ようこそ

設定をご確認ください

設定の更新

提案製品

Product Family suggestions

ソリューション編集

ソリューション追加

ソリューション名: {{SolutionName}}- 製品

- /

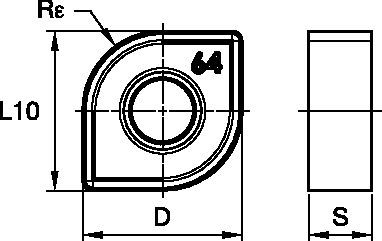

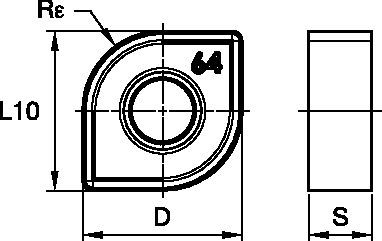

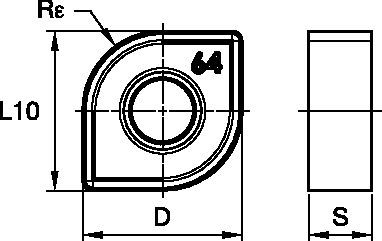

- HARVI™ Ultra 8X • インサート • IC10 • SNHJ10-GDH • リード列のみ

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

HARVI™ Ultra 8X • インサート • IC10 • SNHJ10-GDH • リード列のみ

HARVI™ Ultra 8X • Inserts • IC10 • GDH • LEAD ROW ONLY

インサート選択の手引き

| HARVI™ Ultra 8X • Insert Selection Guide I | ||||||

| Material Group | Light

|

General

|

Heavy

|

|||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear

|

<="" td=""> <="" td=""> | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..LEH | KCSM40 | .E..LEH | KCSM40 | .S..GDH | KCSM40 |

| P3–P4 | .E..LEH | KCSM40 | .E..LEH | KCSM40 | .S..GDH | KCSM40 |

| P5–P6 | .E..LEH | KCSM40 | .E..LEH | KCSM40 | .S..GDH | KCSM40 |

| M1–M2 | .E..LEH | KCSM40 | .E..LEH | KCSM40 | .S..GDH | KCSM40 |

| M3 | .E..LEH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..LEH | KCSM40 | .E..LEH | KCSM40 | .S..GDH | KCSM40 |

| S3 | .E..LEH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| S4 | .E..LEH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| H1 | – | – | – | – | – | – |

| HARVI™ Ultra 8X • Insert Selection Guide II - using inserts KSSM8+ (SNPJ12-GD) | ||||||

| Material Group | Light

|

General

|

Heavy

|

|||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear

|

<="" td=""> <="" td=""> | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GD | KCPM40 |

| P3–P4 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GD | KCPM40 |

| P5–P6 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GD | KCPM40 |

| M1–M2 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GD | KCPM40 |

| M3 | .S..GD | KCPK30 | .S..GD | KCPK30 | .S..GD | KCPM40 |

| K1–K2 | .S..GD | KCK20B | .S..GD | KCK20B | .S..GD | KCK15 |

| K3 | .S..GD | KCK20B | .S..GD | KCK20B | .S..GD | KCK20B |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Insert Selection Guide

| Material Group | Light

|

General

|

Heavy

|

|||

| (Light geometry) | (Strong geometry) | |||||

| wear

|

<="" td=""> <="" td=""> | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| M1–M2 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| M3 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| S3 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| S4 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| H1 | – | – | – | – | – | – |

推奨送り量の開始値 [mm]

| HARVI™ Ultra 8X • Recommended Starting Feeds [mm/th] | ||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||

| 10% | 20% | 30% | 40–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| HARVI Ultra 8X - SNHJ....E..LEH | 0.09 | 0.17 | 0.23 | 0.07 | 0.13 | 0.18 | 0.06 | 0.11 | 0.15 | 0.06 | 0.10 | 0.14 |

| HARVI Ultra 8X - SNHJ....S..GDH | 0.13 | 0.20 | 0.31 | 0.10 | 0.15 | 0.23 | 0.09 | 0.13 | 0.20 | 0.08 | 0.12 | 0.18 |

| KSSM8+ - SNPJ…..S..GD | 0,17 | 0,37 | 0,59 | 0,13 | 0,27 | 0,44 | 0,11 | 0,24 | 0,38 | 0,10 | 0,22 | 0,35 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||||||||||

| Light

|

General

|

Heavy

|

推奨送り量の開始値 [mm]

| Light

|

General

|

Heavy

|

| Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||||||||

| Material | Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| P5 | .S..GDH | – | – | – | 0,18 | 0,29 | 0,45 | 0,16 | 0,26 | 0,40 | 0,13 | 0,21 | 0,33 | 0,07 | 0,12 | 0,18 | .S..GDH |

