-

P Steel (44)

-

P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS (44)

-

P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS (44)

-

P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS (44)

-

P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS (44)

-

P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS (44)

-

P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS (44)

-

P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS (44)

-

-

M Stainless Steel (44)

-

M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS (44)

-

M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS (44)

-

M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS (44)

-

-

K Cast Iron (39)

-

K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS (39)

-

K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS (39)

-

K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS (39)

-

-

N Non-Ferrous Materials (39)

-

N1Wrought Aluminum (39)

-

N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2% (39)

-

N3High-Silicon Aluminum Alloys Si >12.2% (39)

-

N4Copper, Brass, Zinc-based on machinability index range of 70-100 (39)

-

N5Nylon, Plastics, Rubbers, Phenolics, Resins, Fiberglass (39)

-

N6Carbon, Graphite Composites, CFRP (39)

-

N7MMC's (39)

-

-

S High-Temp Alloys (44)

-

S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS (44)

-

S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS (44)

-

S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS (44)

-

S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS (44)

-

-

H Hardened Materials (39)

-

H1Hardened Materials 44-48 HRC (39)

-

H2Hardened Materials 48-55 HRC (39)

-

H3Hardened Materials 56-60 HRC (39)

-

H4Hardened Materials >60 HRC (39)

-

-

C CFRP Materials (39)

-

C1CFRP, CFRP / CFRP (39)

-

C2CFRP / Aluminium CFRP / Non-Ferrous (39)

-

-

Blind & Cross Hole Finishing (71)

-

Blind Hole Finishing (71)

-

Through & Cross Hole Finishing (71)

-

Through Hole Finishing (71)

-

Heavily Interrupted Cut (39)

-

Lightly Interrupted Cut (44)

-

Smooth Cut (44)

-

90.0 (12)

-

91.0 (8)

-

92.0 (23)

