Produkt ähnlich wie:

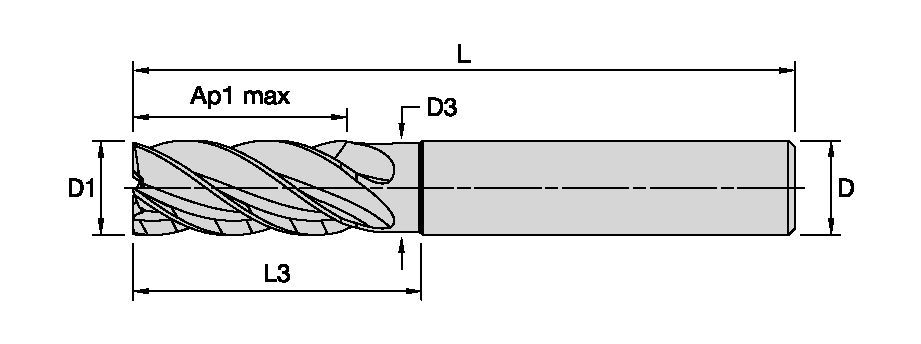

HARVI™ II TE • Square End • 5 Flutes • Necked • Plain Shank • Metric

HARVI™ II TE Five Flute End Mill for Increased MRR Covering the Broadest Range of Applications and Materials;

Roughing and Finishing with One Tool

Material Nummer7156179

ISO Katalog NummerH2TE5SE1000N022HAMANSI Katalog NummerH2TE5SE1000N022HAM

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 7156179 |

| ISO Katalog Nummer | H2TE5SE1000N022HAM |

| ANSI Katalog Nummer | H2TE5SE1000N022HAM |

| Sorte | KCPM15A |

| Aufnahmeart Maschinenseite | Straight-Cylindrical |

| [D1] Effektiver Schneidendurchmesser | 10 mm |

| [D1] Effektiver Schneidendurchmesser | 0.3937 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 10 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.3937 in |

| [D3] Halsdurchmesser | 9.4 mm |

| [D3] Halsdurchmesser | 0.3701 in |

| [AP1MAX] 1. maximale Schnitttiefe | 22 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.8661 in |

| [L3] Nutzbare Länge | 30 mm |

| [L3] Nutzbare Länge | 1.1811 in |

| [L] Gesamtlänge | 72 mm |

| [L] Gesamtlänge | 2.8346 in |

| [Z] Anzahl der Spannuten | 5 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

Features and benefits

- Versatile solid carbide endmill for steels, stainless steel, high temperature alloys, and cast iron.

- Proprietary core and flute designs with optimum flute spacing for perfect chip formation and highest tool rigidity.

- Unique End Face Design for agressive ramping and plunging operations.

- Unequally spaced flutes and differential helix allow for the broadest range of applications.

- Chip gashes in the flutes ensure optimum chip removal.

- Eccentric relief provides edge stability in a broad range of materials.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Geschwindigkeiten und Vorschübe

| Table for Feed and Speed Calculation with Adjustment Factor • INCH | |||||||||||||||||||||

|  | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | KCPM15 | D1 | |||||||||||||||||||

| A | B | Schnittgeschwindigkeit | frac. | 1/8 | 5/32 | 3/16 | 7/32 | 1/4 | 9/32 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||

| Werkstoffgruppe | ap | ae | ap | Min. | Startwert | Max. | dec. | .1250 | .1563 | .1875 | .2188 | .2500 | .2813 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | |

| P | P0 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | 575 | 660 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 |

| P1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | 575 | 660 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 | |

| P2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 460 | 540 | 620 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 | |

| P3 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 390 | 455 | 520 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 | |

| P4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | 395 | 490 | IPT | 0.0007 | 0.0009 | 0.0011 | 0.0013 | 0.0015 | 0.0017 | 0.0019 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0042 | 0.0044 | |

| P5 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | 265 | 330 | IPT | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0017 | 0.0020 | 0.0025 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | |

