Product Similar To :

KDMR • Cylindrical Shank • Multi-Functional • Metric

Multifunctional Cutter

Material Number3587077

ISO Catalog IDKDMR40S32ANSI Catalog IDKDMR40S32

- P Steel

- M Stainless Steel

- .caption

Drilling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Shank - Cylindrical Plain

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 3587077 |

| ISO Catalog ID | KDMR40S32 |

| ANSI Catalog ID | KDMR40S32 |

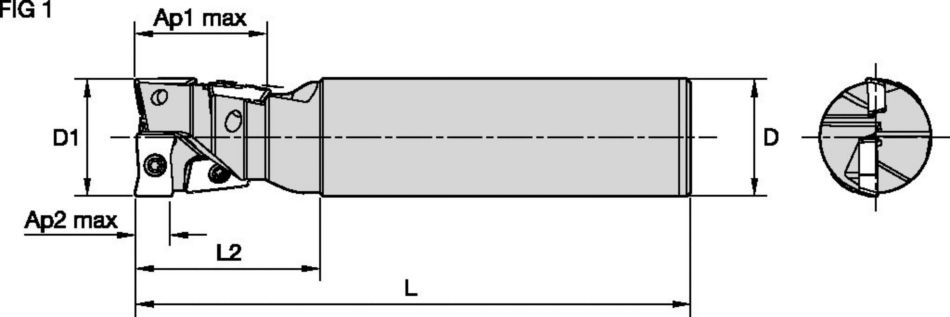

| [D1] Effective Cutting Diameter | 40 mm |

| [D1] Effective Cutting Diameter | 1.5748 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.2598 in |

| [L] Overall Length | 160 mm |

| [L] Overall Length | 6.2992 in |

| [L1] Gage Length | 160 mm |

| [L1] Gage Length | 6.2992 in |

| [L2] Head Length | 55 mm |

| [L2] Head Length | 2.1654 in |

| [AP1MAX] 1st Maximum Cutting Depth | 42 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.6535 in |

| [AP2MAX] 2nd Maximum Cutting Depth | 7.5 mm |

| [AP2MAX] 2nd Maximum Cutting Depth | 0.2953 in |

| Number of Inserts | 7 |

| [Z] Number of Flutes | 2 |

| Coolant Supply | N |

| KYC_CTLG_REF_ILLUS_NUM | FIG 2 |

| Weight Kilograms | 1.08 |

| Gage Insert | GOMT13T308ERLD |

| Gage Insert | JOMT13T308ERLF |

Workpiece Materials

- Steel

- Stainless Steel

- .caption

Uses and application

Drilling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Shank - Cylindrical Plain

Pocketing

Features and benefits

- Low cutting forces.

- Reduced shank diameters for access down long side walls.

- Excellent chip evacuation, even machining on an angle.

- When drilling, use (1) as the effective number of teeth (ZU).

- Milling to the maximum axial depth of (Ap2), we have (2) effective teeth.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .LD/.LF | 0,14 | 0,34 | 0,51 | 0,11 | 0,25 | 0,38 | 0,09 | 0,22 | 0,33 | 0,09 | 0,21 | 0,31 | 0,08 | 0,20 | 0,30 | .LD/.LF |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .LD/.LF | .006 | .014 | .020 | .004 | .010 | .015 | .004 | .009 | .013 | .003 | .008 | .012 | .003 | .008 | .012 | .LD/.LF |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KC505M | KC720M | |||||

| P | 1 | – | – | – | 260 | 240 | 215 |

| 2 | – | – | – | 240 | 215 | 190 | |

| 3 | – | – | – | 215 | 190 | 170 | |

| 4 | 360 | 260 | 215 | 190 | 180 | 170 | |

| 5 | 360 | 260 | 215 | 170 | 145 | 120 | |

| 6 | 350 | 240 | 190 | 120 | 95 | 95 | |

| M | 1 | – | – | – | 240 | 215 | 190 |

| 2 | – | – | – | 190 | 170 | 145 | |

| 3 | – | – | – | 145 | 120 | 95 | |

| K | 1 | 190 | 170 | 150 | – | – | – |

| 2 | 175 | 155 | 135 | – | – | – | |

| 3 | 115 | 95 | 75 | – | – | – | |

| N | 1–2 | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | KC505M | KC720M | |||||