-

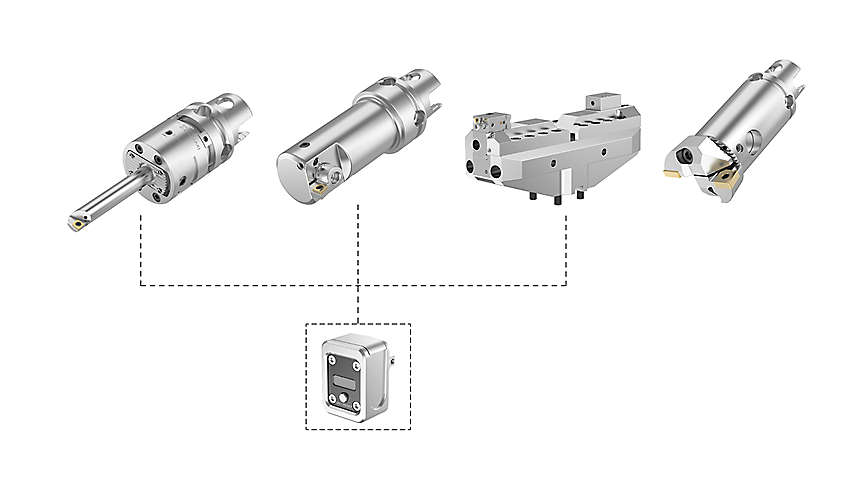

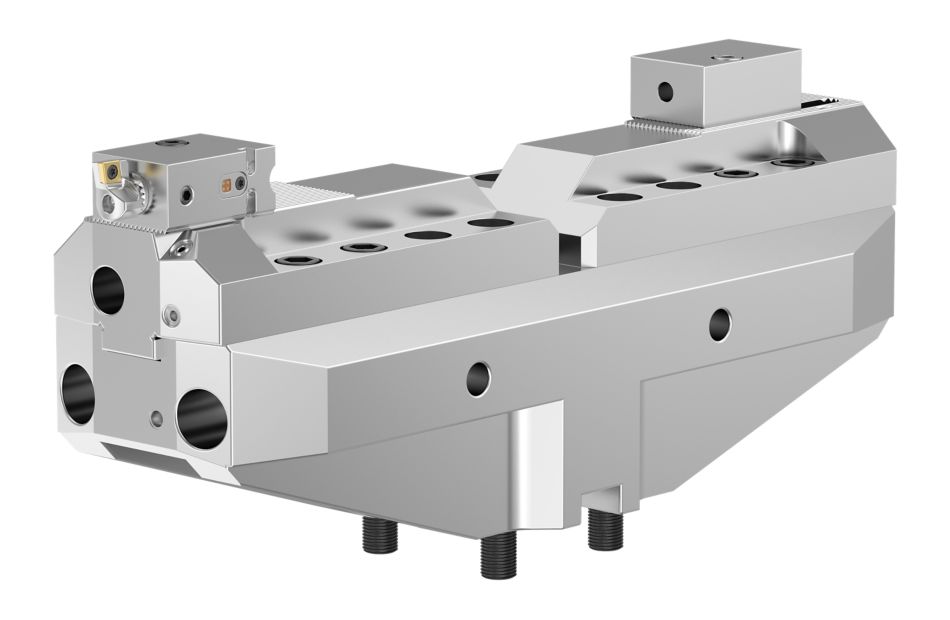

E-BORE Boring Bar (21)

-

1.0 (17)

-

2.0 (17)

-

3.0 (5)

-

4.0 (17)

-

0.36 in (1)

-

0.395 in (1)

-

0.496 in (3)

-

0.574 in (1)

-

0.576 in (1)

-

0.592 in (1)

-

0.65 in (2)

-

0.669 in (3)

-

0.811 in (1)

-

0.816 in (2)

-

1.0 in (1)

-

1.205 in (1)

-

1.209 in (3)

-

1.772 in (1)

-

1.891 in (1)

-

2.086 in (1)

-

2.087 in (1)

-

2.165 in (1)

-

2.265 in (1)

-

2.282 in (2)

-

2.479 in (1)

-

2.676 in (1)

-

2.677 in (1)

-

2.873 in (1)

-

3.071 in (1)

-

3.269 in (1)

-

3.661 in (2)

-

3.858 in (2)

-

4.449 in (2)

-

4.843 in (1)

-

5.63 in (1)

-

9.15 mm (1)

-

10.025 mm (1)

-

12.601 mm (3)

-

14.55 mm (1)

-

14.601 mm (1)

-

15.025 mm (1)

-

16.5 mm (2)

-

17.0 mm (3)

-

20.6 mm (1)

-

20.701 mm (2)

-

25.401 mm (1)

-

30.6 mm (1)

-

30.701 mm (3)

-

45.0 mm (1)

-

48.0 mm (1)

-

52.975 mm (1)

-

53.0 mm (1)

-

55.0 mm (1)

-

57.5 mm (1)

-

57.975 mm (2)

-

62.975 mm (1)

-

67.976 mm (1)

-

68.0 mm (1)

-

72.976 mm (1)

-

78.0 mm (1)

-

83.0 mm (1)

-

93.0 mm (2)

-

98.0 mm (2)

-

113.0 mm (2)

-

123.0 mm (1)

-

143.0 mm (1)

-

0.0 in (3)

-

0.001 in (32)

-

0.002 in (32)

-

0.004 in (44)

-

0.008 in (39)

-

0.016 in (39)

-

0.031 in (39)

-

0.047 in (10)

-

0.063 in (3)

-

0.0 mm (3)

-

0.025 mm (32)

-

0.05 mm (32)

-

0.1 mm (44)

-

0.2 mm (39)

-

0.4 mm (39)

-

0.8 mm (39)

-

1.201 mm (10)

-

1.6 mm (3)

-

0.0 mm (23)

-

0.0 in (23)

-

HCK10 (39)

-

HK1500 (32)

-

HK35 (36)

-

HT2 (39)

-

HTX (39)

-

HWK15 (39)

-

K10M (36)

-

K10P (36)

-

K10U (32)

-

K15U (32)

-

K20K (36)

-

K25M (29)

-

K313 (39)