| P6 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | 205 | 250 | IPT | 0.0006 | 0.0007 | 0.0008 | 0.0010 | 0.0011 | 0.0013 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0027 | 0.0031 | 0.0032 | |

| M | M1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | 340 | 380 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 |

| M2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | 230 | 260 | IPT | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0017 | 0.0020 | 0.0025 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | |

| M | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 200 | 215 | 230 | IPT | 0.0006 | 0.0007 | 0.0008 | 0.0010 | 0.0011 | 0.0013 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0027 | 0.0031 | 0.0032 | |

| K | K1 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 390 | 440 | 490 | IPT | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0037 | 0.0043 | 0.0048 | 0.0054 | 0.0054 |

| K2 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | 410 | 460 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 | |

| K3 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | 395 | 430 | IPT | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0017 | 0.0020 | 0.0025 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | |

| S | S1 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | 230 | 300 | IPT | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0032 | 0.0038 | 0.0042 | 0.0050 | 0.0053 |

| S2 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 80 | 120 | 160 | IPT | 0.0004 | 0.0005 | 0.0007 | 0.0008 | 0.0009 | 0.0010 | 0.0011 | 0.0013 | 0.0017 | 0.0020 | 0.0023 | 0.0027 | 0.0029 | |

| S3 | 1.5 x D1 | 0.5 x D1 | 0.75 x D1 | 80 | 105 | 130 | IPT | 0.0004 | 0.0005 | 0.0007 | 0.0008 | 0.0009 | 0.0010 | 0.0011 | 0.0013 | 0.0017 | 0.0020 | 0.0023 | 0.0027 | 0.0029 | |

| S4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | 180 | 200 | IPT | 0.0005 | 0.0007 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0016 | 0.0019 | 0.0023 | 0.0028 | 0.0031 | 0.0036 | 0.0039 | |

| H | H1 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 260 | 360 | 460 | IPT | 0.0007 | 0.0009 | 0.0011 | 0.0013 | 0.0015 | 0.0017 | 0.0019 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0042 | 0.0044 |

| H2 | 1.5 x D1 | 0.2 x D1 | 1.0 x D1 | 230 | 310 | 390 | IPT | 0.0006 | 0.0007 | 0.0008 | 0.0010 | 0.0011 | 0.0013 | 0.0014 | 0.0017 | 0.0021 | 0.0025 | 0.0027 | 0.0031 | 0.0032 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on | |||||||||||||||||||||

| Table for Feed and Speed Calculation with Adjustment Factor • METRIC | |||||||||||||||||||||

|  | Empfohlener Vorschub pro Zahn (fz = mm/Zahn) zum Eckfräsen (A). | |||||||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | KCPM15 | D1 | |||||||||||||||||||

| A | B | Schnittgeschwindigkeit | |||||||||||||||||||

| Werkstoffgruppe | ap | ae | ap | Min. | Startwert | Max. | mm | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 25.0 | |

| P | P0 | 1.5 x D | 0.5 x D | 1.25 x D | 150 | 175 | 200 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 |

| P1 | 1.5 x D | 0.5 x D | 1.25 x D | 150 | 175 | 200 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 | |

| P2 | 1.5 x D | 0.5 x D | 1.25 x D | 140 | 165 | 190 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 | |

| P3 | 1.5 x D | 0.5 x D | 1.25 x D | 120 | 140 | 160 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 | |

| P4 | 1.5 x D | 0.5 x D | 1.25 x D | 90 | 120 | 150 | Fz | 0.024 | 0.030 | 0.036 | 0.043 | 0.049 | 0.054 | 0.059 | 0.069 | 0.077 | 0.084 | 0.091 | 0.097 | 0.107 | |

| P5 | 1.5 x D | 0.5 x D | 1.25 x D | 60 | 80 | 100 | Fz | 0.021 | 0.027 | 0.032 | 0.038 | 0.044 | 0.049 | 0.053 | 0.062 | 0.070 | 0.077 | 0.083 | 0.089 | 0.100 | |

