Producto similar a:

Plaquitas para TMS • Fresado de rosca • Exterior • Rosca ISO

Plaquitas intercambiables • Perfiles de rosca

Número de material1138113

Referencia ISOSTN27150ISOEReferencia ANSISTN27150ISOE

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Número de material | 1138113 |

| Referencia ISO | STN27150ISOE |

| Referencia ANSI | STN27150ISOE |

| Calidad | KC620M |

| Paso de la rosca | 1,5 mm |

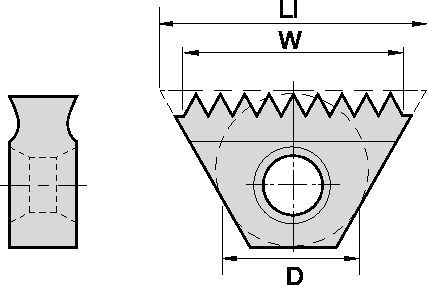

| Tamaño IC de plaquita [D] | 15.875 mm |

| Tamaño IC de plaquita [D] | 0.625 in |

| Longitud de plaquita [LI] | 26.924 mm |

| Longitud de plaquita [LI] | 1.06 in |

| Ancho de corte [W] | 25.4 mm |

| Ancho de corte [W] | 1 in |

| Número de dientes | 17 |

Grades

KC620M

Coated carbide grade with a PVD coat (TiN). Coated carbide grade with a PVD coat (TiN). KC620M is suitable for machining cast iron, non-ferrous material, Aluminum alloys. This grade is suitable for both wet and dry machining. suitable for machining cast iron, non-ferrous material, aluminum alloys. This grade is suitable for both wet and dry machining.

Features and benefits

- Estilo de rosca de tornillo métrica ISO.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Datos de aplicación

STN Series

| Materiales | Brinell | velocidades superficiales | Plaquitas intercambiables | |

| Acero | HB | KC610M | KC635M | avance fz (IPT) |

| P1 | 125 | 325–675 | 290–590 | .002–.008 |

| P2 | 180 | 290–550 | 290–520 | .002–.008 |

| P3 | 225 | 200–425 | 225–375 | .002–.008 |

| P4 | 250 | 250–490 | 250–500 | .002–.008 |

| P5 | 275 | 250–425 | 250–500 | .002–.006 |

| P6 | 325 | 225–350 | 200–325 | .002–.004 |

| Acero inoxidable | ||||

| M1 | 180 | 325–550 | 375–590 | .002–.004 |

| M2 | 250 | 225–450 | 325–450 | .002–.004 |

| M3 | 330 | 225–375 | 325–375 | .002–.004 |

| Fundición | ||||

| K1 | 180 | 200–425 | 325–450 | .001–.003 |

| K2 | 220 | 200–390 | 250–325 | .002–.006 |

| K3 | 260 | 160–290 | 200–275 | .002–.004 |

| Materiales no ferrosos | ||||

| N1 | 60–100 | 325–820 | – | .002–.010 |

| Aleaciones de alta temperatura | ||||

| S1 | 200 | 65–140 | 65–130 | .002–.004 |

| S2 | 250 | 65–90 | 65–90 | .001–.002 |

| S3 | 280 | 50–65 | 50–65 | .001–.002 |

| S4 | 350 | 30–50 | 30–50 | .001–.002 |

| acero endurecido | ||||

| H1 | 55HRc | 65–140 | 65–140 | .0004–.001 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data