-

K68 (39)

-

KB1345 (10)

-

KB1610 (32)

-

KB1630 (39)

-

KB5610 (32)

-

KB5625 (32)

-

KB5630 (32)

-

KB9610 (32)

-

KBH10 (32)

-

KBH20 (39)

-

KC5010 (39)

-

KC5025 (39)

-

KC5410 (39)

-

KC720 (39)

-

KC730 (39)

-

KC732 (39)

-

KC8050 (39)

-

KC810 (39)

-

KC850 (39)

-

KC9010 (32)

-

KC9025 (39)

-

KC910 (39)

-

KC9105 (39)

-

KC9110 (39)

-

KC9120 (32)

-

KC9125 (39)

-

KC9225 (39)

-

KC9240 (39)

-

KC9240NEW (39)

-

KC9315 (39)

-

KC9320 (39)

-

KC9325 (39)

-

KC935 (39)

-

KC950 (32)

-

KC990 (32)

-

KCD25 (39)

-

KCK05 (39)

-

KCK05B (32)

-

KCK15 (39)

-

KCK15B (39)

-

KCK20 (39)

-

KCK20B (39)

-

KCM15 (39)

-

KCM15B (39)

-

KCM25 (39)

-

KCM25B (39)

-

KCM25S (32)

-

KCM35 (39)

-

KCM35B (3)

-

KCP05 (39)

-

KCP05B (3)

-

KCP10 (39)

-

KCP10B (39)

-

KCP20S (32)

-

KCP25 (39)

-

KCP25B (39)

-

KCP25C (39)

-

KCP30 (39)

-

KCP30B (10)

-

KCS10 (39)

-

KCS10B (39)

-

KCS25S (32)

-

KCU10 (44)

-

KCU10B (39)

-

KCU25 (39)

-

KCU25B (39)

-

KD050 (32)

-

KD081 (32)

-

KD1400 (32)

-

KD1425 (32)

-

KN10S (32)

-

KT175 (32)

-

KT315 (39)

-

KT325 (39)

-

KTP10 (32)

-

KTP25S (32)

-

KU10 (32)

-

KU10T (39)

-

KU30T (39)

-

NL300 (7)

-

NL920 (7)

-

PB100 (29)

-

PB170 (36)

-

PB250 (36)

-

PB300 (29)

-

PD100 (39)

-

PD50 (36)

-

SP0PW3 (7)

-

SP4019 (7)

-

SPN3W1 (3)

-

THM (39)

-

THM-X (39)

-

TN1000 (29)

-

TN10P (39)

-

TN10U (39)

-

TN15M (39)

-

TN15U (32)

-

TN2000 (39)

-

TN20K (39)

-

TN20P (39)

-

TN30M (39)

-

TN4000 (32)

-

TN5015 (39)

-

TN5020 (39)

-

TN5105 (39)

-

TN5120 (39)

-

TN6010 (10)

-

TN6025 (3)

-

TN7005 (3)

-

TN7010 (39)

-

TN7015 (39)

-

TN7025 (39)

-

TN7035 (39)

-

TN7105 (39)

-

TN7110 (39)

-

TN7115 (39)

-

TN7125 (39)

-

TN7135 (39)

-

TN8025 (39)

-

TTI15 (32)

-

TTM (3)

-

TTR (39)

-

TTS (32)

-

TTX (3)

-

W00342 (7)

-

WBH10C (32)

-

WBH10P (32)

-

WBH10U (32)

-

WBH20P (10)

-

WBH25P (32)

-

WBH30P (3)

-

WBK45U (10)

-

WDN00U (32)

-

WDN25U (32)

-

WK05CT (39)

-

WK15CT (39)

-

WK20CT (39)

-

WM15CT (39)

-

WM25CT (39)

-

WP15CT (39)

-

WP20TT (29)

-

WP25CT (39)

-

WP35CT (10)

-

WS10PT (39)

-

WS25PT (32)

-

WU05PT (39)

-

WU10HT (39)

-

WU10PR (4)

-

WU10PT (39)

