Producto similar a:

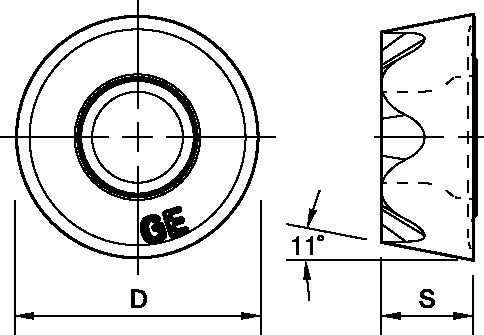

Round Inserts for KSRM • IC 1/2" • RPPT-SGE

Indexable Inserts

Número de material5172844

Referencia ISORPPT43SGEReferencia ANSIRPPT43SGE

- P Acero

- M Acero inoxidable

- S Aleaciones de alta temperatura

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 5172844 |

| Referencia ISO | RPPT43SGE |

| Referencia ANSI | RPPT43SGE |

| Calidad | KC725M |

| Tamaño IC de plaquita [D] | 12.7 mm |

| Tamaño IC de plaquita [D] | 0.5 in |

| Grosor de plaquita [S] | 4.76 mm |

| Grosor de plaquita [S] | 0.188 in |

| Grosor medio de las virutas [HM] | 0.114 mm |

| Grosor medio de las virutas [HM] | 0.0045 in |

| Número de posiciones plaquita | 6 |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Aleaciones de alta temperatura

Grades

KC725M

Qualità in metallo duro rivestito PVD TiAlN avanzato. KC725M è una qualità ad alte prestazioni per la fresatura di acciaio, acciaio inossidabile e leghe resistenti alle alte temperature. La buona resistenza agli shock termici del substrato rende questa qualità ideale per lavorazioni a secco e a umido. Da utilizzare principalmente per lavorazioni generali e pesanti.

Features and benefits

- -SGE geometry for general purpose in roughing operations in steel.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Feeds

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .003 | .005 | .007 | .003 | .004 | .005 | .002 | .003 | .005 | .002 | .003 | .004 | .002 | .003 | .004 | .E..LEJ |

| .E..GE | .006 | .010 | .015 | .004 | .008 | .011 | .004 | .007 | .010 | .004 | .006 | .009 | .004 | .006 | .009 | .E..GE |

| .S..GEJ | .007 | .017 | .023 | .005 | .013 | .017 | .004 | .011 | .015 | .004 | .010 | .014 | .004 | .010 | .014 | .S..GEJ |

| .S..GE | .007 | .017 | .023 | .005 | .013 | .017 | .004 | .011 | .015 | .004 | .010 | .014 | .004 | .010 | .014 | .S..GE |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .004 | .006 | .008 | .003 | .004 | .006 | .003 | .004 | .005 | .002 | .003 | .005 | .002 | .003 | .005 | .E..LEJ |

| .E..GE | .007 | .012 | .017 | .005 | .009 | .013 | .004 | .008 | .011 | .004 | .007 | .010 | .004 | .007 | .010 | .E..GE |

| .S..GEJ | .008 | .020 | .027 | .006 | .015 | .020 | .005 | .013 | .017 | .005 | .012 | .016 | .005 | .012 | .016 | .S..GEJ |

| .S..GE | .008 | .020 | .027 | .006 | .015 | .020 | .005 | .013 | .017 | .005 | .012 | .016 | .005 | .012 | .016 | .S..GE |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .007 | .010 | .015 | .005 | .007 | .011 | .005 | .006 | .009 | .004 | .006 | .009 | .004 | .006 | .009 | .E..LEJ |

| .E..GE | .012 | .021 | .031 | .009 | .016 | .023 | .008 | .014 | .020 | .007 | .013 | .018 | .007 | .012 | .018 | .E..GE |

| .S..GEJ | .014 | .036 | .049 | .010 | .026 | .035 | .009 | .023 | .031 | .008 | .021 | .028 | .008 | .021 | .028 | .S..GEJ |

| .S..GE | .014 | .036 | .049 | .010 | .026 | .035 | .009 | .023 | .031 | .008 | .021 | .028 | .008 | .021 | .028 | .S..GE |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LEJ | .005 | .007 | .011 | .004 | .005 | .008 | .003 | .005 | .007 | .003 | .004 | .006 | .003 | .004 | .006 | .E..LEJ |

| .E..GE | .009 | .015 | .023 | .007 | .011 | .017 | .006 | .010 | .014 | .005 | .009 | .014 | .005 | .009 | .013 | .E..GE |

| .S..GEJ | .010 | .026 | .035 | .008 | .019 | .026 | .007 | .017 | .022 | .006 | .015 | .021 | .006 | .015 | .020 | .S..GEJ |

| .S..GE | .010 | .026 | .035 | .008 | .019 | .026 | .007 | .017 | .022 | .006 | .015 | .021 | .006 | .015 | .020 | .S..GE |