| P6 | 1.5 x D | 0.5 x D | 1.25 x D | 50 | 63 | 75 | Fz | 0.018 | 0.022 | 0.027 | 0.032 | 0.037 | 0.041 | 0.044 | 0.051 | 0.057 | 0.063 | 0.067 | 0.071 | 0.078 | |

| M | M1 | 1.5 x D | 0.5 x D | 1.25 x D | 90 | 103 | 115 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 |

| M2 | 1.5 x D | 0.5 x D | 1.25 x D | 60 | 70 | 80 | Fz | 0.021 | 0.027 | 0.032 | 0.038 | 0.044 | 0.049 | 0.053 | 0.062 | 0.070 | 0.077 | 0.083 | 0.089 | 0.100 | |

| M3 | 1.5 x D | 0.5 x D | 1.0 x D | 60 | 65 | 70 | Fz | 0.018 | 0.022 | 0.027 | 0.032 | 0.037 | 0.041 | 0.044 | 0.051 | 0.057 | 0.063 | 0.067 | 0.071 | 0.078 | |

| K | K1 | 1.5 x D | 0.5 x D | 1.0 x D | 120 | 135 | 150 | Fz | 0.031 | 0.040 | 0.048 | 0.057 | 0.066 | 0.073 | 0.079 | 0.091 | 0.102 | 0.111 | 0.119 | 0.125 | 0.136 |

| K2 | 1.5 x D | 0.5 x D | 1.0 x D | 110 | 125 | 140 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 | |

| K3 | 1.5 x D | 0.5 x D | 1.0 x D | 110 | 120 | 130 | Fz | 0.021 | 0.027 | 0.032 | 0.038 | 0.044 | 0.049 | 0.053 | 0.062 | 0.070 | 0.077 | 0.083 | 0.089 | 0.100 | |

| S | S1 | 1.5 x D | 0.3 x D | 0.75 x D | 50 | 70 | 90 | Fz | 0.026 | 0.033 | 0.040 | 0.047 | 0.055 | 0.061 | 0.067 | 0.077 | 0.087 | 0.096 | 0.104 | 0.111 | 0.125 |

| S2 | 1.5 x D | 0.3 x D | 0.75 x D | 25 | 38 | 50 | Fz | 0.014 | 0.018 | 0.021 | 0.025 | 0.029 | 0.032 | 0.035 | 0.041 | 0.046 | 0.051 | 0.055 | 0.059 | 0.067 | |

| S3 | 1.5 x D | 0.5 x D | 0.75 x D | 25 | 33 | 40 | Fz | 0.014 | 0.018 | 0.021 | 0.025 | 0.029 | 0.032 | 0.035 | 0.041 | 0.046 | 0.051 | 0.055 | 0.059 | 0.067 | |

| S4 | 1.5 x D | 0.5 x D | 1.25 x D | 50 | 55 | 60 | Fz | 0.017 | 0.023 | 0.028 | 0.034 | 0.040 | 0.045 | 0.049 | 0.057 | 0.064 | 0.071 | 0.076 | 0.082 | 0.092 | |

| H | H1 | 1.5 x D | 0.5 x D | 1.0 x D | 80 | 110 | 140 | Fz | 0.024 | 0.030 | 0.036 | 0.043 | 0.049 | 0.054 | 0.059 | 0.069 | 0.077 | 0.084 | 0.091 | 0.097 | 0.107 |

| H2 | 1.5 x D | 0.2 x D | 1.0 x D | 70 | 95 | 120 | Fz | 0.018 | 0.022 | 0.027 | 0.032 | 0.037 | 0.041 | 0.044 | 0.051 | 0.057 | 0.063 | 0.067 | 0.071 | 0.078 | |

| These guidelines may require variations to achieve optimum results. Above parameters are based on ideal conditions. For smaller taper machining centers, please adjust parameters accordingly on | |||||||||||||||||||||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data