-

WU20HT (29)

-

WU25PT (39)

-

R (21)

-

N (22)

-

0.151 mm (1)

-

2.825 mm (2)

-

3.825 mm (1)

-

4.75 mm (1)

-

4.775 mm (3)

-

5.75 mm (2)

-

5.775 mm (1)

-

6.75 mm (2)

-

6.775 mm (2)

-

7.325 mm (1)

-

7.75 mm (1)

-

7.775 mm (2)

-

9.775 mm (1)

-

12.275 mm (1)

-

0.006 in (1)

-

0.111 in (2)

-

0.151 in (1)

-

0.187 in (1)

-

0.188 in (3)

-

0.226 in (2)

-

0.227 in (1)

-

0.266 in (2)

-

0.267 in (2)

-

0.289 in (1)

-

0.305 in (1)

-

0.306 in (2)

-

0.385 in (1)

-

0.483 in (1)

-

2.0 mm (1)

-

6.0 mm (2)

-

8.0 mm (2)

-

10.0 mm (4)

-

12.0 mm (3)

-

14.0 mm (4)

-

15.0 mm (1)

-

16.0 mm (3)

-

19.5 mm (1)

-

20.0 mm (1)

-

22.5 mm (1)

-

24.5 mm (1)

-

25.0 mm (1)

-

25.5 mm (1)

-

29.0 mm (2)

-

36.0 mm (2)

-

40.0 mm (1)

-

43.0 mm (1)

-

52.0 mm (1)

-

53.0 mm (1)

-

65.0 mm (2)

-

68.0 mm (1)

-

76.0 mm (1)

-

82.0 mm (1)

-

100.0 mm (1)

-

125.0 mm (1)

-

200.0 mm (2)

-

0.079 in (1)

-

0.237 in (2)

-

0.315 in (2)

-

0.394 in (4)

-

0.473 in (3)

-

0.551 in (4)

-

0.591 in (1)

-

0.63 in (3)

-

0.768 in (1)

-

0.787 in (1)

-

0.886 in (1)

-

0.965 in (1)

-

0.984 in (1)

-

1.004 in (1)

-

1.143 in (2)

-

1.417 in (2)

-

1.575 in (1)

-

1.693 in (1)

-

2.047 in (1)

-

2.087 in (1)

-

2.559 in (2)

-

2.677 in (1)

-

2.992 in (1)

-

3.228 in (1)

-

3.938 in (1)

-

4.921 in (1)

-

7.875 in (2)

-

0.315 in (2)

-

0.394 in (2)

-

0.473 in (4)

-

0.551 in (3)

-

0.63 in (4)

-

0.787 in (4)

-

0.906 in (1)

-

0.984 in (1)

-

1.024 in (1)

-

1.181 in (2)

-

1.457 in (2)

-

1.614 in (1)

-

1.732 in (1)

-

2.087 in (1)

-

2.126 in (1)

-

2.283 in (1)

-

2.598 in (2)

-

3.031 in (1)

-

3.269 in (1)

-

4.016 in (1)

-

4.055 in (1)

-

5.118 in (1)

-

5.984 in (1)

-

8.071 in (2)

-

40.158 in (2)

-

8.0 mm (2)

-

10.0 mm (2)

-

12.0 mm (4)

-

14.0 mm (3)

-

16.0 mm (4)

-

20.0 mm (4)

-

23.0 mm (1)

-

25.0 mm (1)

-

26.0 mm (1)

-

30.0 mm (2)

-

37.0 mm (2)

-

41.0 mm (1)

-

44.0 mm (1)

-

53.0 mm (1)

-

54.0 mm (1)

-

58.0 mm (1)

-

66.0 mm (2)

-

77.0 mm (1)

-

83.0 mm (1)

-

102.0 mm (1)

-

103.0 mm (1)

-

130.0 mm (1)

-

152.0 mm (1)

-

205.0 mm (2)

-

1020.0 mm (2)

-

E (21)

-

NEGATIVE-ZERO (21)

-

0.787 in (1)

-

0.906 in (1)

