ようこそ

設定をご確認ください

設定の更新

提案製品

Product Family suggestions

ソリューション編集

ソリューション追加

ソリューション名: {{SolutionName}}- 製品

- /

- 金属加工工具

- /

- ねじ切り

- /

- HSSタッピング

- /

- HP HSS-E-PM Taps

- /

- T62_ HP Taps for Steel and Stainless Steel

- /

- T620 • メトリックDIN 376 • フォームDプラグ面取り • 風力エネルギー

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

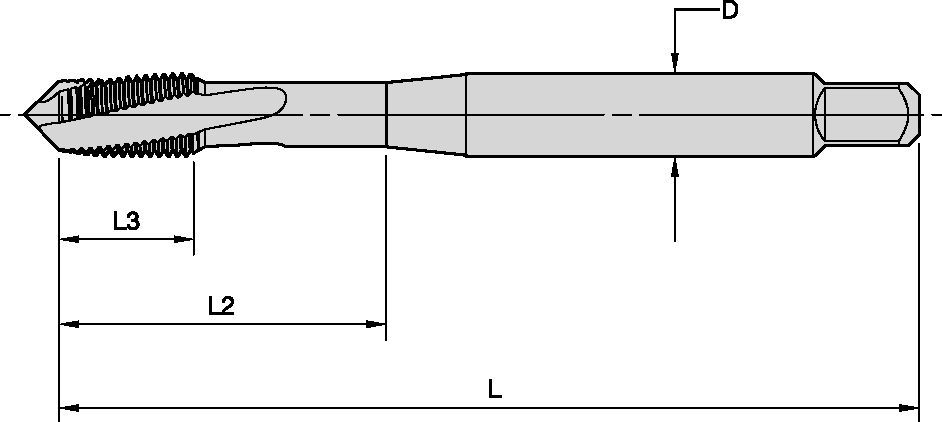

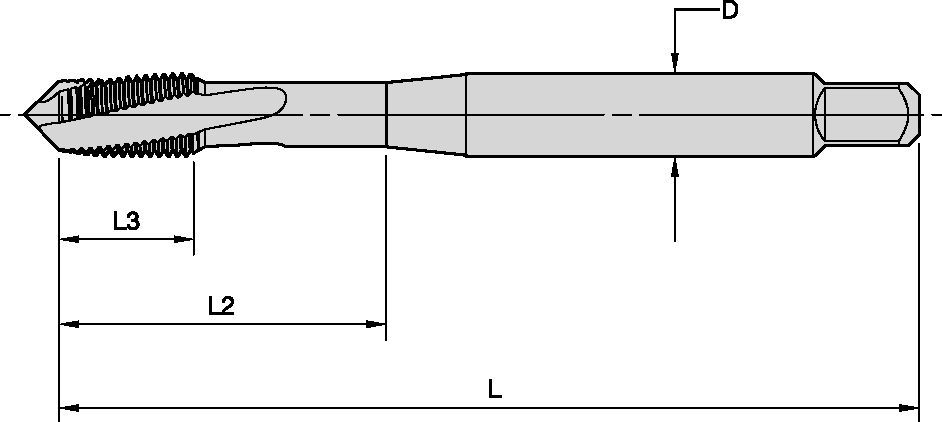

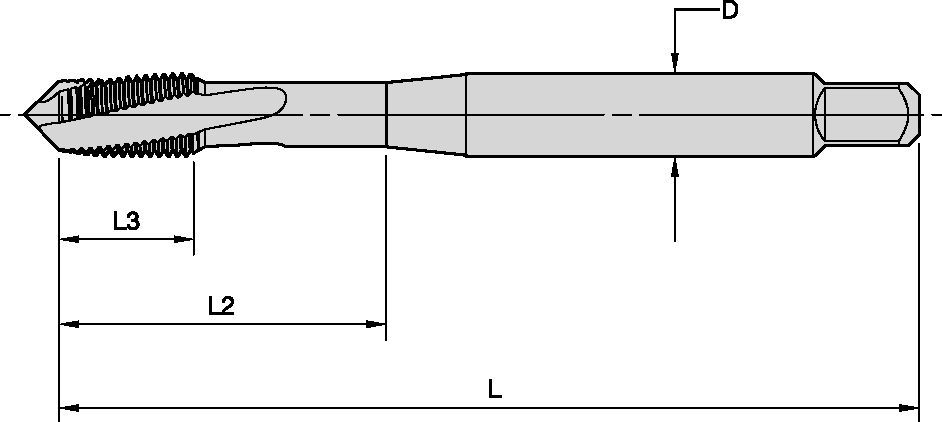

T620 • メトリックDIN 376 • フォームDプラグ面取り • 風力エネルギー

Beyond™左勝手スパイラルフルート、右勝手切削HSS-E-PMタップ • 貫通穴

特徴と利点

- KM6515 ステンレス鋼のタッピングにはTiN + CrC/C。

- KP6525 鋼のタッピングにはTiCN + TiN。

使用法と用途

タッピング:スルーホール

はめあい区分:6HX

DIN番号371

DIN番号374

DIN番号376

面取りフォームD(3.5~5)

HSS-E-PM

メーカー仕様:M

メーカー仕様:MF

タッピングねじれ角:L15°