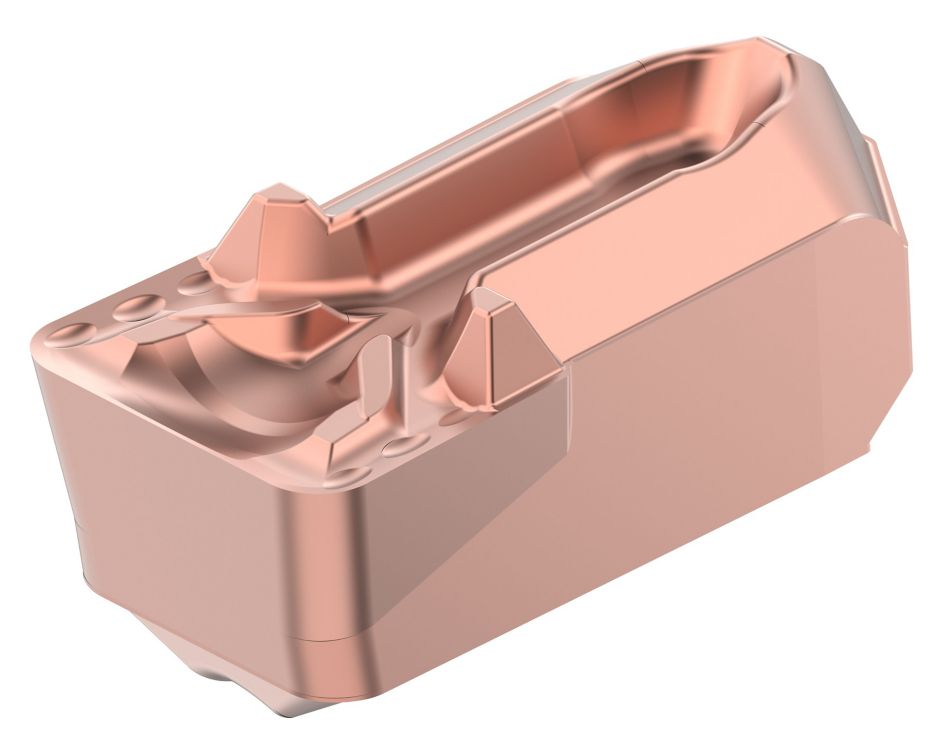

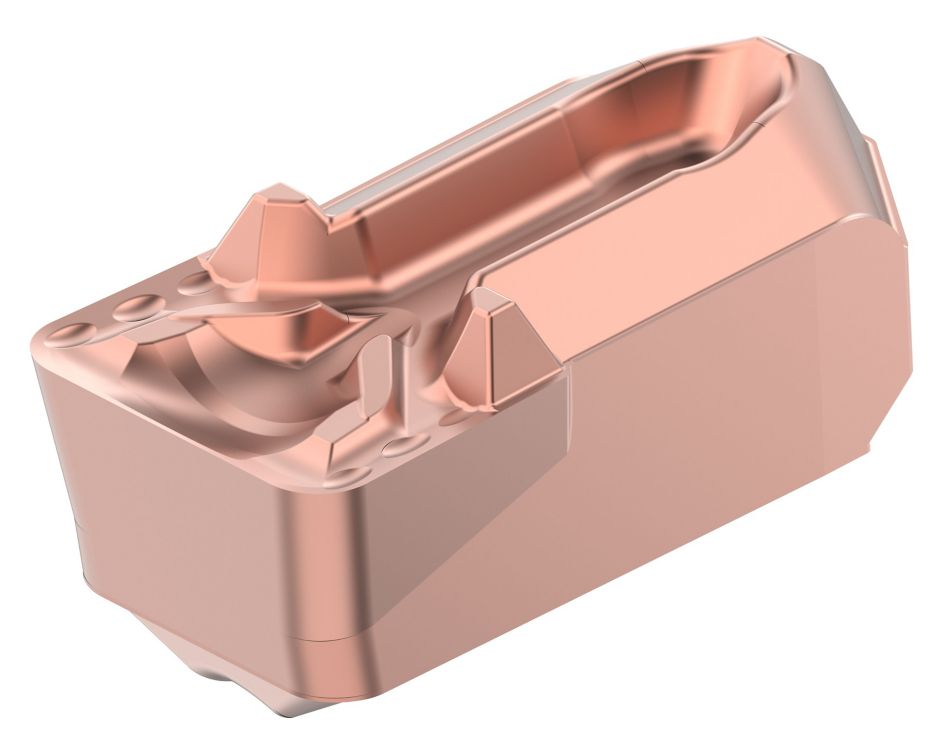

Beyond™ Evolution™ • 溝入れインサート • GUP形状 • 精密研磨 • インチ

溝入れ加工および突っ切り加工 • 超硬インサート

特徴と利点

- ポジのチップブレーカーで切削抵抗を低減

- 側面の旋削作業での切り屑排出のために設計されたブレーカー形状

- あらゆる被削材に対する高い性能を発揮

- さらに精密な幅と優れた再現性