-

1.102 in (1)

-

1.104 in (1)

-

1.181 in (1)

-

1.298 in (1)

-

1.338 in (1)

-

1.574 in (1)

-

1.693 in (1)

-

1.695 in (1)

-

1.907 in (1)

-

2.165 in (1)

-

2.277 in (1)

-

2.757 in (2)

-

2.953 in (2)

-

3.543 in (2)

-

3.938 in (1)

-

4.724 in (1)

-

20.0 mm (1)

-

23.0 mm (1)

-

28.0 mm (1)

-

28.05 mm (1)

-

30.0 mm (1)

-

32.975 mm (1)

-

33.975 mm (1)

-

39.975 mm (1)

-

43.0 mm (1)

-

43.051 mm (1)

-

48.426 mm (1)

-

55.0 mm (1)

-

57.825 mm (1)

-

70.0 mm (2)

-

75.0 mm (2)

-

90.0 mm (2)

-

100.0 mm (1)

-

120.0 mm (1)

-

S (21)

-

C-DIAMOND/RHOMBIC 80 (39)

-

W-TRIGON 80 (4)

-

X-TRIGON 82 (1)

-

0.157 in (2)

-

0.197 in (2)

-

0.237 in (4)

-

0.276 in (3)

-

0.315 in (4)

-

0.394 in (4)

-

0.492 in (1)

-

0.591 in (1)

-

4.0 mm (2)

-

5.0 mm (2)

-

6.0 mm (4)

-

7.0 mm (3)

-

8.0 mm (4)

-

10.0 mm (4)

-

12.5 mm (1)

-

15.0 mm (1)

-

0.576 in (1)

-

0.63 in (3)

-

1.161 in (1)

-

1.772 in (1)

-

1.891 in (1)

-

2.677 in (1)

-

2.757 in (4)

-

2.835 in (2)

-

2.992 in (2)

-

3.228 in (1)

-

3.307 in (1)

-

3.346 in (4)

-

3.386 in (3)

-

3.543 in (1)

-

3.701 in (1)

-

3.938 in (1)

-

4.016 in (2)

-

4.094 in (2)

-

4.331 in (4)

-

4.488 in (1)

-

4.724 in (1)

-

5.118 in (2)

-

5.236 in (1)

-

5.433 in (2)

-

5.827 in (1)

-

6.299 in (1)

-

110 mm (4)

-

70 mm (4)

-

85 mm (4)

-

16 mm (3)

-

86 mm (3)

-

102 mm (2)

-

104 mm (2)

-

130 mm (2)

-

138 mm (2)

-

72 mm (2)

-

76 mm (2)

-

100 mm (1)

-

114 mm (1)

-

120 mm (1)

-

133 mm (1)

-

148 mm (1)

-

160 mm (1)

-

45 mm (1)

-

48 mm (1)

-

68 mm (1)

-

82 mm (1)

-

84 mm (1)

-

90 mm (1)

-

94 mm (1)

-

14.601 mm (1)

-

29.5 mm (1)

-

X-TRIGON 82 (1)

-

3.975 mm (1)

-

0.156 in (1)

-

3.45 mm (1)

-

0.136 in (1)

-

B H (39)

-

B L (39)

-

C N (32)

-

D P (39)

-

H T (39)

-

H W (39)

-

G (1)

-

HSK63A (10)

-

KM32TS (4)

-

KM40TS (2)

-

KM50TS (5)

-

KM63TS (2)

-

KM80TS (5)

-

16.0 mm (28)

-

18.0 mm (1)

-

20.0 mm (1)

-

25.0 mm (1)

-

32.0 mm (4)

-

40.0 mm (2)

-

50.0 mm (5)

-

60.0 mm (6)

-

63.0 mm (12)

-

80.0 mm (5)

-

0.63 in (28)

-

0.709 in (1)

-

0.787 in (1)

-

0.984 in (1)

-

1.26 in (4)

-

1.575 in (2)

-

1.969 in (5)

-

2.362 in (6)

-

2.48 in (12)

-

3.15 in (5)