| P6 | .S..GDH | – | – | – | 0,18 | 0,24 | 0,38 | 0,16 | 0,22 | 0,34 | 0,13 | 0,18 | 0,27 | 0,07 | 0,10 | 0,15 | .S..GDH |

| M1 | .S..GDH | – | – | – | 0,18 | 0,28 | 0,43 | 0,16 | 0,25 | 0,38 | 0,13 | 0,20 | 0,31 | 0,07 | 0,11 | 0,17 | .S..GDH |

| M2 | .S..GDH | – | – | – | 0,18 | 0,28 | 0,43 | 0,16 | 0,25 | 0,38 | 0,13 | 0,20 | 0,31 | 0,07 | 0,11 | 0,17 | .S..GDH |

| M3 | .S..GDH | – | – | – | 0,18 | 0,24 | 0,38 | 0,16 | 0,22 | 0,34 | 0,13 | 0,18 | 0,27 | 0,07 | 0,10 | 0,15 | .S..GDH |

| S1 | .S..GDH | – | – | – | 0,18 | 0,20 | 0,30 | 0,16 | 0,17 | 0,27 | 0,13 | 0,14 | 0,22 | 0,07 | 0,08 | 0,12 | .S..GDH |

| S2 | .S..GDH | – | – | – | 0,18 | 0,20 | 0,30 | 0,16 | 0,17 | 0,27 | 0,13 | 0,14 | 0,22 | 0,07 | 0,08 | 0,12 | .S..GDH |

| S3 | .S..GDH | – | – | – | 0,18 | 0,23 | 0,35 | 0,16 | 0,20 | 0,31 | 0,13 | 0,17 | 0,26 | 0,07 | 0,09 | 0,14 | .S..GDH |

| S4 | .S..GDH | – | – | – | 0,18 | 0,28 | 0,43 | 0,16 | 0,25 | 0,38 | 0,13 | 0,20 | 0,31 | 0,07 | 0,11 | 0,17 | .S..GDH |

Recommended Starting Feeds [IPT]

| HARVI™ Ultra 8X • Recommended Starting Feeds [IPT] | ||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||

| 10% | 20% | 30% | 40–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| HARVI Ultra 8X - SNHJ....E..LEH | 0.004 | 0.007 | 0.008 | 0.003 | 0.005 | 0.006 | 0.002 | 0.004 | 0.005 | 0.002 | 0.004 | 0.005 |

| HARVI Ultra 8X - SNHJ....S..GDH | 0.005 | 0.008 | 0.010 | 0.004 | 0.006 | 0.008 | 0.003 | 0.005 | 0.007 | 0.003 | 0.005 | 0.006 |

| KSSM8+ - SNPJ…..S..GD | 0.007 | 0.015 | 0.023 | 0.005 | 0.011 | 0.017 | 0.004 | 0.009 | 0.015 | 0.004 | 0.009 | 0.014 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||||||||||

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Light

|

General

|

Heavy

|

| Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||||||||

| Material | Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| P5 | .S..GDH | – | – | – | .007 | .012 | .018 | .006 | .010 | .016 | .005 | .008 | .013 | .003 | .005 | .007 | .S..GDH |

| P6 | .S..GDH | – | – | – | .007 | .010 | .015 | .006 | .009 | .013 | .005 | .007 | .011 | .003 | .004 | .006 | .S..GDH |

| M1 | .S..GDH | – | – | – | .007 | .011 | .017 | .006 | .010 | .015 | .005 | .008 | .012 | .003 | .004 | .007 | .S..GDH |

| M2 | .S..GDH | – | – | – | .007 | .011 | .017 | .006 | .010 | .015 | .005 | .008 | .012 | .003 | .004 | .007 | .S..GDH |

| M3 | .S..GDH | – | – | – | .007 | .010 | .015 | .006 | .009 | .013 | .005 | .007 | .011 | .003 | .004 | .006 | .S..GDH |

| S1 | .S..GDH | – | – | – | .007 | .008 | .012 | .006 | .007 | .011 | .005 | .006 | .009 | .003 | .003 | .005 | .S..GDH |

| S2 | .S..GDH | – | – | – | .007 | .008 | .012 | .006 | .007 | .011 | .005 | .006 | .009 | .003 | .003 | .005 | .S..GDH |

| S3 | .S..GDH | – | – | – | .007 | .009 | .014 | .006 | .008 | .012 | .005 | .007 | .010 | .003 | .004 | .006 | .S..GDH |

| S4 | .S..GDH | – | – | – | .007 | .011 | .017 | .006 | .010 | .015 | .005 | .008 | .012 | .003 | .004 | .007 | .S..GDH |