Speeds

Recommended Starting Speeds [SFM]

| Grupo de materiales | KC422M | KC522M | KC725M | KCPK30 | |||||||||

| P | 1 | – | – | – | 1300 | 1130 | 1060 | 1030 | 900 | 840 | 1780 | 1560 | 1450 |

| 2 | – | – | – | 1080 | 950 | 790 | 860 | 760 | 640 | 1100 | 1000 | 900 | |

| 3 | – | – | – | 1000 | 840 | 700 | 790 | 670 | 550 | 1000 | 900 | 820 | |

| 4 | – | – | – | 890 | 730 | 590 | 710 | 590 | 470 | 740 | 690 | 620 | |

| 5 | – | – | – | 730 | 660 | 590 | 590 | 530 | 470 | 1020 | 910 | 830 | |

| 6 | – | – | – | 650 | 490 | 400 | 520 | 400 | 310 | 620 | 540 | – | |

| M | 1 | – | – | – | 800 | 710 | 650 | 670 | 590 | 540 | 820 | 720 | 620 |

| 2 | – | – | – | 730 | 620 | 520 | 610 | 520 | 430 | 730 | 640 | 550 | |

| 3 | – | – | – | 550 | 480 | 370 | 460 | 400 | 310 | 570 | 520 | 460 | |

| K | 1 | – | – | – | 900 | 820 | 720 | – | – | – | 1160 | 1050 | 940 |

| 2 | – | – | – | 710 | 640 | 590 | – | – | – | 920 | 830 | 760 | |

| 3 | – | – | – | 590 | 530 | 480 | – | – | – | 770 | 690 | 640 | |

| N | 1–2 | 4220 | 3720 | 3440 | – | – | – | – | – | – | – | – | – |

| 3 | 3720 | 3440 | 3000 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – |

| 2 | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | |

| 3 | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | – | – | – | |

| 4 | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | – | – | – | |

| H | 1 | – | – | – | 470 | 360 | 280 | – | – | – | – | – | – |

Datos de aplicación

Maximum Linear Ramping and Helical Interpolation from Solid

| número de catálogo | Maximum Ramp Angle (ra) when hx = .01" and ae | Maximum Ramp Depth (ap) per pass when ae | Maximum Ramp Depth (ap) per pass when hx = .01" and ae ae1 | ae1 | Maximum Plunge Depth (ap) when hx = .01" and ae | ae2 | mín. diámetro agujero (DH mín.) | máx. diámetro agujero fondo plano (DH1 máx.) | Maximum Hole Diameter (No Flat Bottom) |

| KSRM125R4303C125L600 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302C125L600 | 5.95° | 0.061 | 0.250 | 0.413 | 0.250 | 0.500 | 1.674 | 2.001 | 2.500 |

| KSRM125R4303C125L1000 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302C125L1000 | 5.95° | 0.061 | 0.250 | 0.413 | 0.250 | 0.500 | 1.674 | 2.001 | 2.500 |

| KSRM150R4304C125L600 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303C125L600 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM150R4304C125L1000 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303C125L1000 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM125R4303M16L150 | 5.30° | 0.055 | 0.250 | 0.406 | 0.250 | 0.500 | 1.688 | 2.001 | 2.500 |

| KSRM125R4302M16L150 | 6.43° | 0.065 | 0.250 | 0.418 | 0.250 | 0.500 | 1.665 | 2.001 | 2.500 |

| KSRM150R4304M16L150 | 4.74° | 0.069 | 0.250 | 0.421 | 0.250 | 0.500 | 2.157 | 2.502 | 3.000 |

| KSRM150R4303M16L150 | 5.31° | 0.077 | 0.250 | 0.429 | 0.250 | 0.500 | 2.142 | 2.502 | 3.000 |

| KSRM200R4305S075L197 | 11.43° | 0.250 | 0.250 | 0.499 | 0.250 | 0.500 | 3.001 | 3.501 | 4.000 |

| KSRM200R4303S075L197 | 11.45° | 0.250 | 0.250 | 0.499 | 0.250 | 0.500 | 3.001 | 3.501 | 4.000 |

| KSRM250R4306S075L197 | 8.16° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 4.001 | 4.500 | 5.000 |

| KSRM250R4304S075L197 | 8.16° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 4.001 | 4.500 | 5.000 |

| KSRM300R4307S100L197 | 6.35° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 5.001 | 5.500 | 6.000 |

| KSRM300R4305S100L197 | 6.35° | 0.250 | 0.250 | 0.500 | 0.250 | 0.500 | 5.001 | 5.500 | 6.000 |

Insert Selection

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..LEJ | KC725M | .E..GE | KC725M | .S..GE | KCPK30 |

| P3–P4 | .E..LEJ | KC725M | .S..GE | KCPK30 | – | – |

| P5–P6 | .E..GE | KCPK30 | .S..GE | KCPK30 | – | – |

| M1–M2 | .E..LEJ | KC725M | .E..LEJ | KC725M | .S..GE | KC725M |

| M3 | .S..GEJ | KC725M | .E..GE | KC725M | .S..GE | KCPK30 |

| K1–K2 | – | – | .S..GE | KCPK30 | – | – |

| K3 | – | – | .S..GE | KCPK30 | – | – |

| N1–N2 | .E..LEJ | KC422M | .E..LEJ | KC422M | .E..LEJ | KC422M |

| N3 | .E..LEJ | KC422M | .E..LEJ | KC422M | .E..LEJ | KC422M |

| S1–S2 | .E..LEJ | KC725M | .S..GEJ | KC725M | .S..GE | KC725M |

| S3 | .E..LEJ | KC725M | .S..GEJ | KC725M | .S..GE | KC725M |

| S4 | .E..LEJ | KC725M | .E..GE | KC725M | .S..GE | KC725M |

| H1 | – | – | .S..GE | KC522M | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data