Product Similar To :

GOmill™ PRO • Chamfered • 4 Flutes • Plain Shank • Inch

Solid Carbide End Mill for Roughing and Finishing of Multiple Materials

Material Number7300367

ISO Catalog IDGOPR4CH0250R075HAANSI Catalog IDGOPR4CH0250R075HA

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Helical Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Shank - Cylindrical Plain

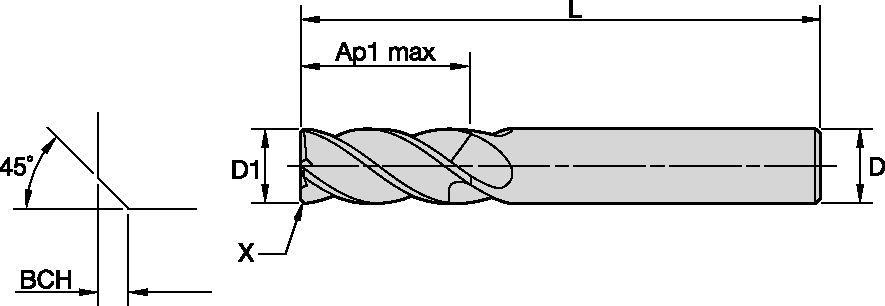

Corner Style: Corner Chamfer

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 7300367 |

| ISO Catalog ID | GOPR4CH0250R075HA |

| ANSI Catalog ID | GOPR4CH0250R075HA |

| Grade | KCU20 |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 6.35 mm |

| [D1] Effective Cutting Diameter | 0.25 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | 0.25 in |

| [AP1MAX] 1st Maximum Cutting Depth | 19.05 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.75 in |

| [L3] Usable Length | 22.955 mm |

| [L3] Usable Length | 0.9037 in |

| [L] Overall Length | 63.5 mm |

| [L] Overall Length | 2.5 in |

| [BCH] Corner Chamfer Width | 0.381 mm |

| [BCH] Corner Chamfer Width | 0.015 in |

| [Z] Number of Flutes | 4 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Uses and application

Helical Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Shank - Cylindrical Plain

Corner Style: Corner Chamfer

Features and benefits

- An asymmetric divided flute for better vibration control and tool life and smoother cutting

- A variable helix angle for better vibration control and tool life

- A tapered core for better chip evacuation and tool strength

- Multilayer TiN/TiAlN coating for high performance at medium-high cutting on steels, stainless steels and cast iron

- Special relief design for higher edge strength, better vibration control and workpiece material flexibility

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use