推奨切削速度の開始値 [m/min]

| HARVI™ Ultra 8X • Recommended Starting Speed [m/min] | |||||||||||||||||||

| Grade | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM40 | |||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | – | – | – | 295 | 260 | 245 | 350 | 320 | 300 |

| 2 | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | – | – | – | 250 | 215 | 180 | 300 | 270 | 220 | |

| 3 | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | – | – | – | 230 | 195 | 160 | 280 | 240 | 195 | |

| 4 | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | – | – | – | 205 | 170 | 135 | 240 | 205 | 165 | |

| 5 | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | – | – | – | 170 | 155 | 135 | 200 | 180 | 160 | |

| 6 | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | – | – | – | 150 | 115 | 90 | 180 | 140 | 100 | |

| M | 1 | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 | 260 | 210 | 185 |

| 2 | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | 235 | 180 | 145 | |

| 3 | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | 175 | 145 | 110 | |

| K | 1 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 360 | 290 | 245 | – | – | – | – | – | – |

| 2 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 230 | 195 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 210 | 175 | 140 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 50 | 40 | 25 |

| 2 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 55 | 40 | 25 | |

| 3 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 65 | 45 | 30 | |

| 4 | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | 75 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||

推奨切削速度の開始値 [m/min]

| Material Group | KC725M | KCSM40 | |||||

| P | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

5 | 120 | 110 | 95 | 250 | 138 | 125 |

|

|

6 | 105 | 80 | 65 | 225 | 127 | 115 |

| M | 1 | 135 | 120 | 110 | 270 | 127 | 115 |

|

|

2 | 125 | 105 | 90 | 270 | 127 | 115 |

|

|

3 | 90 | 80 | 65 | 200 | 88 | 80 |

| K | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

| N | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

| S | 1 | 30 | 25 | 20 | 60 | 25 | 23 |

|

|

2 | 30 | 25 | 20 | 50 | 23 | 21 |

|

|

3 | 35 | 30 | 20 | 55 | 26 | 24 |

|

|

4 | 45 | 35 | 25 | 80 | 39 | 35 |

| H | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

| HARVI™ Ultra 8X • Recommended Starting Speed [SFM] | |||||||||||||||||||

| Grade | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM40 | |||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 855 | 755 | 705 | – | – | – | 1495 | 1295 | 1215 | – | – | – | 970 | 855 | 805 | 1150 | 1050 | 985 |

| 2 | 720 | 625 | 525 | – | – | – | 920 | 835 | 755 | – | – | – | 820 | 705 | 590 | 985 | 885 | 720 | |

| 3 | 655 | 560 | 460 | – | – | – | 835 | 755 | 675 | – | – | – | 755 | 640 | 525 | 920 | 785 | 640 | |

| 4 | 590 | 490 | 395 | – | – | – | 740 | 605 | 525 | – | – | – | 675 | 560 | 445 | 785 | 675 | 540 | |

| 5 | 490 | 445 | 395 | – | – | – | 625 | 560 | 490 | – | – | – | 560 | 510 | 445 | 655 | 590 | 525 | |

| 6 | 425 | 330 | 260 | – | – | – | 525 | 445 | 360 | – | – | – | 490 | 375 | 295 | 590 | 460 | 330 | |

| M | 1 | 560 | 490 | 445 | – | – | – | 675 | 605 | 510 | – | – | – | 640 | 560 | 510 | 855 | 690 | 605 |

| 2 | 510 | 425 | 360 | – | – | – | 605 | 525 | 460 | – | – | – | 575 | 490 | 410 | 770 | 590 | 475 | |

| 3 | 375 | 330 | 260 | – | – | – | 475 | 425 | 375 | – | – | – | 425 | 375 | 295 | 575 | 475 | 360 | |

| K | 1 | – | – | – | 1380 | 1265 | 1115 | 970 | 870 | 785 | 1180 | 950 | 805 | – | – | – | – | – | – |

| 2 | – | – | – | 1100 | 970 | 900 | 770 | 690 | 625 | 920 | 755 | 640 | – | – | – | – | – | – | |

| 3 | – | – | – | 920 | 820 | 755 | 640 | 575 | 525 | 690 | 575 | 460 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 165 | 130 | 80 |

| 2 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | |

| 3 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | |

| 4 | 165 | 150 | 100 | – | – | – | 165 | 150 | 115 | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||

Recommended Starting Speeds [SFM]

| Material Group | KC725M | KCSM40 | |||||

| P | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

5 | 390 | 355 | 315 | 820 | 450 | 410 |

|

|

6 | 340 | 265 | 210 | 740 | 415 | 375 |

| M | 1 | 450 | 390 | 355 | 885 | 415 | 375 |

|

|

2 | 410 | 340 | 290 | 885 | 415 | 375 |

|

|

3 | 300 | 265 | 210 | 655 | 290 | 260 |

| K | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

| N | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

| S | 1 | 90 | 80 | 65 | 195 | 90 | 75 |

|

|

2 | 90 | 80 | 65 | 165 | 90 | 70 |

|

|

3 | 120 | 90 | 65 | 180 | 105 | 80 |

|

|

4 | 145 | 120 | 80 | 260 | 150 | 115 |

| H | 1 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|