| P | 1 | – | – | – | 860 | 790 | 710 |

| 2 | – | – | – | 790 | 710 | 630 | |

| 3 | – | – | – | 710 | 630 | 550 | |

| 4 | 1180 | 860 | 710 | 630 | 590 | 550 | |

| 5 | 1180 | 860 | 710 | 550 | 470 | 400 | |

| 6 | 1140 | 780 | 620 | 400 | 310 | 310 | |

| M | 1 | – | – | – | 780 | 710 | 630 |

| 2 | – | – | – | 630 | 550 | 470 | |

| 3 | – | – | – | 470 | 400 | 310 | |

| K | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .LD/.LF | KC720M | .LD/.LF | KC720M | .LD/.LF | KC720M |

| P3–P4 | .LD/.LF | KC720M | .LD/.LF | KC720M | .LD/.LF | KC720M |

| P5–P6 | .LD/.LF | KC720M | .LD/.LF | KC720M | .LD/.LF | KC720M |

| M1–M2 | .LD/.LF | KC720M | .LD/.LF | KC720M | .LD/.LF | KC720M |

| M3 | .LD/.LF | KC720M | .LD/.LF | KC720M | .LD/.LF | KC720M |

| K1–K2 | .LD/.LF | KC505M | .LD/.LF | KC505M | .LD/.LF | KC505M |

| K3 | .LD/.LF | KC505M | .LD/.LF | KC505M | .LD/.LF | KC505M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

TechnicalInfo

Drilling

| drilling | |

| cutting diameter | maximum depth (mm) |

| Ø 16 | 13 |

| Ø 17 | 13 |

| Ø 20 | 17 |

| Ø 21 | 17 |

| Ø 25 | 22 |

| Ø 26 | 22 |

| Ø 32 | 25 |

| Ø 33 | 25 |

| Ø 40 | 25 |

| Ø 50 | 25 |

Drilled Hole Bottom Shape

| Drilled Hole Bottom Shape | ||||||

| cutting diameter | Ø 16, Ø 17 | Ø 20, Ø 21 | Ø 25, Ø 26 | Ø 32, Ø 33 | Ø 40 | Ø 50 |

| A (mm) | 0,50 | 0,64 | 0,85 | 1,12 | 1,54 | 1,65 |

Ramping

| end mill | applicable insert for each cutter diameter | |||

| D1 | side Insert | quantity | center | quantity |

| Ø 16 | JOMT08T208ERLF | 3 | GOMT08T208ERLD | 1 |

| Ø 17 | JOMT08T208ERLF | 3 | GOMT08T208ERLD | 1 |

| Ø 20 | JOMT100308ERLF | 3 | GOMT100308ERLD | 1 |

| Ø 21 | JOMT100308ERLF | 3 | GOMT100308ERLD | 1 |

| Ø 25 | JOMT13T308ERLF | 3 | GOMT13T308ERLD | 1 |

| Ø 26 | JOMT13T308ERLF | 3 | GOMT13T308ERLD | 1 |

| Ø 32 | JOMT160408ERLF | 3 | GOMT160408ERLD | 1 |

| Ø 33 | JOMT160408ERLF | 3 | GOMT160408ERLD | 1 |

| Ø 40 | JOMT13T308ERLF | 6 | GOMT13T308ERLD | 1 |

| Ø 50 | JOMT160408ERLF | 6 | GOMT160408ERLD | 1 |

I have read and accepted the Terms & Conditions of use